Randomly cleaned hollow flat sheet membrane component

A flat membrane and module technology, used in membrane technology, semi-permeable membrane separation, biological water/sewage treatment, etc., can solve the problem of low cleaning effect of surface colloidal substances, difficult to remove colloidal substances and bacteria, waste of time and purifying water. and other problems, to achieve the effect of improving the filtration effect and filtration efficiency, increasing the effluent flux, and increasing the working time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

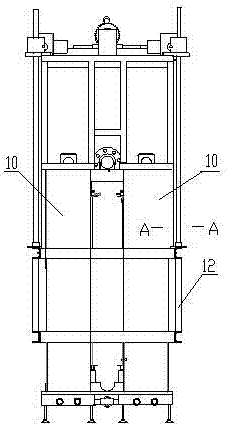

[0021] Example 1, in figure 1 , figure 2 , image 3 and Figure 4 Among them, the hollow flat-plate membrane module that can be cleaned randomly includes a module frame and a flat-plate membrane module, the module frame is a rigid structure for fixing the flat-plate membrane module and the aeration mechanism, and the flat-plate membrane module includes an interval setting The flat diaphragm 10 (including organic and inorganic ceramic flat diaphragms), the upper plug and the lower plug (not shown in the figure) integrated with the flat diaphragm, the upper part of the module frame is provided with a support frame 8, so The support frame is installed above the flat membrane module 11, and the support frame is provided with a lifting mechanism 1, and the lifting mechanism is respectively equipped with a turbine screw rod 2, and the rotation of the lifting mechanism drives the turbine screw rod 2 to move up and down, and a gear converter is arranged in the middle 3. A motor 5 ...

Embodiment 2

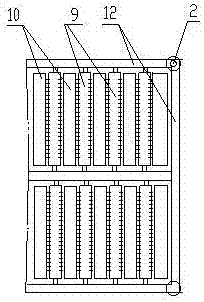

[0022] Example 2, such as Figure 5 As shown, the support frame with the beam in the middle is provided with elongated brushes 9 made of soft or hard bristles at intervals, and the brushes are used to mechanically reciprocate on the surface of the regular flat plate diaphragm 10. The surface of the diaphragm is brushed. Guide rails 15 are arranged around the frame of the module, and bearings 16 are arranged on the support bracket 12. The bearings can move on the rails. Nuts are arranged on the beams. 1 screw, with a motor on the top of the component, the motor drives the screw to rotate, so that the nut on the screw drives the support bracket to reciprocate up and down, and cleans the two sides of the flat diaphragm in real time. The pollutants on the surface of the flat diaphragm are removed in time. The cross-sectional shape of the brush is circular, oval, waist-shaped, square, rectangular, etc., and the center of the brush is formed by winding 2-3 stainless steel wires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com