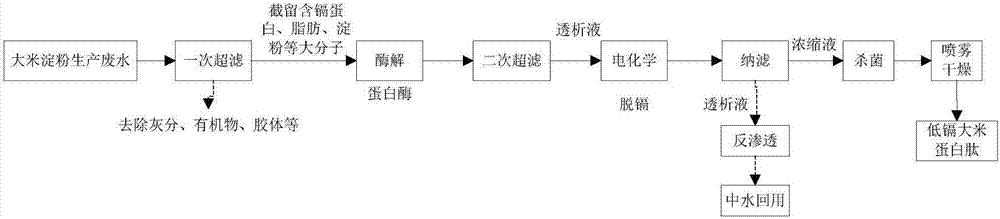

Method for synergistically preparing low-cadmium rice protein peptide by utilizing composite membrane and electrochemistry

A rice protein peptide and electrochemical technology, applied in the field of rice protein peptide and reclaimed water reuse, can solve the problems of low cadmium protein, unpreparable, unusable by-products, etc., and achieve the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

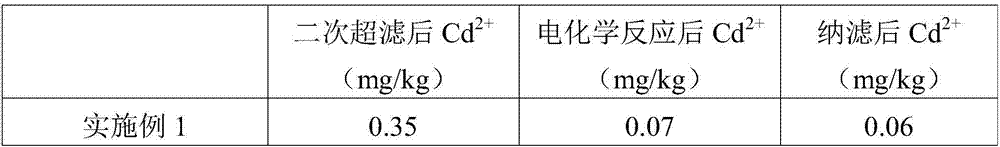

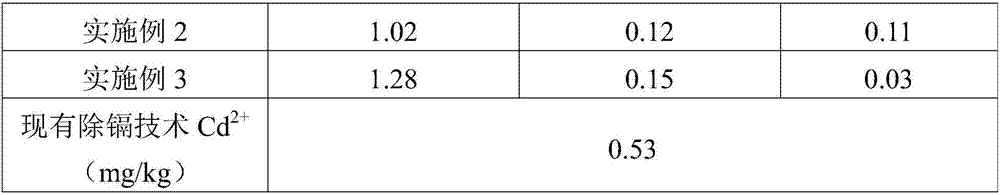

Embodiment 1

[0033] (1) Sampling of rice starch production wastewater: Take the wastewater produced in the rice starch production process, wherein the solid content is 4.0%, the conductivity is 1050 μs / cm, the protein content is 6.5% on a dry matter basis, and the cadmium ion content is 0.5mg / kg.

[0034] (2) Primary ultrafiltration: Pass the wastewater through a porous ultrafiltration membrane to remove ash, organic matter, and colloidal small molecule substances. The pore size is 0.05 μm, the operating pressure is 0.1 MPa, and the temperature of the feed liquid before entering the membrane is 15 ° C; The solid content of the ultrafiltration membrane concentrate is 2.5%, the electrical conductivity is 1800 μs / cm, and the protein content is 10.0% based on dry matter.

[0035] (3) Enzymolysis: Add papain to the concentrated solution in the ultrafiltration membrane in step (2) for enzymolysis, stir and react at 50°C for 4h, the added amount is 1‰ of the dry matter, and the stirring speed is...

Embodiment 2

[0043] (1) Sampling of rice starch production wastewater: Take the wastewater produced in the rice starch production process, wherein the solid content is 7.0%, the electrical conductivity is 1325μs / cm, the protein content is 9.3% in dry matter, and the cadmium ion content is 1.2mg / kg.

[0044] (2) Primary ultrafiltration: pass the wastewater through a porous ultrafiltration membrane to remove ash, organic matter, and colloidal small molecule substances. The pore size is 0.52 μm, the operating pressure is 0.31 MPa, and the temperature of the feed liquid before entering the membrane is 30 ° C; The solid content of the ultrafiltration membrane concentrate is 4.2%, the electrical conductivity is 2125 μs / cm, and the protein content is 15.2% based on dry matter.

[0045] (3) Enzymolysis: Add cathepsin to the concentrated solution in the ultrafiltration membrane in step (2) for enzymolysis, stir and react at 60°C for 2h, the added amount is 3‰ of the dry matter, and the stirring sp...

Embodiment 3

[0053] (1) Sampling of rice starch production wastewater: Take the wastewater produced in the rice starch production process, wherein the solid content is 10.0%, the conductivity is 1600μs / cm, the protein content is 12% on a dry matter basis, and the cadmium ion content is 1.8mg / kg.

[0054] (2) Primary ultrafiltration: the waste water is passed through a porous ultrafiltration membrane to remove ash, organic matter, and small colloidal molecules. The solid content of the membrane concentrate is 6.0%, the electrical conductivity is 2450 μs / cm, and the protein content is 20.5% based on dry matter.

[0055] (3) Enzymolysis: Add trypsin to the concentrated solution in the ultrafiltration membrane in step (2) for enzymolysis, stir and react at 70°C for 6h, the added amount is 5‰ of the dry matter, and the stirring speed is 150rpm.

[0056] (4) Secondary ultrafiltration: pass the enzymatic solution through the hollow fiber ultrafiltration membrane again, and retain starch, fat an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com