Burr removing device and method for cross deep oil hole with large ratio of length to diameter

A large aspect ratio, burr removal technology, applied in surface polishing machine tools, machine tools suitable for grinding workpiece edges, grinding machines, etc., can solve the problems of high labor intensity, low production efficiency, poor cleanliness of deep holes, etc. Achieve the effect of meeting mass production requirements, improving production efficiency, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

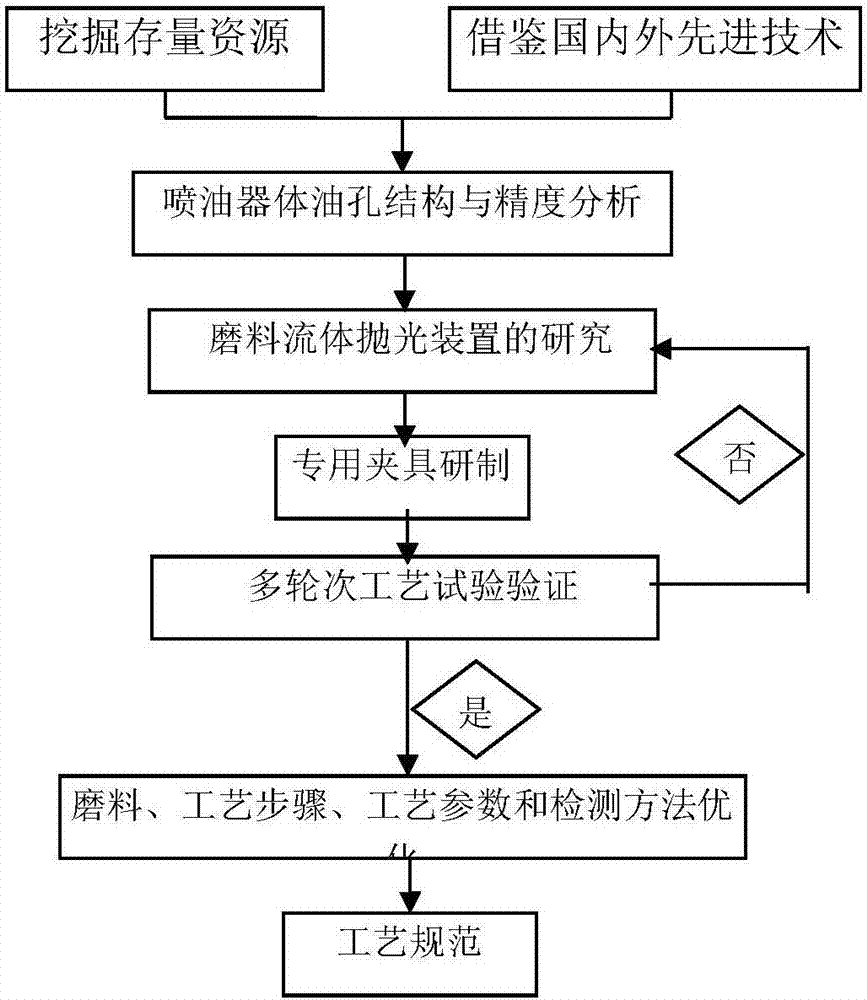

[0034] (1) overall design scheme of the present invention

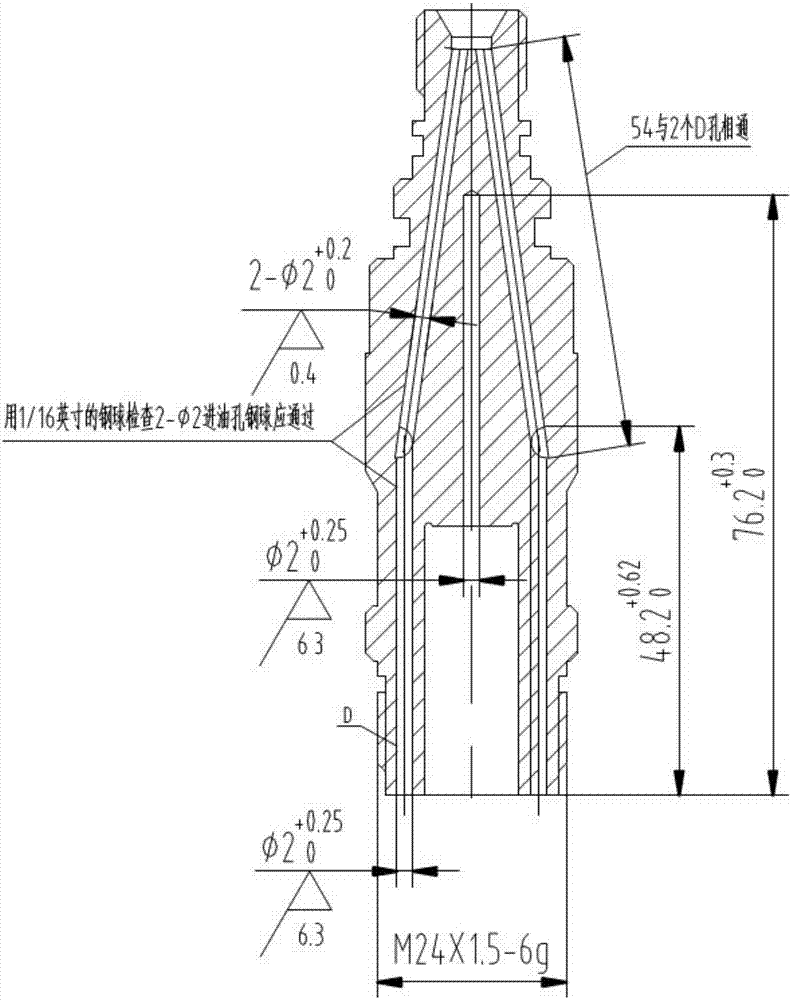

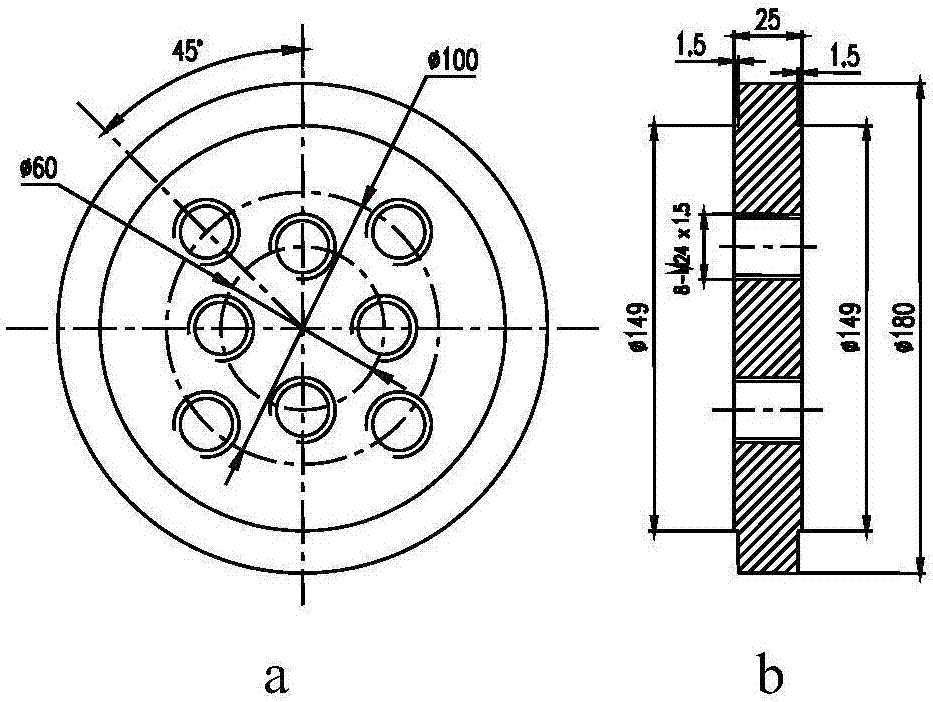

[0035] Fully excavate and utilize the existing resources, learn from the advanced manufacturing technology of fuel injection systems at home and abroad, start from digesting and absorbing the manufacturing technology of fuel injection systems for diesel engines in the future, and focus on improving the cleanliness of diesel engines, and design deep-hole abrasive fluid polishing for injector bodies For the overall technical scheme, see the overall invention scheme flow figure 2 . Mainly according to the oil hole structure and precision requirements of the injector body, a suitable oil hole abrasive fluid polishing device is developed. An elastic fluid grindin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com