A method for producing high-efficiency protein feed with feed enzymes cooperating with Bacillus coagulans

A technology of Bacillus coagulans and protein feed, which is applied in the field of biotechnology fermentation to achieve the effects of reducing production costs, improving health, and improving the body's immunity and disease resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

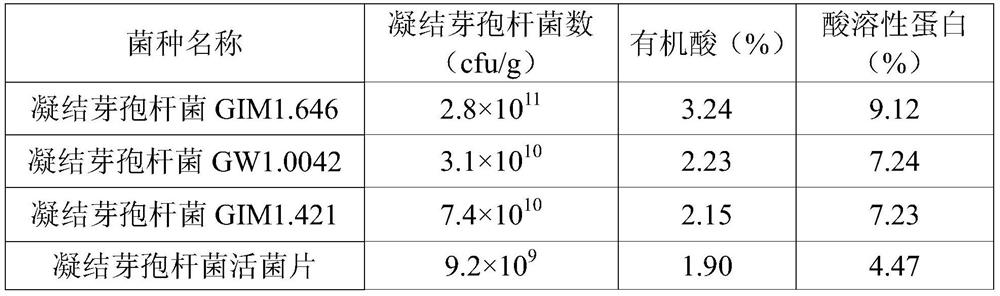

Embodiment 1

[0044] Implement as follows: the following components are calculated by mass percentage

[0045] (1) Preparation of Bacillus coagulans seed solution from different sources: pick one ring of Bacillus coagulans slant, inoculate it into a 250mL Erlenmeyer flask filled with 100mL LB liquid medium, cultivate it on a shaking table at 37°C, 180r / min for 6h, and make seeds liquid;

[0046] (2) Bacillus coagulans liquid culture: medium formula: yeast powder: 15g / L, sodium chloride: 5g / L, maltose: 8g / L, starch: 15g / L, magnesium sulfate: 0.8g / L, manganese sulfate : 0.2g / L, disodium hydrogen phosphate: 1g / L, sodium dihydrogen phosphate: 3g / L, initial pH value: 7.4. When cultivating, the liquid volume of the fermentation tank is 40%, the volume of seed liquid is 3%, the rotation speed is 160r / min, and the ventilation volume is 0.6m 3 / h, cultivated at 35°C for 18h;

[0047] (3) Solid-state culture of Bacillus coagulans: material (soybean meal: bran = 1:9) and the bacterial solution obta...

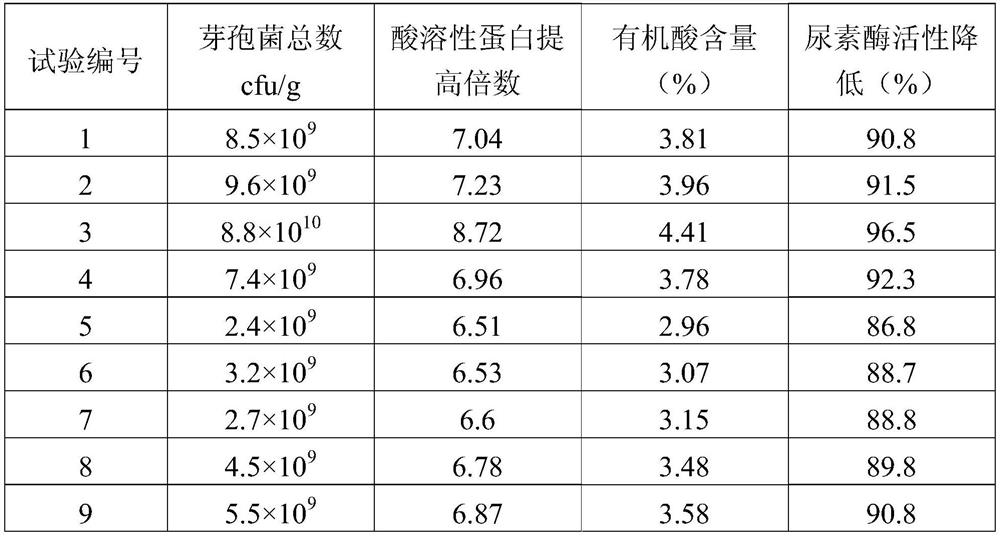

Embodiment 2

[0059] Implement as follows: the following components are calculated by mass percentage

[0060] (1) Preparation of Bacillus coagulans (Bacillus coagulans GIM1.646) seed solution: pick 1 ring of Bacillus coagulans slant, inoculate it into a 250mL Erlenmeyer flask containing 100mL LB liquid medium, shake the table at 37°C, 180r / min Cultivate for 6 hours to make seed solution;

[0061] (2) Bacillus coagulans liquid culture: medium formula: yeast powder: 30g / L, peptone: 10g / L, sodium chloride: 1g / L, disodium hydrogen phosphate: 5g / L, maltose, starch, magnesium sulfate, Manganese sulfate content design test (see Table 2), initial pH value: 6.8. When cultivating, the liquid volume of the fermentation tank is 20%, the seed liquid volume is 2%, the rotation speed is 200r / min, and the ventilation volume is 0.6m 3 / h, cultivated at 39°C for 20h;

[0062] Table 2 Design experiment of content of maltose, starch, magnesium sulfate and manganese sulfate

[0063] Test No. A M...

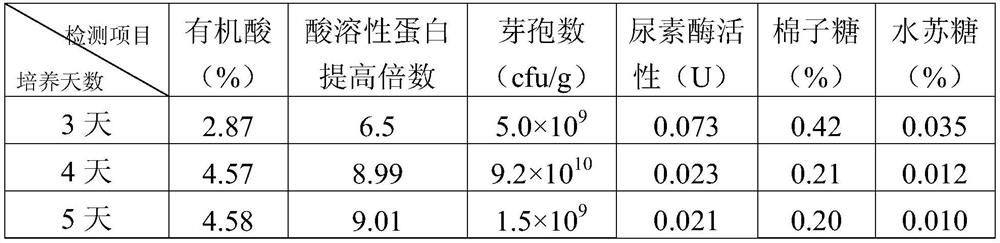

Embodiment 3

[0074] Implement as follows: the following components are calculated by mass percentage

[0075] (1) Preparation of Bacillus coagulans (Bacillus coagulans GIM1.646) seed solution: pick 1 ring of Bacillus coagulans slant, inoculate it into a 250mL Erlenmeyer flask containing 100mL LB liquid medium, shake the table at 37°C, 180r / min Cultivate for 6 hours to make seed solution;

[0076] (2) Bacillus coagulans liquid culture: medium formula: yeast powder: 25g / L, peptone: 5g / L, sodium chloride: 2g / L, maltose: 6g / L, starch: 20g / L, magnesium sulfate: 1.2 g / L, manganese sulfate: 0.3g / L, disodium hydrogen phosphate: 3g / L, sodium dihydrogen phosphate: 5g / L, initial pH value: 7.2. When cultivating, the liquid volume of the fermentation tank is 60%, the seed liquid volume is 1%, the rotation speed is 120r / min, and the ventilation volume is 0.6m 3 / h, cultivated at 37°C for 15h;

[0077] (3) Solid-state culture of Bacillus coagulans: material (soybean meal: bran = 1:9) and the bacterial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com