Multipurpose straw gleaning bundling machine

A baler, multi-purpose technology, applied in the direction of applications, loaders, agricultural machinery and tools, etc., can solve the problems of reducing the utilization rate of straw picking and baling machines, and the length or soil content requirements are not strict, so as to achieve the reduction of straw Soil content rate, reducing weed blocking phenomenon, and shortening the effect of blowing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

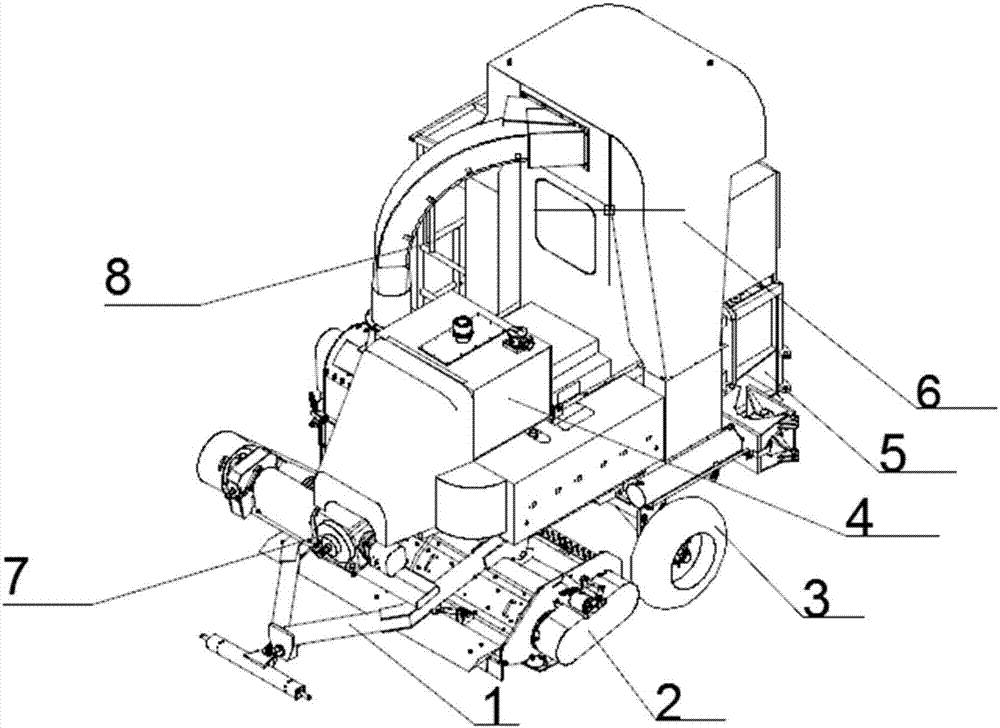

[0028] In this embodiment, a kind of multi-purpose straw picking and bundling machine, such as figure 1 As shown, it mainly includes: vehicle frame 1, picker 2, collecting box 6, operating room 8, transmission device 7, and baler 5.

[0029] The picker 2 is hoisted and fixed below the vehicle frame 1, the baler 5 is installed in the vehicle frame 1, and the collecting box 6 is located at the rear of the vehicle frame 1 above the baler 5; the transmission device 7 is fixed on the front end of the vehicle frame 1 The operating room 8 is arranged on one side of the vehicle frame 1 , and the traveling wheels 3 are arranged under the vehicle frame 1 .

[0030] The transmission device 7 is connected to the power output end of the tractor tail that pulls the straw picking and bundling machine; Output to the pickup 7 to provide power for the pickup 7; the controller of the hydraulic cylinder of the baler 5 is set in the operating room 8;

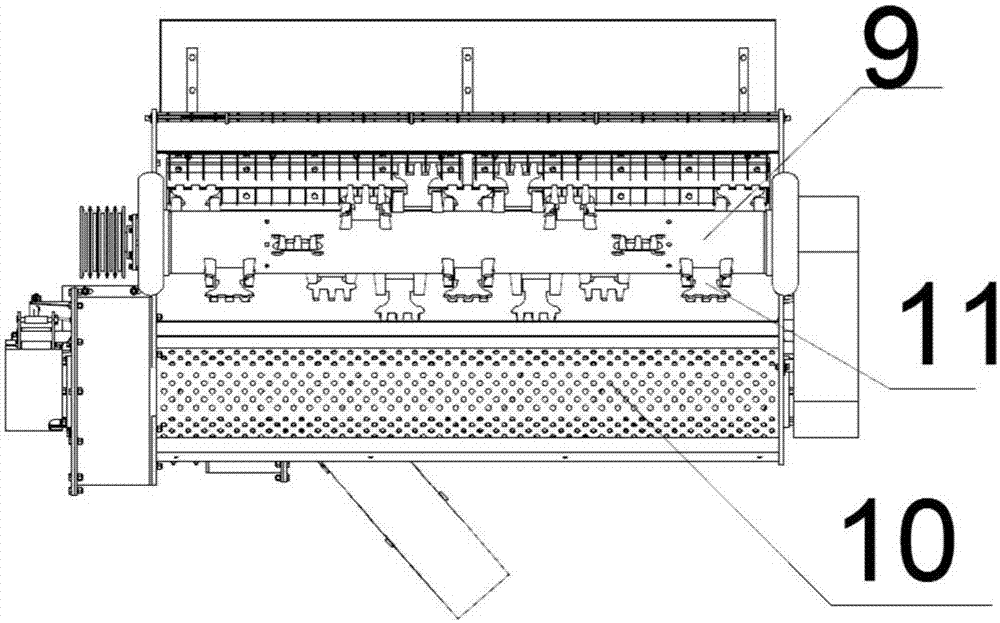

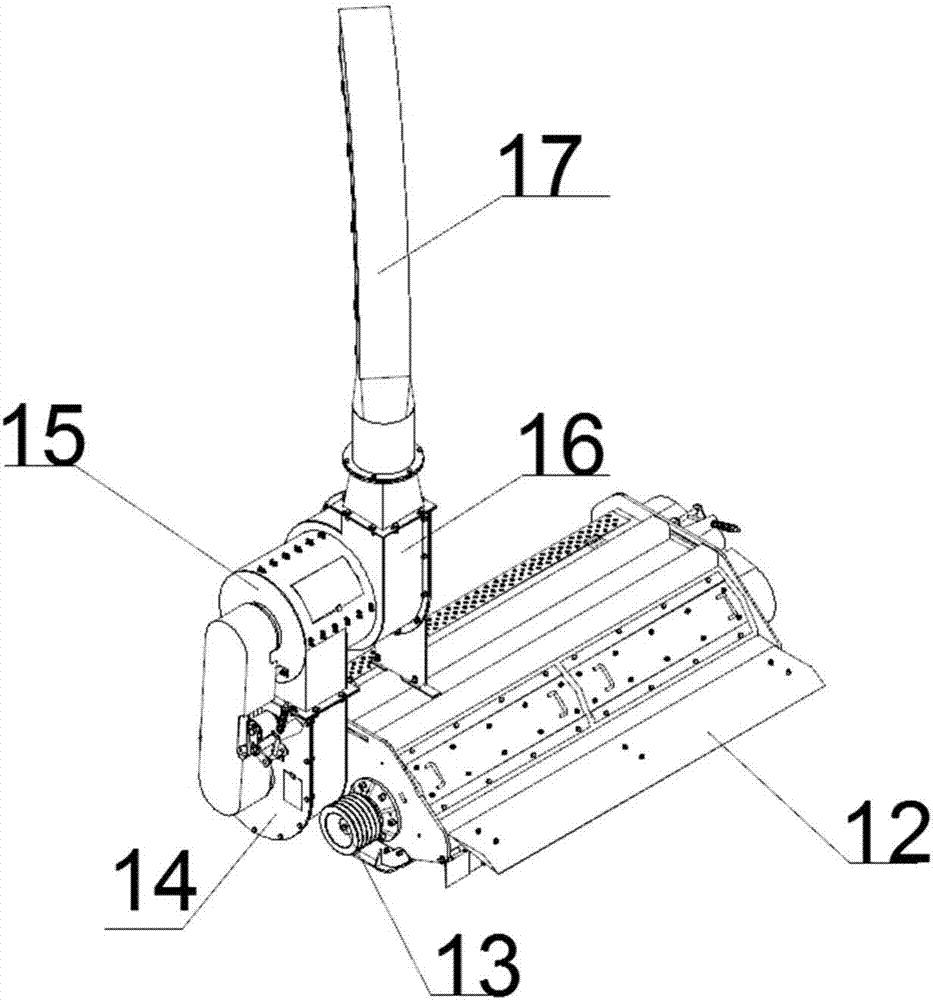

[0031] Such as Figure 2 ~ Figure 4 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com