Perovskite crystal composite material, and preparation method and application thereof

A composite material, perovskite technology, applied in the field of solar cells, can solve problems such as poor moisture resistance, achieve the effects of good stability, improved thermal stability and deliquescence resistance, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A preparation method of a perovskite crystal composite material, comprising the steps of:

[0048] S1. The organic dopant is added to the perovskite crystal solution and mixed to form a mother liquor.

[0049] Wherein, the perovskite crystal solution refers to a solution formed by dissolving perovskite crystals in the first solvent. Preferably, the first solvent is selected from one or more of dimethylformamide, dimethyl sulfoxide, and γ-butyrolactone.

[0050] Preferably, in step S1, the molar ratio of the organic dopant to the perovskite crystal solution is 1:15˜1:3.

[0051] S2. Crystallizing the mother liquor to obtain a perovskite crystal composite material.

[0052] Preferably, the crystallization is evaporation crystallization. More preferably, the heating temperature is 90-120°C.

[0053] In a preferred embodiment, the specific operation is that the mother liquor is transferred to a crystallization dish, and then the crystallization dish is placed on an elec...

Embodiment 1

[0088] The organic dopant (tetraethylenepentamine) was added to 20mL of 1mol / L (MAPbI 3 ) / γ-butyrolactone solution to form a mother liquor.

[0089] The mother liquor was transferred to a crystallization dish, heated on a 100°C electric heating plate, evaporated and crystallized for 48 hours, and a perovskite crystal composite material was obtained, which was designated as A1.

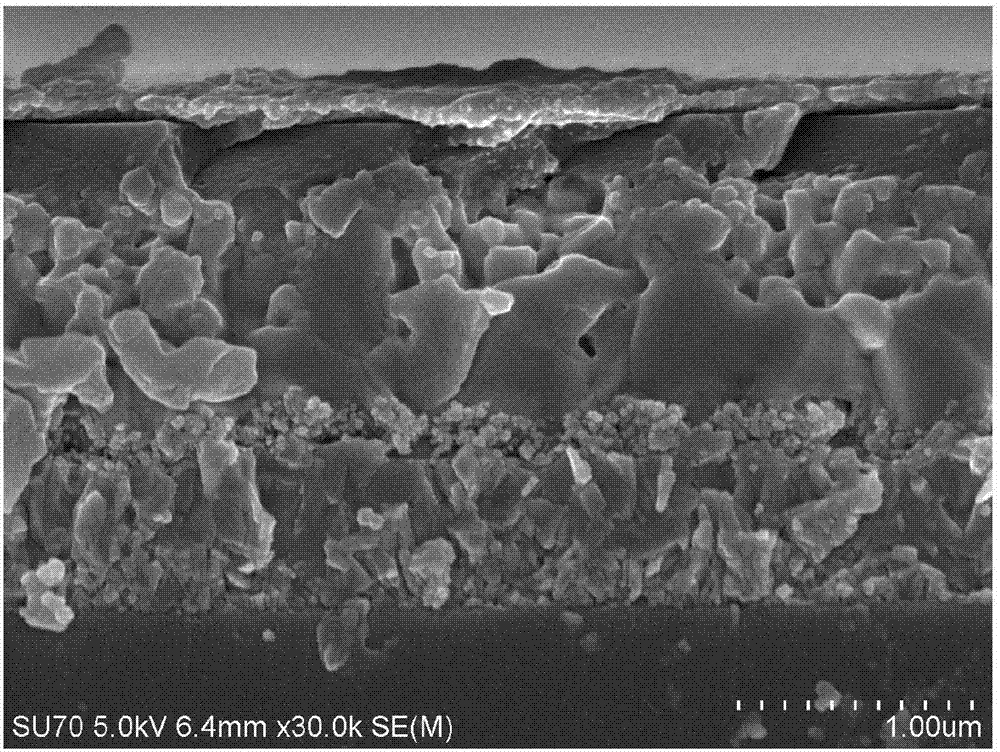

[0090] Add the single crystal particles of the perovskite crystal composite material A1 into the solvent DMF, and ultrasonically stir until completely dissolved to obtain a perovskite composite crystal solution for later use.

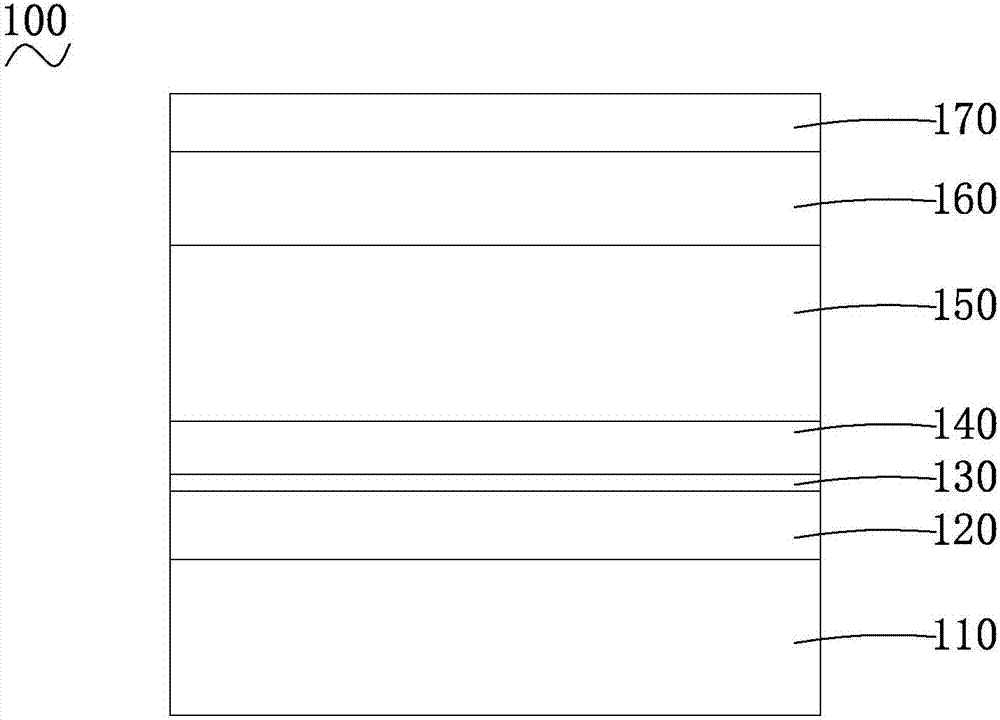

[0091] The fabrication process of perovskite solar cells is as follows:

[0092] A transparent electrode (500nm thick FTO transparent electrode) was evaporated on a clean transparent substrate (2.5mm thick glass substrate).

[0093] Coat the dense layer material dispersion on the transparent electrode, and make a dense electron transport layer (50nm thick ZnO through high temp...

Embodiment 2

[0100] Example 2 is basically the same as Example 1, except that the volume ratio of 1:400 is used instead of 1:800.

[0101] The obtained perovskite solar cell is denoted as D2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com