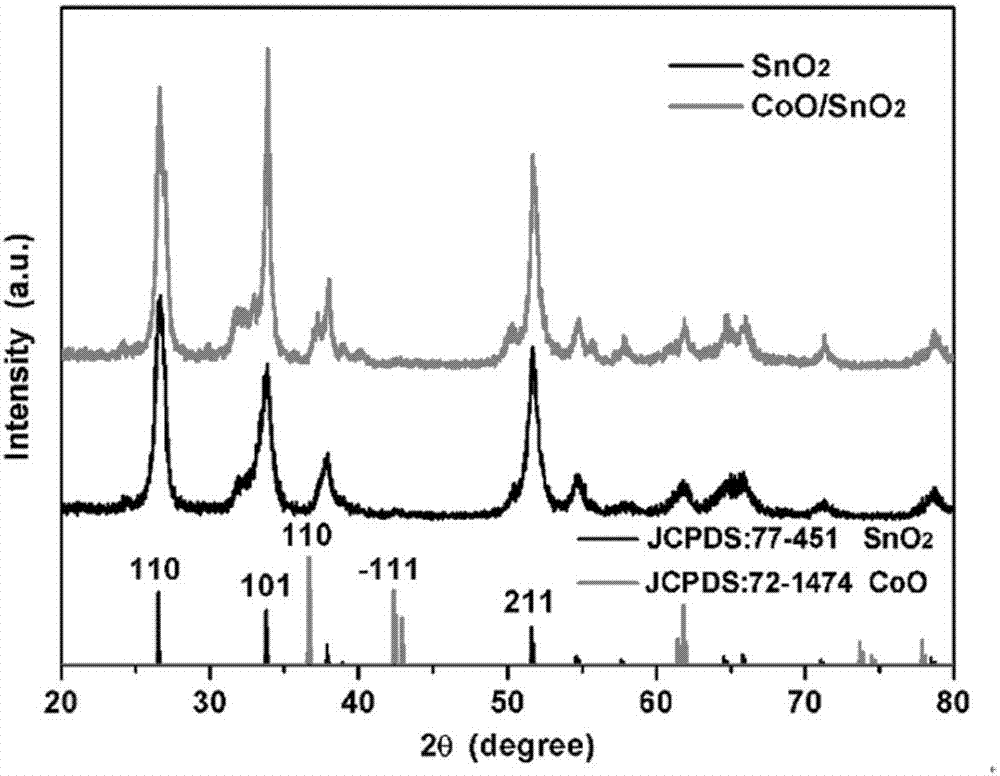

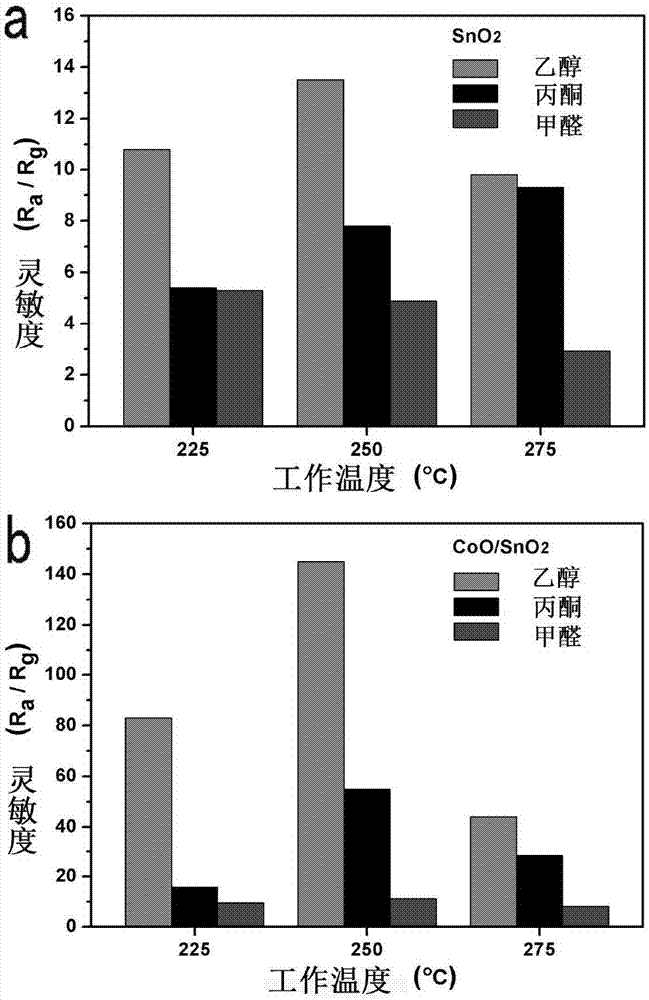

CoO/SnO2 sensitive material and preparation method thereof

A technology of sensitive materials and hydrothermal method, applied in the direction of nanotechnology for materials and surface science, analytical materials, material resistance, etc., can solve the problem of compound semiconductor oxides with only uniform morphology, difficult to control reaction conditions, and few research reports to achieve excellent ethanol sensitivity performance, good ethanol response, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] CoO / SnO 2 Sensitive materials are used to make ethanol gas sensors, the specific method is as follows,

[0055] 1) SnCl 2 2H 2 O (0.9g), Na 3 C 6 h 5 o 7 2H 2 O (2.94g) was dissolved in 15mL deionized water with stirring, then 15mL NaOH (0.12g) aqueous solution was added dropwise and then stirred for 20 minutes to form a homogeneous solution;

[0056] 2) Put the homogeneous solution into a 45mL polytetrafluoroethylene kettle and seal it, put it in an oven at 180°C for 12 hours, and then cool it down to room temperature naturally;

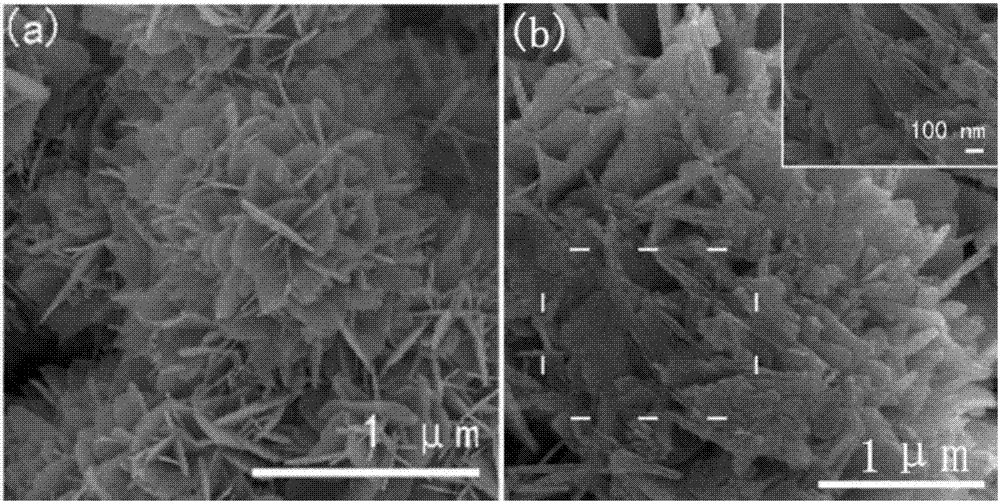

[0057] 3) After collecting the sample, centrifuge it with ethanol and deionized water for 3 to 5 times, then put the sample in a petri dish at 80°C for 12 hours, collect the sample, and calcinate the above sensitive material at 500°C for 2 hours to obtain SnO 2 Sensitive materials with flower-like hierarchical structure;

[0058] 4) Take a certain amount of SnO 2 Put the powder into 10mL of a mixed aqueous solution of ammonia and hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com