On-line detection device for measuring junction temperature of IGBT power module based on saturation voltage drop

A detection device and power module technology, which is applied in the direction of measuring devices, measuring heat, and adopting electrical devices, etc., can solve problems such as unsuitable for fully packaged modules, high price, interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

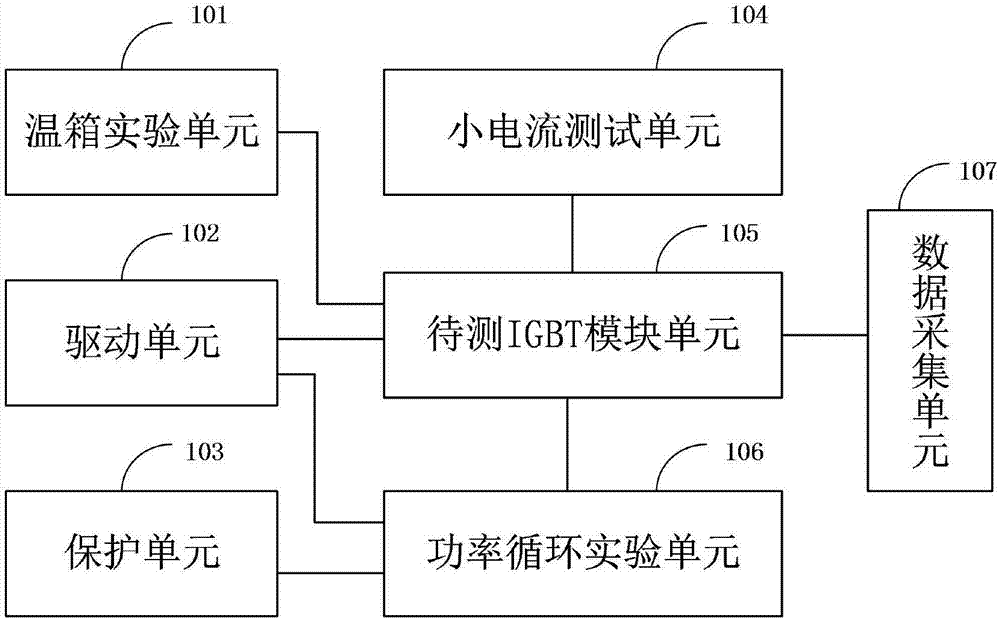

[0026] The specific implementation steps of the present invention will be described in detail below in conjunction with the following examples.

[0027] Such as Figure 7 As shown, it is the implementation flowchart of the IGBT junction temperature detection device provided by the present invention, and the specific implementation steps are divided into: determining V under small current CE with T j The function relationship curve 701 of the IGBT module to be tested; the power cycle experiment 702 with a specific switching time applied to the IGBT module to be tested; the constant small current 703 is applied to the IGBT module to be tested; CE 704; Measure V at the moment of shutdown in the power cycle experiment CE 705.

[0028] Determine V under small current CE with T j When using the thermostat test unit described in 101, put the IGBT module into the thermostat, and set the temperature of the thermostat at 20°C-150°C for 20 minutes until it stabilizes. The gate V o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com