A kind of construction method of bridge expansion joint filling material

A construction method and technology of filling materials, applied in bridges, bridge parts, bridge construction and other directions, can solve the problems of poor tensile and flexural performance, low tensile strength, and grooves on the surface of expansion joints, and achieve good flexural and tensile performance. Impact resistance, improved flexural and tensile properties, and good tensile strain properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The fiber concrete filling material consists of the following components by weight:

[0050] 12 parts of fly ash, 8 parts of quartz sand, 10 parts of cement, 0.0025 parts of water reducing agent, 0.0045 parts of thickener, 0.1 part of polyvinyl alcohol fiber, and 2 parts of water.

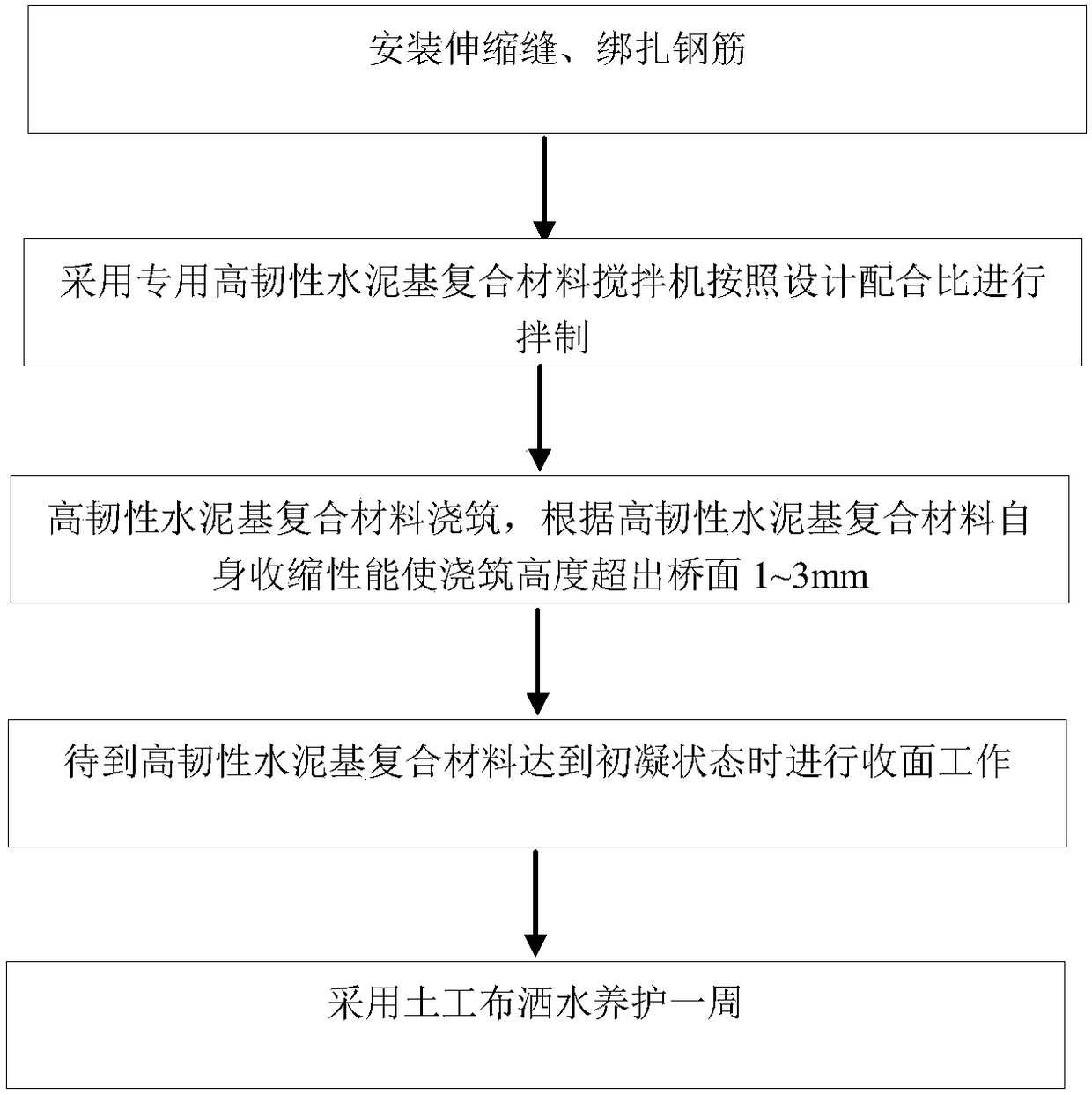

[0051] The preparation method of fiber concrete composite filling material comprises the following steps:

[0052] Before mixing, first add a small amount of water from the discharge port, start the mixer to wet the inner wall of the mixing tank and the stirring teeth, drain the internal moisture, and add quartz sand, cement, thickener, and fly ash into the mixer from the top feeding port , start the driver switch of the mixing tank, and dry mix for 2 minutes; then add the water and water reducer mixture from the feeding port, first turn the outer cylinder switch to the feeding direction, stir for 30 seconds, and turn the inner stirring shaft switch to the feeding direction Rotate, graduall...

Embodiment 2

[0067] The fiber concrete filling material consists of the following components by weight:

[0068] 14 parts of fly ash, 9 parts of quartz sand, 11 parts of cement, 0.002 parts of water reducer, 0.004 parts of thickener, 4 parts of polyvinyl alcohol fiber, and 4 parts of water.

[0069] The preparation method of fiber concrete composite filling material comprises the following steps:

[0070] Before mixing, first add a small amount of water from the discharge port, start the mixer to wet the inner wall of the mixing tank and the stirring teeth, drain the internal moisture, and add quartz sand, cement, thickener, and fly ash into the mixer from the top feeding port , start the driver switch of the mixing tank, and dry mix for 2 minutes; then add the water and water reducer mixture from the feeding port, first turn the outer cylinder switch to the feeding direction, stir for 30 seconds, and turn the inner stirring shaft switch to the feeding direction Rotate, gradually increase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com