Environment-friendly diatom ooze composite material and preparation method thereof

A composite material and diatom mud technology, applied in the field of composite materials for construction, can solve the problems of uneven color, powder removal, peculiar smell, etc., and achieve the effects of simple preparation method and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

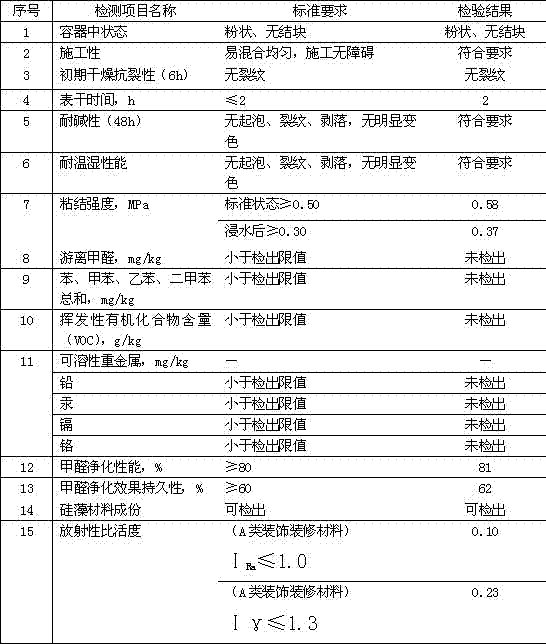

Examples

Embodiment 1

[0028] A new type of environmentally friendly diatom mud composite material and its preparation method. The invention consists of the following raw materials (total mass 100kg): 20% diatomite (600 mesh), 20% quartz powder (200 mesh), heavy Calcium carbonate 27% (800 mesh), talc powder 27% (1250 mesh, flake), redispersible latex powder 5%, hydroxypropyl methylcellulose 0.5% (100,000-120,000 viscosity), wood fiber 0.5% , appropriate amount of inorganic pigments, 0.5% photocatalyst additives (nano-composite titanium dioxide, zinc oxide).

[0029] The diatomaceous earth described in this embodiment is 600 mesh, and the whiteness is 95%.

[0030] The heavy calcium powder described in this embodiment is 800 meshes, the whiteness is 95%, and the calcium carbonate content is greater than 95%.

[0031] The quartz sand described in this embodiment is 200 mesh, SiO 2 The content is 95%, Fe 2 o 3 The content is 0.02%, and the refractoriness is 1750℃.

[0032] The talcum powder descri...

Embodiment 2

[0039] A new type of environmentally friendly diatom mud composite material and its preparation method. The invention consists of the following raw materials (total mass 100kg): 25% diatomite (600 mesh), 15% quartz powder (200 mesh), heavy Calcium carbonate 20% (800 mesh), talc powder 34% (1250 mesh, flake), redispersible latex powder 5%, hydroxypropyl methylcellulose 0.5% (100,000-120,000 viscosity), wood fiber 0.5% , Appropriate amount of inorganic pigments, 1% of photocatalyst additives (nano-composite titanium dioxide, zinc oxide).

[0040] The diatomite of the present invention is 600 mesh, and the whiteness is 95%.

[0041] The heavy calcium powder of the present invention is 800 mesh, the whiteness is 95%, and the calcium carbonate content is greater than 95%.

[0042] The quartz powder of the present invention is 200 mesh, SiO 2 The content is 98%, Fe 2 o 3 The content is 0.02%.

[0043] The talc powder of the present invention is 1250 mesh, the bedding structure ...

Embodiment 3

[0050] A new type of environmentally friendly diatom mud composite material and its preparation method. The invention consists of the following raw materials (total mass 100kg): 30% diatomite (600 mesh), 10% quartz powder (200 mesh), heavy Calcium carbonate 25% (800 mesh), talc powder 29% (1250 mesh, flake), redispersible latex powder 5%, hydroxypropyl methylcellulose 0.5% (100,000-120,000 viscosity), wood fiber 0.5% , appropriate amount of inorganic pigments, 2% photocatalyst additives (nano-composite titanium dioxide, zinc oxide).

[0051] The diatomite of the present invention is 600 mesh, and the whiteness is 90%.

[0052] The heavy calcium powder of the present invention is 800 mesh, the whiteness is 95%, and the calcium carbonate content is greater than 95%.

[0053] The quartz powder of the present invention is 200 mesh, SiO 2 The content is 98%, Fe 2 o 3 The content is 0.02%.

[0054] The talc powder of the present invention is 1250 mesh, the bedding structure is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com