Novel fried-flavor high-calcium minced meat conditioning gel product and production process thereof

A technology for conditioning gels and products, applied in food science and other directions, can solve problems such as a reduction rate of less than 30%, and achieve the effects of increased absorption capacity, enhanced absorption, and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

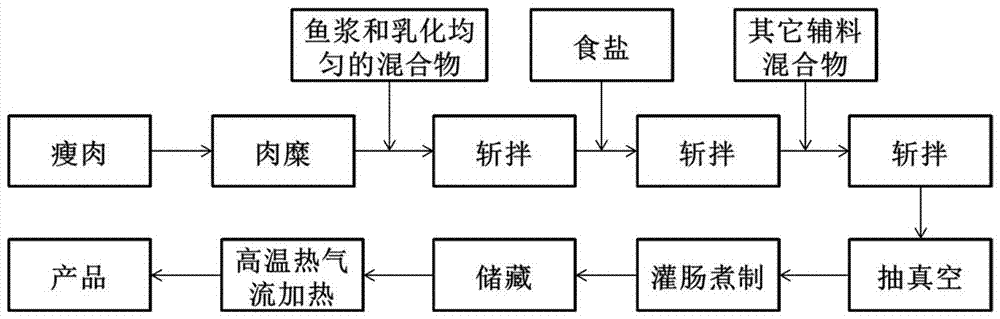

Method used

Image

Examples

Embodiment 1

[0053] (1) Choose fresh lean pork meat, wash it with cold water below 4-10°C, cut it into pieces after cleaning, and drain the surface water of the meat piece;

[0054] (2) Preparation of the original seasoning liquid: replace the seasoning liquid with ice water to obtain the original seasoning liquid.

[0055] (3) Put the pretreated meat pieces in step (1) into a food conditioner, chop and mix for 1 minute under the conditions of temperature control at 4-10°C and rotation speed of 1200-1800r / min to obtain minced meat, add fish paste and The mixture of emulsified fat meat, soybean protein isolate and ice water was chopped and mixed for 1.5 minutes, then salt was added and mixed for 0.5 minutes, then the mixture of original seasoning liquid, potato starch and compound phosphate was added and mixed for 1.5 minutes.

[0056] (4) Pour the minced pork pulp seasoned and chopped evenly in step (3) into the casing, and seal both ends. Heating in a water bath at 90°C for 30-40min, the...

Embodiment 2

[0060] (1) Choose fresh lean pork meat, wash it with cold water below 4-10°C, cut it into pieces after cleaning, and drain the surface water of the meat piece;

[0061] (2) Preparation of the original seasoning liquid: replace the seasoning liquid with ice water to obtain the original seasoning liquid.

[0062] (3) Put the pretreated meat pieces in step (1) into a food conditioner, chop and mix for 1 minute under the conditions of temperature control at 4-10°C and rotation speed of 1200-1800r / min to obtain minced meat, add fish paste and The mixture of emulsified fat meat, soybean protein isolate and ice water was chopped and mixed for 1.5 minutes, then salt was added and mixed for 0.5 minutes, then the mixture of original seasoning liquid, potato starch and compound phosphate was added and mixed for 1.5 minutes.

[0063] (4) Pour the minced pork pulp seasoned and chopped evenly in step (3) into the casing, and seal both ends. Heating in a water bath at 90°C for 30-40min, the...

Embodiment 3

[0069] (1) Choose fresh lean pork meat, wash it with cold water below 4-10°C, cut it into pieces after cleaning, and drain the surface water of the meat piece;

[0070] (2) Preparation of the original seasoning liquid: replace the seasoning liquid with ice water to obtain the original seasoning liquid.

[0071] (3) Put the pretreated meat pieces in step (1) into a food conditioner, chop and mix for 1 minute under the conditions of temperature control at 4-10°C and rotation speed of 1200-1800r / min to obtain minced meat, add fish paste and The mixture of emulsified fat meat, soybean protein isolate and ice water was chopped and mixed for 1.5 minutes, then salt was added and mixed for 0.5 minutes, then the mixture of original seasoning liquid, potato starch and compound phosphate was added and mixed for 1.5 minutes.

[0072] (4) Pour the minced pork pulp seasoned and chopped evenly in step (3) into the casing, and seal both ends. Heating in a water bath at 90°C for 30-40min, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com