Preparation method for nitrogen-doped carbon fiber material

A nitrogen-doped carbon fiber, carbon fiber technology, applied in carbon fiber, fiber processing, textiles and papermaking, etc., can solve the problems of inability to prepare in large quantities, high temperature, harsh process conditions, etc., and achieve low cost, improved lithium storage performance, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Put urea and carbon fiber separately into a hydrothermal reaction kettle with a mass ratio of 1:5. After sealing, conduct a hydrothermal reaction at 180°C for 12 hours. After the reaction, cool to room temperature to obtain the final product nitrogen-doped carbon fiber material .

[0026] Embodiment 1 gained material uses X-ray diffraction to analyze crystal structure, as figure 1 As shown, the results show that the carbon fiber prepared in Example 1 is mainly composed of amorphous carbon.

[0027] Adopt scanning electron microscope to detect the morphology of the nitrogen-doped carbon fiber material that embodiment 1 obtains, as figure 2 As shown, the results show that the morphology of nitrogen-doped carbon fibers prepared in Example 1 is fibrous.

Embodiment 2

[0029] Put the ammonium carbonate and carbon fiber separately into the hydrothermal reaction kettle with a mass ratio of 1:8. After sealing, conduct a hydrothermal reaction at 200°C for 12 hours. After the reaction, cool to room temperature to obtain the final product nitrogen-doped carbon fiber. Material.

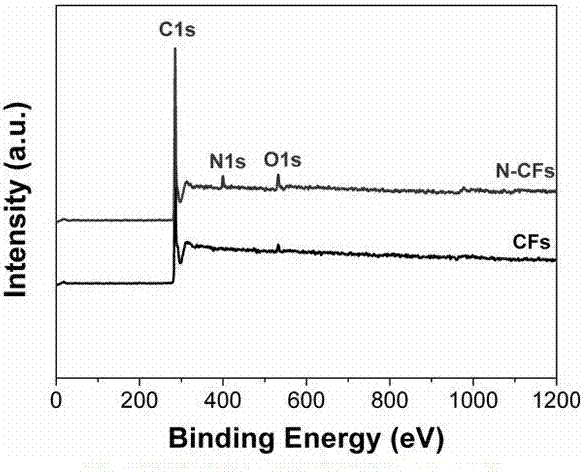

[0030] Embodiment 2 gained material uses energy spectrometer to analyze contained element, and result is as follows image 3 As shown, it is proved that nitrogen element has been doped to carbon fiber.

Embodiment 3

[0032] Put the ammonium carbonate and carbon fiber separately into the hydrothermal reaction kettle with a mass ratio of 1:10. After sealing, conduct a hydrothermal reaction at 180°C for 15 hours. After the reaction, cool to room temperature to obtain the final product nitrogen-doped carbon fiber. Material.

[0033] The morphology of the nitrogen-doped carbon fiber material obtained by electron transmission electron microscope detection embodiment 3, such as Figure 4 As shown, the results show that the morphology of nitrogen-doped carbon fibers prepared in Example 3 is fibrous.

[0034] The material obtained in Example 3 was assembled into a button battery, and the cycle performance of the battery was tested by using the blue electric battery test system. Such as Figure 5 As shown, the results show that the nitrogen-doped carbon fiber material prepared in Example 3 has excellent cycle performance, and after 500 cycles at a current density of 1A / g, the specific capacity sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com