Horizontal expansion device for bridge detection operating vehicle

A horizontal telescopic and bridge inspection technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as complex structure, unreliable telescopic movement, self-slipping of telescopic arms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

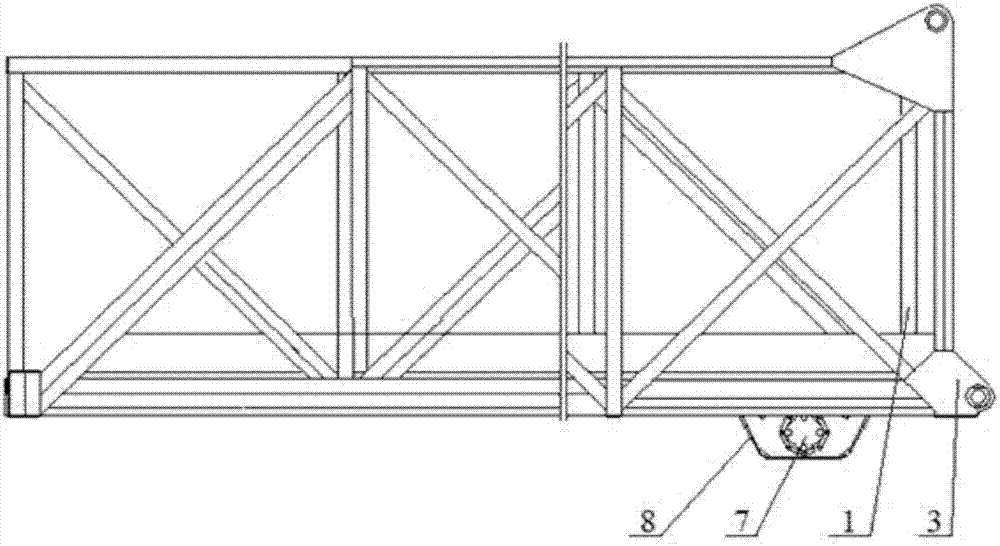

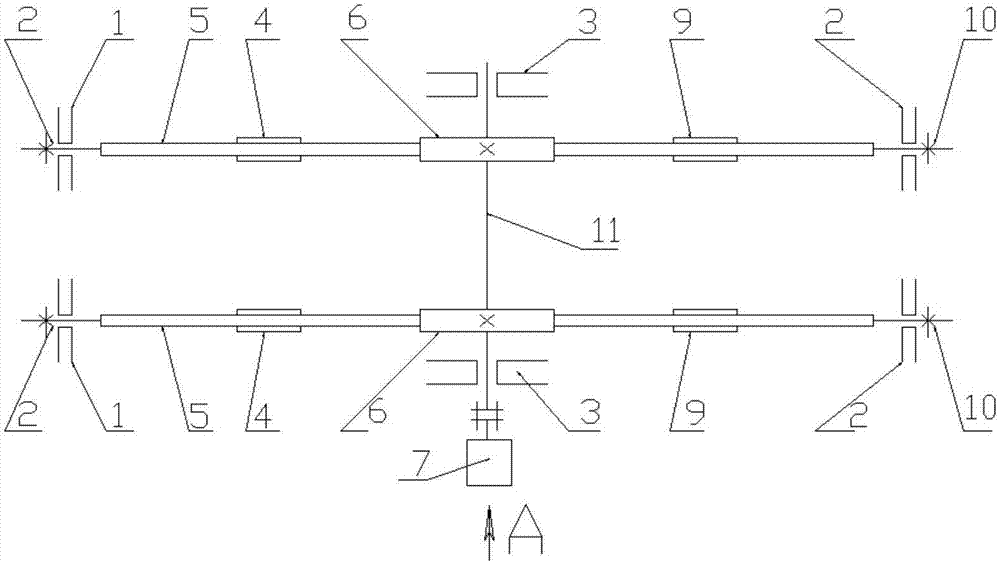

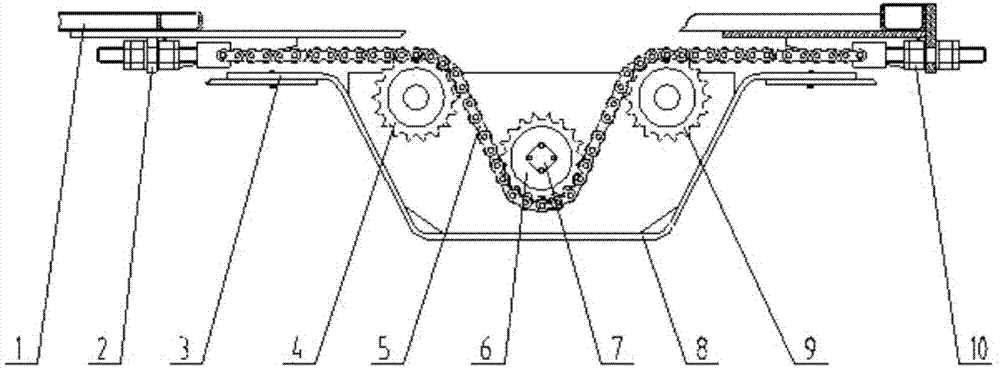

[0009] combine figure 1 , figure 2 , image 3 , the specific embodiment of the present invention is:

[0010] The horizontal telescopic device of a bridge inspection vehicle is mainly composed of a boom assembly, a symmetrically arranged chain transmission device, a chain tensioning device, and a hydraulic motor 7 . The jib assembly includes the basic arm 3 and the telescopic arm 1. The basic arm 3 and the telescopic arm 1 are frame-shaped truss structures welded by section steel. The upper, middle and lower rectangular steel pipes stretch along the basic arm 3, the middle rectangular steel pipe is fixed on the lower part of the front outer surface of the telescopic arm 1, and the upper and lower rectangular steel pipes are respectively fixed on the front side of the basic arm 3 The lower part of the inner surface; the chain transmission device includes a sprocket box 8, a pair of symmetrically arranged drive sprockets 6, a pair of symmetrically arranged I guide sprockets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com