Separate type submersible pressure hull clamp automatic locking device and submersible pressure hull adopting the locking device

An automatic locking, submersible technology, used in transportation and packaging, underwater operation equipment, ships, etc., can solve the problem that the clamp and the pressure hull cannot be in close contact, increase the separation of the pressure hull and enter the water, and deep-sea personal safety. Threats and other issues, to achieve the effect of reducing processing and installation accuracy requirements, simple structure, and beneficial to modular manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

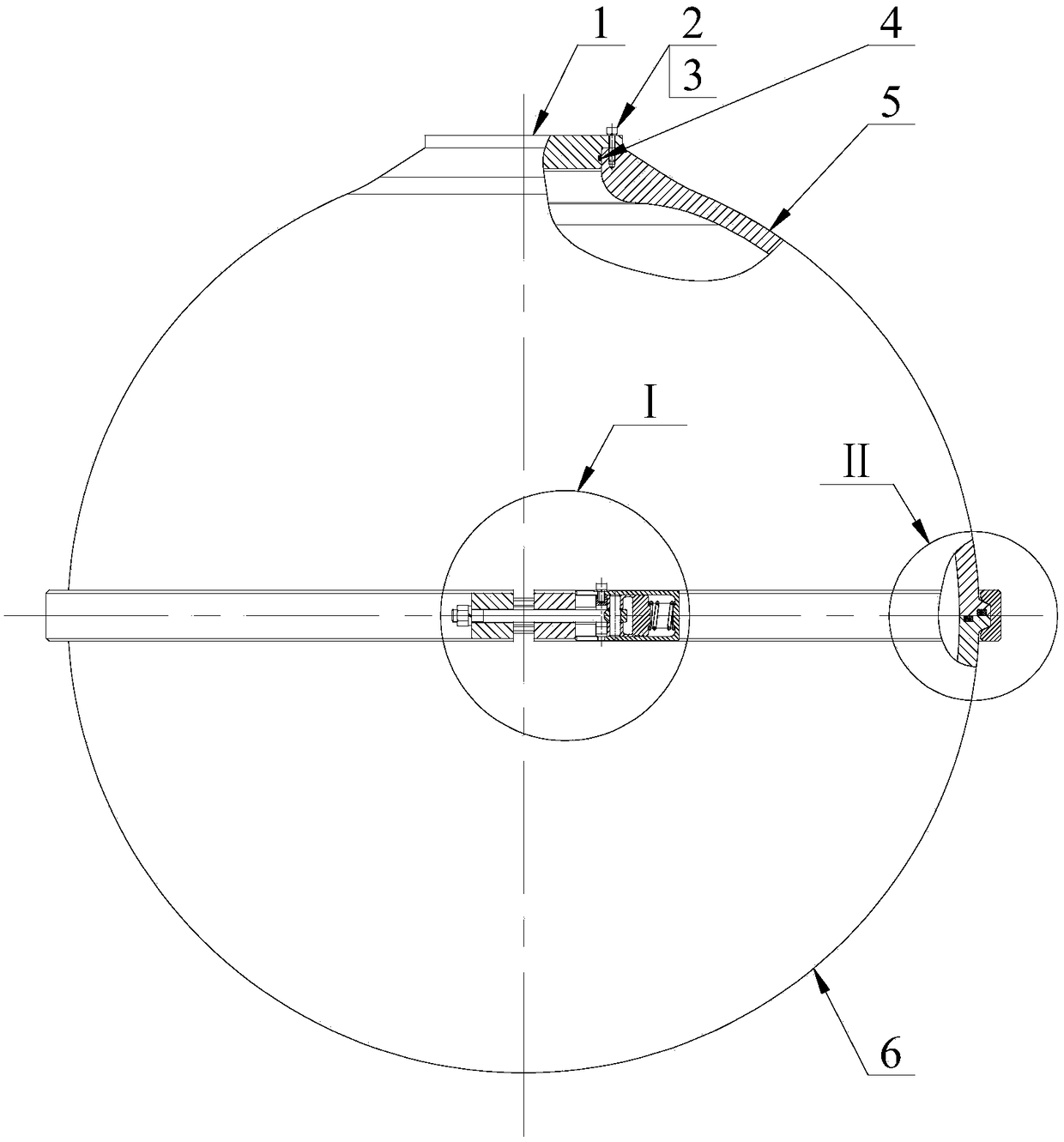

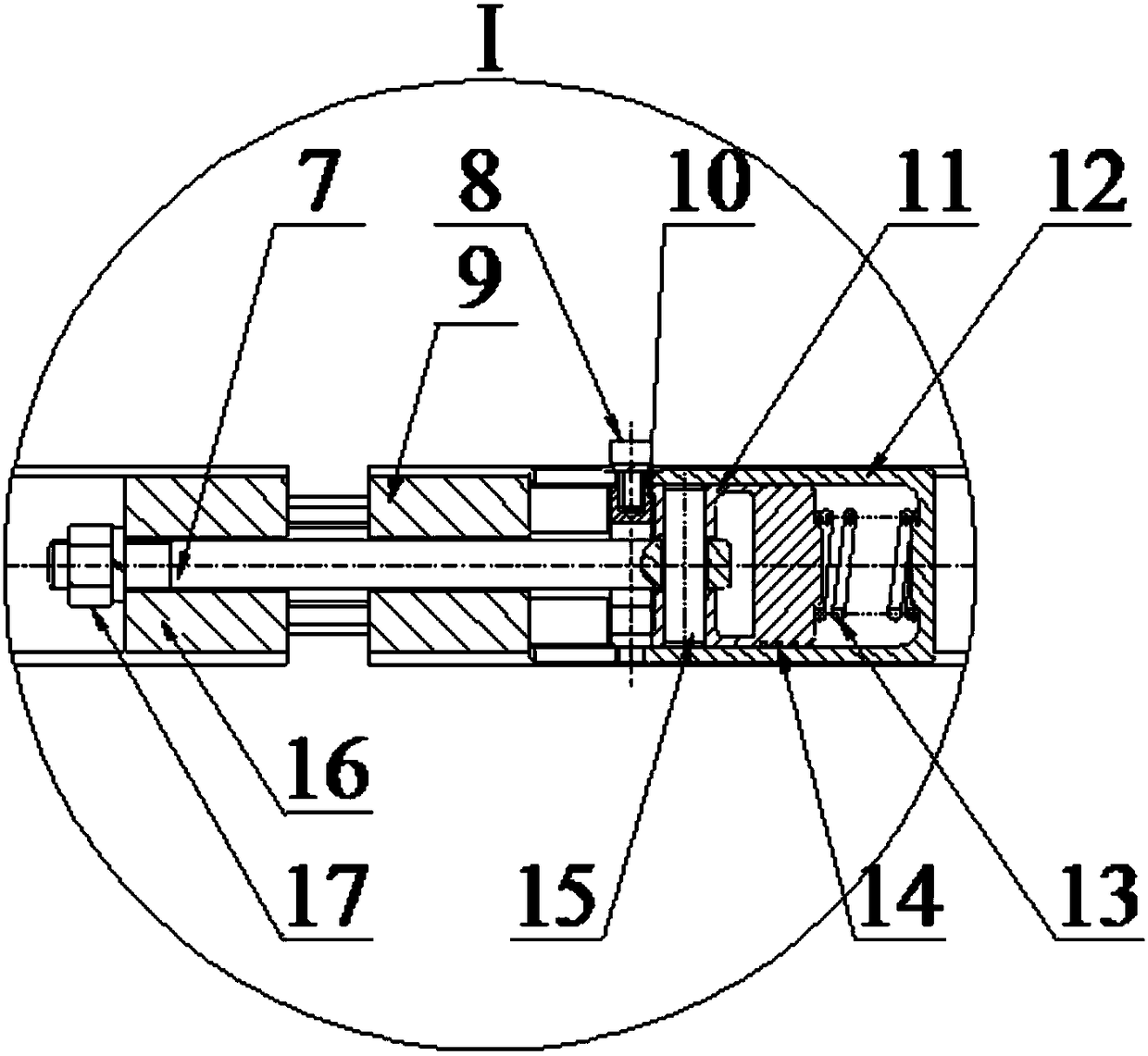

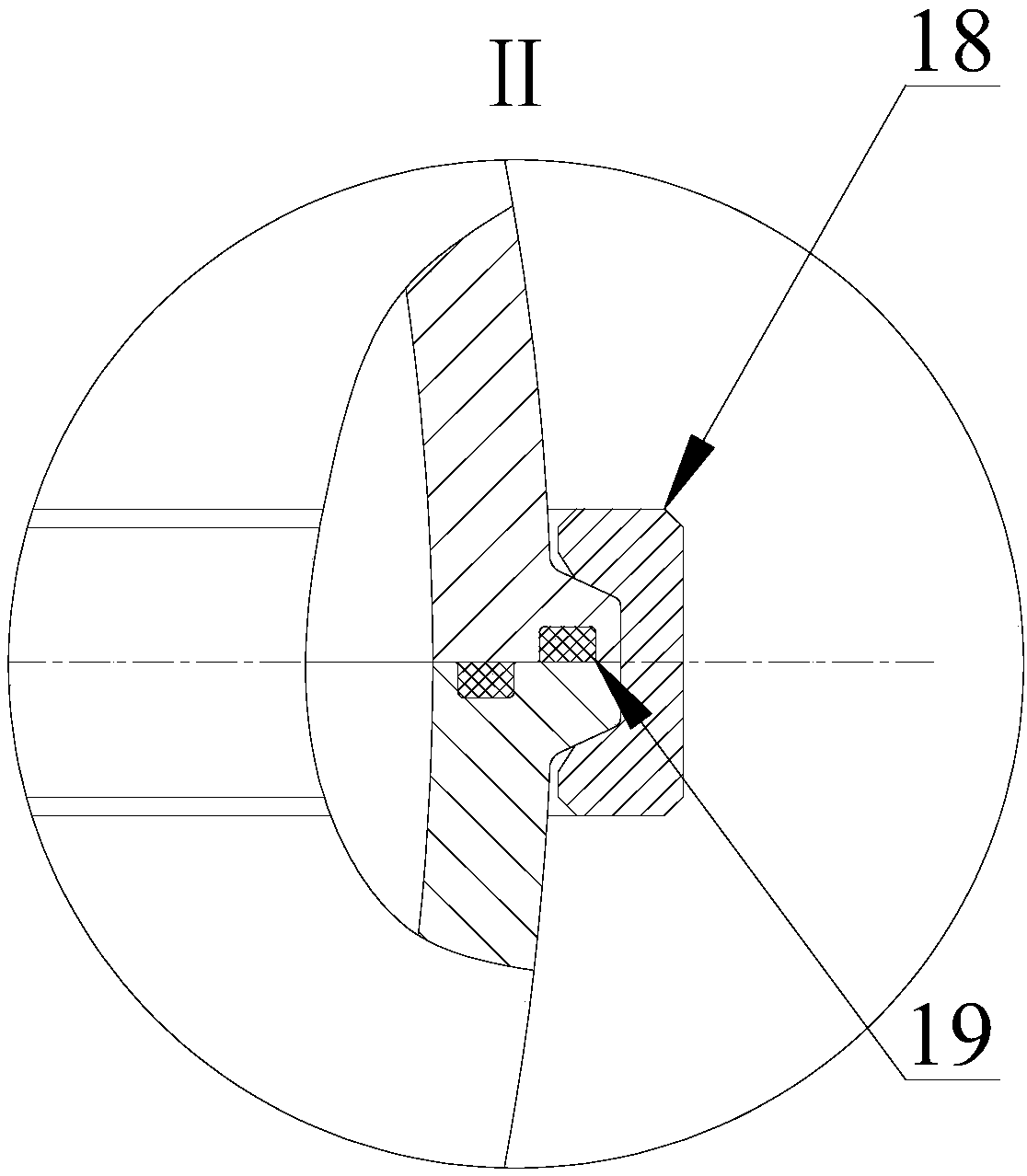

[0035] like Figure 1-6 As shown, a separate automatic locking device for submersible pressure shell clamp 18 includes a mounting block 16 arranged at one end of the clamp 18, and an installation through hole is provided in the mounting block 16 along the length direction of the clamp 18; The other end of the hoop 18 is provided with a threaded boss 9, and the center of the threaded boss 9 is provided with a through hole along the length direction of the hoop 18. The piston cylinder 12 with one end closed and one end open is provided with a connecting thread on the inner wall of the open end, and the piston cylinder 12 is passed through. The thread is connected with the threaded boss 9 on the clamp 18 . Piston cylinder 12 is provided with piston 11, is provided with three sealing rings 14 between piston 11 outer periphery and piston cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com