Composite material of nano zero-valent iron and silver metal cluster loaded on activated carbon and preparation method of composite material

A technology of nano-zero-valent iron and composite materials, which is applied in chemical instruments and methods, other chemical processes, special treatment targets, etc., can solve the problems of inability to use advanced treatment of drinking water, loss of functional metal particles, high cost of wastewater treatment, etc., to achieve Effect of high social and economic value, low ash content and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

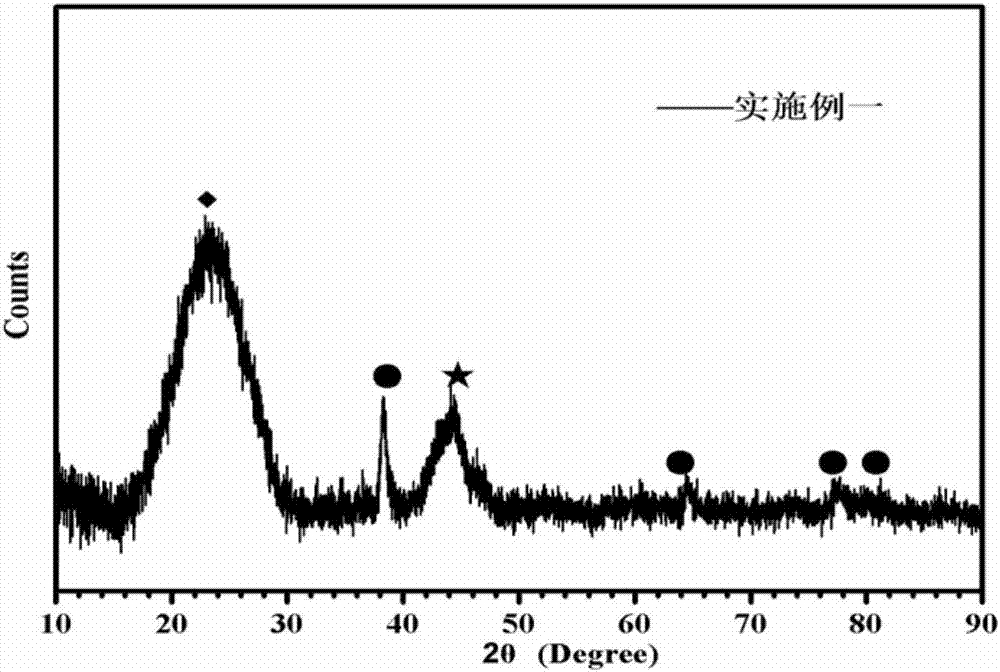

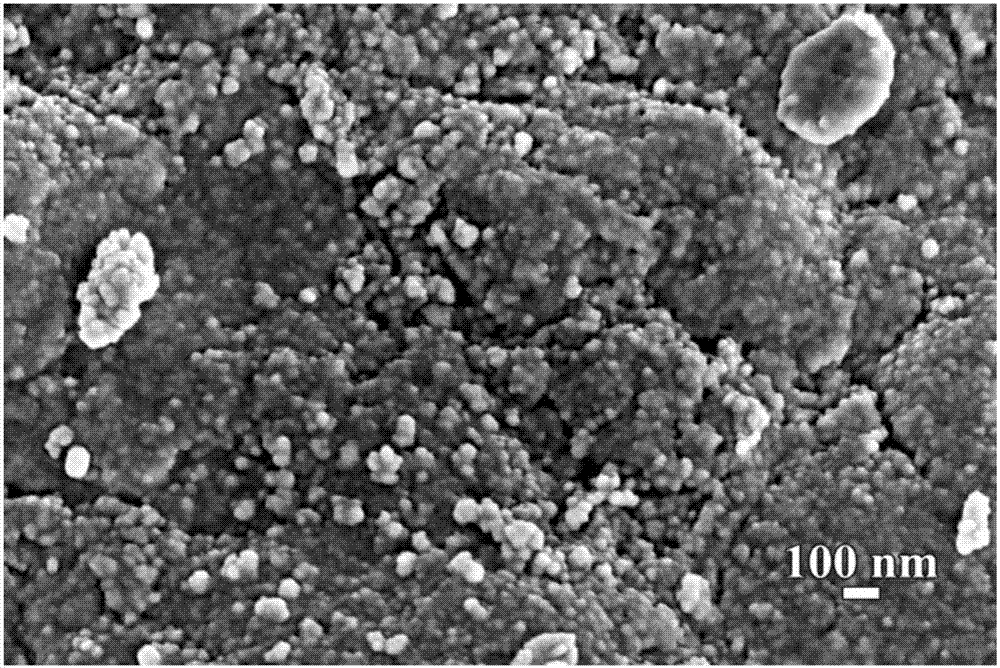

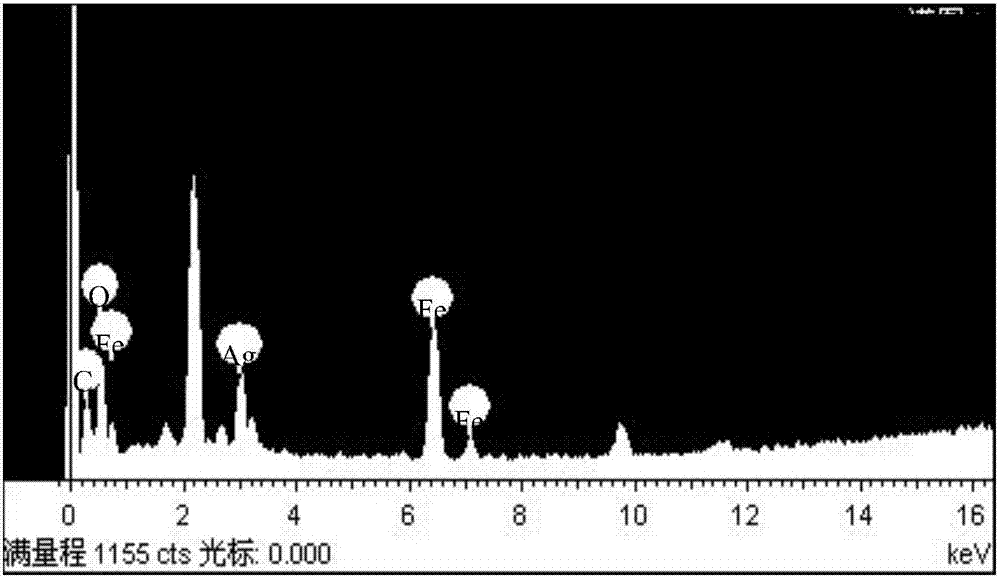

Embodiment 1

[0048] The preparation of the composite material of activated carbon loaded with nanometer zero-valent iron and silver metal clusters comprises the following steps: a) screening the activated carbon of 1.0-1.5 mm, washing and drying with deionized water, adding it to 5% hydrochloric acid and soaking it for 24 hours, Wash with deionized water until the pH remains constant, and then dry; b) Weigh FeSO 2 according to the mass ratio of iron to activated carbon of 1:10 4 ·7H 2 0, adding 100mL volume ratio of ultrapure water and absolute ethanol mixed solvent and 0.2g of polyethylene glycol, the stirrer speed is 350r / min, the reaction time is 30min, room temperature, feed N 2 c) Add 2g of activated carbon to the solution described in step b), stir for 120min, slowly add 100mL of 0.15mol / L NaBH 4 solution, the rotation speed is 450r / min, and N 2 , to be NaBH 4 The solution is added and reacted until no bubbles are generated. The reaction equation is: Fe 2+ (aq)+2BH 4 - (aq)+6H ...

Embodiment 2

[0054] The preparation of the composite material of activated carbon loaded with nanometer zero-valent iron and silver metal clusters comprises the following steps: a) screening the activated carbon of 1.0-1.5 mm, washing and drying with deionized water, adding it to 5% hydrochloric acid and soaking it for 24 hours, Wash with deionized water until the pH remains constant, and then dry; b) Weigh FeSO 2 according to the mass ratio of iron to activated carbon of 1:10 4 ·7H 2 0, adding 100mL volume ratio of ultrapure water and absolute ethanol mixed solvent and 0.2g of polyethylene glycol, the stirrer speed is 350r / min, the reaction time is 120min, room temperature, feed N 2 c) Add 2g of activated carbon to the solution described in step b), stir for 120min, slowly add 100mL of 0.15mol / L NaBH 4 solution, the rotation speed is 450r / min, and N 2 , to be NaBH 4 The solution is added and reacted until no bubbles are generated. The reaction equation is: Fe 2+ (aq)+2BH 4 - (aq)+6H...

Embodiment 3

[0060] The preparation of the composite material of activated carbon loaded with nanometer zero-valent iron and silver metal clusters comprises the following steps: a) screening the activated carbon of 1.0-1.5 mm, washing and drying with deionized water, adding it to 5% hydrochloric acid and soaking it for 24 hours, Wash with deionized water until the pH remains constant, and then dry; b) Weigh the FeSO 2 according to the mass ratio of iron to activated carbon of 1:5 4 ·7H 2 0, adding 100mL volume ratio of ultrapure water and absolute ethanol mixed solvent and 0.2g of polyethylene glycol, the stirrer speed is 350r / min, the reaction time is 120min, room temperature, feed N 2 c) Add 2g of activated carbon to the solution described in step b), stir for 120min, slowly add 100mL of 0.15mol / L NaBH 4 solution, the rotation speed is 450r / min, and N 2 , to be NaBH 4 The solution is added and reacted until no bubbles are generated. The reaction equation is: Fe 2+ (aq)+2BH 4 - (aq)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com