Device and method for performing ozone step-by-step oxidative absorption and desulfurization and denitration for industrial flue gas

A technology of ozone oxidation and step-by-step oxidation, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of high ozone consumption and high process cost, achieve simple process and operation, reduce ozone consumption, and improve ozone utilization efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

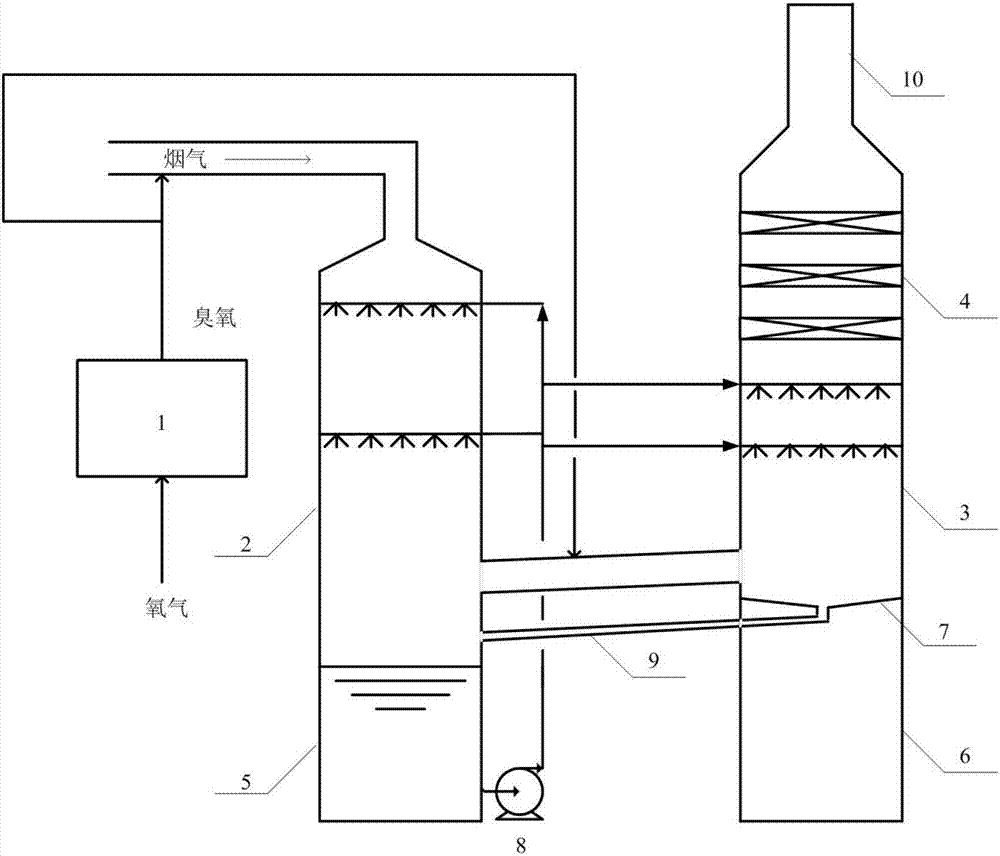

[0064] Such as figure 1 As shown, this embodiment provides a device for simultaneous desulfurization and denitrification of industrial flue gas ozone step-by-step oxidation absorption, the device includes a flue gas absorption system and an ozone generator 1; the flue gas absorption system includes a first-stage absorption tower 2 and the second stage absorption tower 3. The top of the first-stage absorption tower 1 is provided with a flue gas inlet connected to the flue gas pipeline, and the middle part of the first-stage absorption tower 1 is provided with a flue gas outlet, between the flue gas inlet and the flue gas outlet of the first-stage absorption tower 1 There are 2 spray layers, the top of the second-stage absorption tower 2 is provided with a chimney 10, the middle part of the second-stage absorption tower 2 is provided with a flue gas inlet, and the chimney 10 and the flue gas inlet of the second-stage absorption tower 2 are connected by a Down to be provided wit...

Embodiment 2

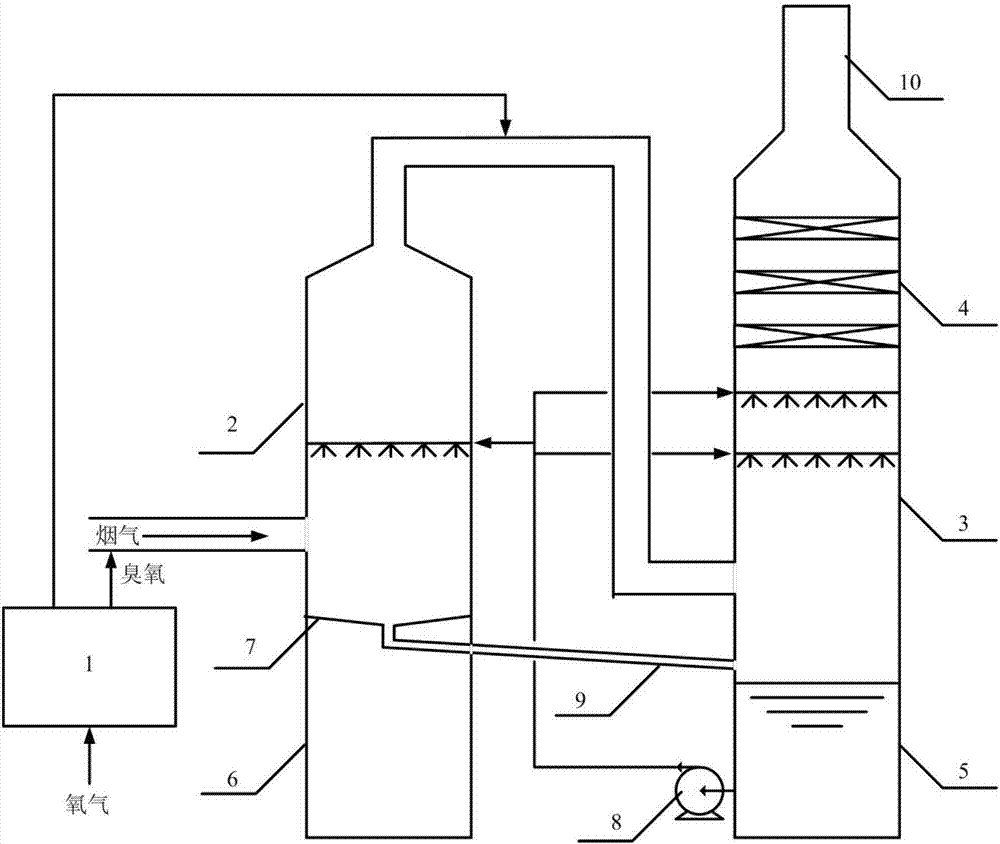

[0075] Such as figure 2 As shown, this embodiment provides a device for simultaneous desulfurization and denitrification of industrial flue gas ozone step-by-step oxidation absorption, the device includes a flue gas absorption system and an ozone generator 1; the flue gas absorption system includes a first-stage absorption tower 2 and the second stage absorption tower 3. The middle part of the first stage absorption tower 1 is provided with a flue gas inlet connected to the flue gas pipeline, and the top of the first stage absorption tower 1 is provided with a flue gas outlet, between the flue gas inlet and the flue gas outlet of the first stage absorption tower 1 There is a spray layer, the top of the second-stage absorption tower 2 is provided with a chimney 10, the middle part of the second-stage absorption tower 2 is provided with a flue gas inlet, and the chimney 10 and the flue gas inlet of the second-stage absorption tower 2 are connected by a Down to be provided with...

Embodiment 3

[0086] This embodiment provides a device for step-by-step oxidation and absorption of industrial flue gas ozone and simultaneous desulfurization and denitrification. The device refers to the device described in Embodiment 1, the difference is that two spray layers are set in the first-stage absorption tower 1, and the second One spray layer is set in the secondary absorption tower 2 .

[0087] The device is used to carry out step-by-step oxidation and absorption of industrial flue gas ozone while desulfurization and denitrification. The method is aimed at the flue gas discharged from an industrial boiler, and the flue gas flow rate: 10000Nm 3 / h, temperature 120℃~140℃, SO 2 Concentration 1000mg / Nm 3 , NO x Concentration 300mg / Nm 3 . The total amount of ozone used in the two-stage oxidation reaction in the process is 1.88kg / h, which is different from the NO in the flue gas x The molar ratio is 0.6.

[0088] The specific method is with reference to the method in Example 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com