Wire crimping repair device and method of substation

A wire crimping and substation technology, applied in the direction of connecting/terminating cable equipment, etc., can solve the problems of low automation, low work efficiency, high labor intensity, etc., achieve high automation, reduce work intensity, and high mechanization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following descriptions of various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be implemented. The terms of direction and position mentioned in the present invention, such as "up", "down", "front", "back", "left", "right", "inside", "outside", "top", "bottom" ", "side", etc., are only referring to the direction or position of the drawings. Therefore, the terms used in direction and position are used to explain and understand the present invention, but not to limit the protection scope of the present invention.

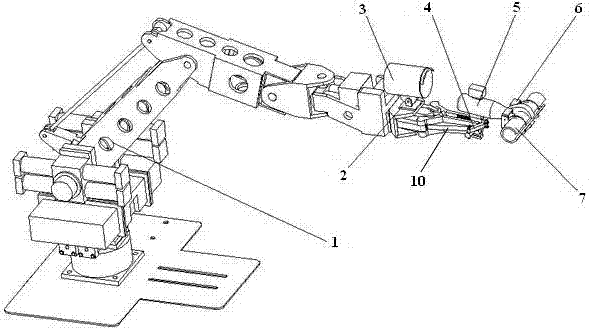

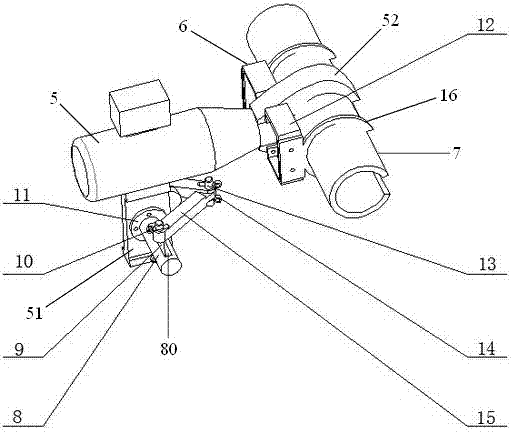

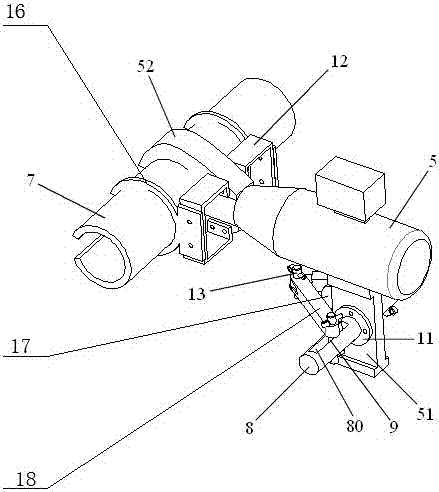

[0028] Please also refer to Figure 1-Figure 3 As shown, Embodiment 1 of the present invention provides a substation wire crimping repair device, including:

[0029] Wire repair pipe 7, used for repairing the wire to be repaired;

[0030] Hydraulic crimping pliers 5, including a handle 51 provided with a crimping switch 17, and a crimping portion 52 for applying hydraulic pressure to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com