A kind of high temperature resistant multi-layer diaphragm composite lithium-ion battery diaphragm and preparation method thereof

A lithium-ion battery and diaphragm composite technology, which is applied to battery pack components, circuits, electrical components, etc., can solve the problems of poor resistance to lithium dendrite penetration and achieve low cost, simple operation, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

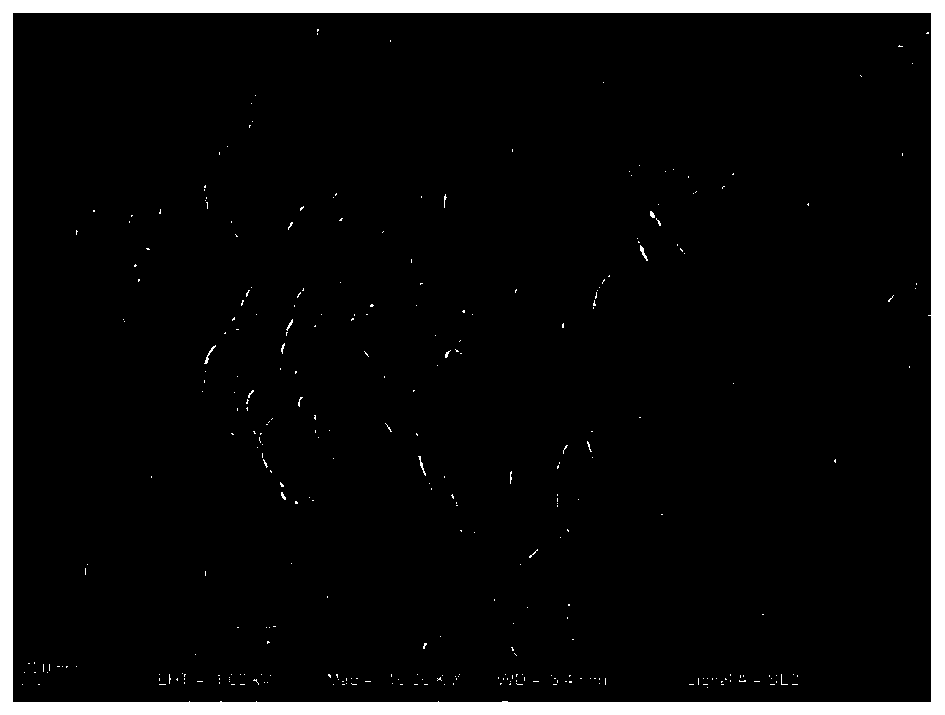

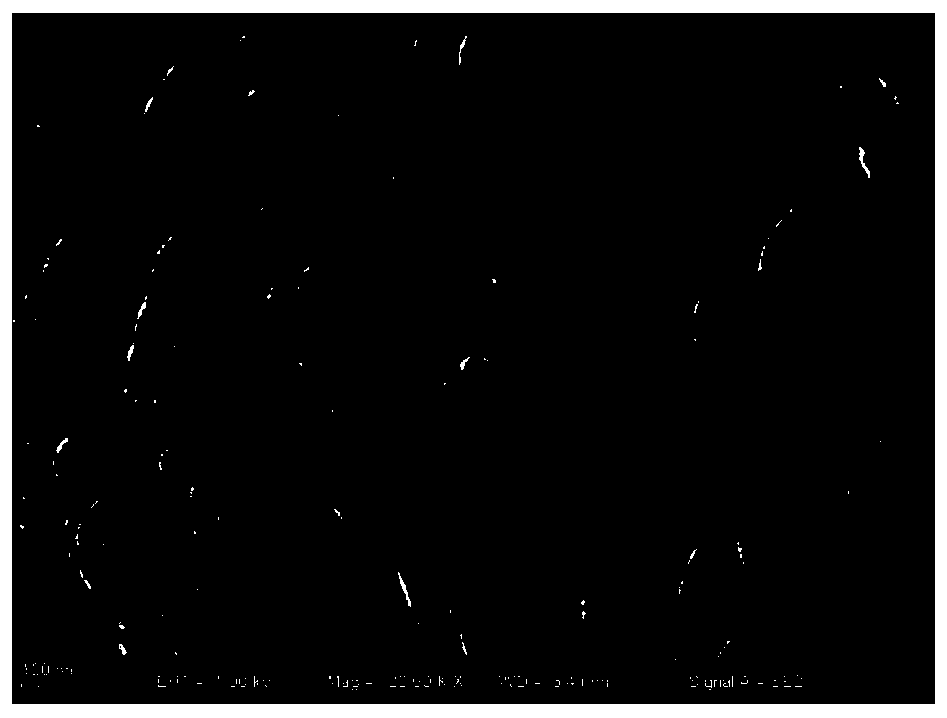

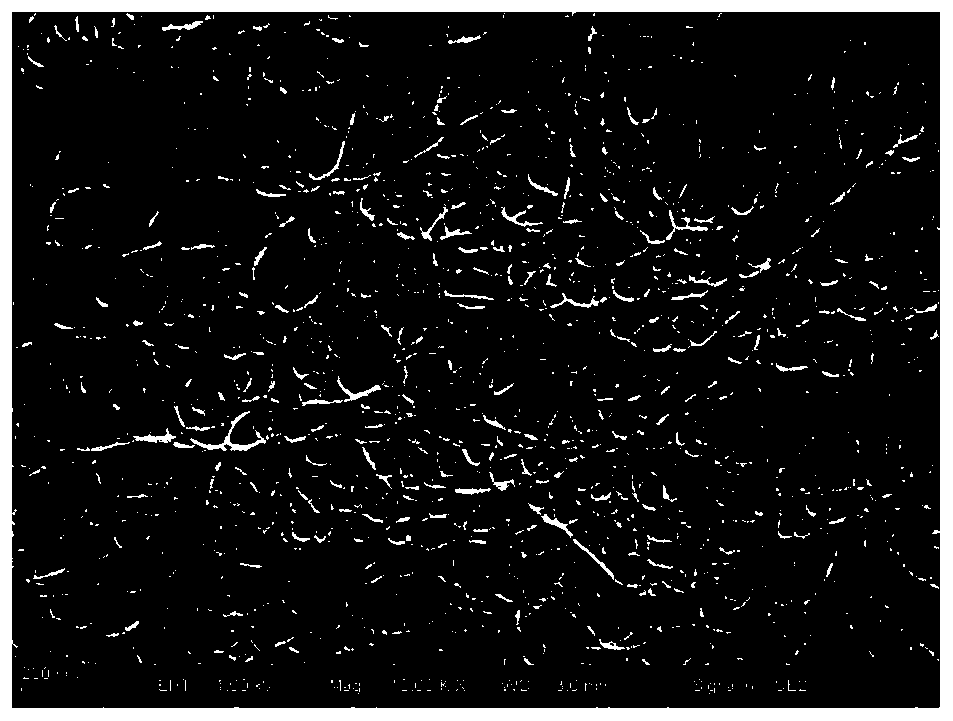

Image

Examples

Embodiment 1

[0054] Two 9μm wet-process PE separators are selected, and Al is used between the two wet-process PE separators. 2 o 3 Ceramic coating slurry is composited into a structure of PE separator-Al 2 o 3 Composite lithium-ion battery separator with ceramic coating-PE separator. where Al 2 o 3 The thickness of the ceramic coating is 2 μm, and the thickness of the prepared composite lithium-ion battery diaphragm is 20 μm.

[0055] The high temperature-resistant multi-layer diaphragm composite lithium-ion battery diaphragm of the present invention can be prepared by a traditional process, and a more optimal choice is to prepare it by the method of the present invention as follows:

[0056] A. Preparation of coating slurry: take the following raw materials by mass percentage, Al 2 o 3 Ceramic slurry 20%, adhesive 3%, dispersant 0.2%, gelling agent 0.2%, plasticizer 0.05%, antiaging agent 0.05%, crosslinking agent 0.05%, thickener 0.1%, photoinitiator 0.3%, the balance is deioniz...

Embodiment 2

[0063] A 12μm wet-process PE separator and a 6um PET non-woven fabric are selected, and the wet-process PE separator and PET non-woven fabric are combined with PVDF coating slurry to form a composite lithium-ion battery separator with a structure of PE separator-PVDF coating-PET non-woven fabric . The thickness of the PVDF coating is 2 μm, and the thickness of the prepared composite lithium-ion battery separator is 20 μm.

[0064] The high temperature-resistant multi-layer diaphragm composite lithium-ion battery diaphragm of the present invention can be prepared by a traditional process, and a more optimal choice is to prepare it by the method of the present invention as follows:

[0065] A. Preparation of coating slurry: Take the following raw materials according to mass percentage, PVDF slurry 25%, adhesive 4%, dispersant 0.3%, gelling agent 0.3%, plasticizer 0.1%, anti-aging agent 0.08 %, 0.1% of crosslinking agent, 0.2% of thickener, 0.5% of photoinitiator, and deionized ...

Embodiment 3

[0071] A 9μm wet-process PE diaphragm and a 6um PMIA (meta-aromatic polyamide) diaphragm are selected, and the wet-process PE diaphragm and PMIA diaphragm are compounded with PTFE (polytetrafluoroethylene) coating slurry to form a PE diaphragm-PTFE coating - Composite Li-ion battery separator with PMIA separator. The thickness of the PTFE coating is 3 μm, and the thickness of the prepared composite lithium-ion battery separator is 18 μm.

[0072] The high temperature-resistant multi-layer diaphragm composite lithium-ion battery diaphragm of the present invention can be prepared by a traditional process, and a more optimal choice is to prepare it by the method of the present invention as follows:

[0073] A. Preparation of coating slurry: Take the following raw materials according to mass percentage, PTFE slurry 30%, adhesive 5%, dispersant 0.4%, gelling agent 0.5%, plasticizer 0.08%, anti-aging agent 0.1 %, 0.07% of crosslinking agent, 0.3% of thickener, 0.7% of photoinitiato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com