Manufacturing method of mirror reflection net dot and diffuser plate

A technology of specular reflection and manufacturing method, which is applied in the field of backlight expansion board, can solve problems such as difficulty in large-scale production, influence of machine size, and easy drop-off of dots, etc., to reduce the number of LEDs, good firmness, and convenient and fast processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

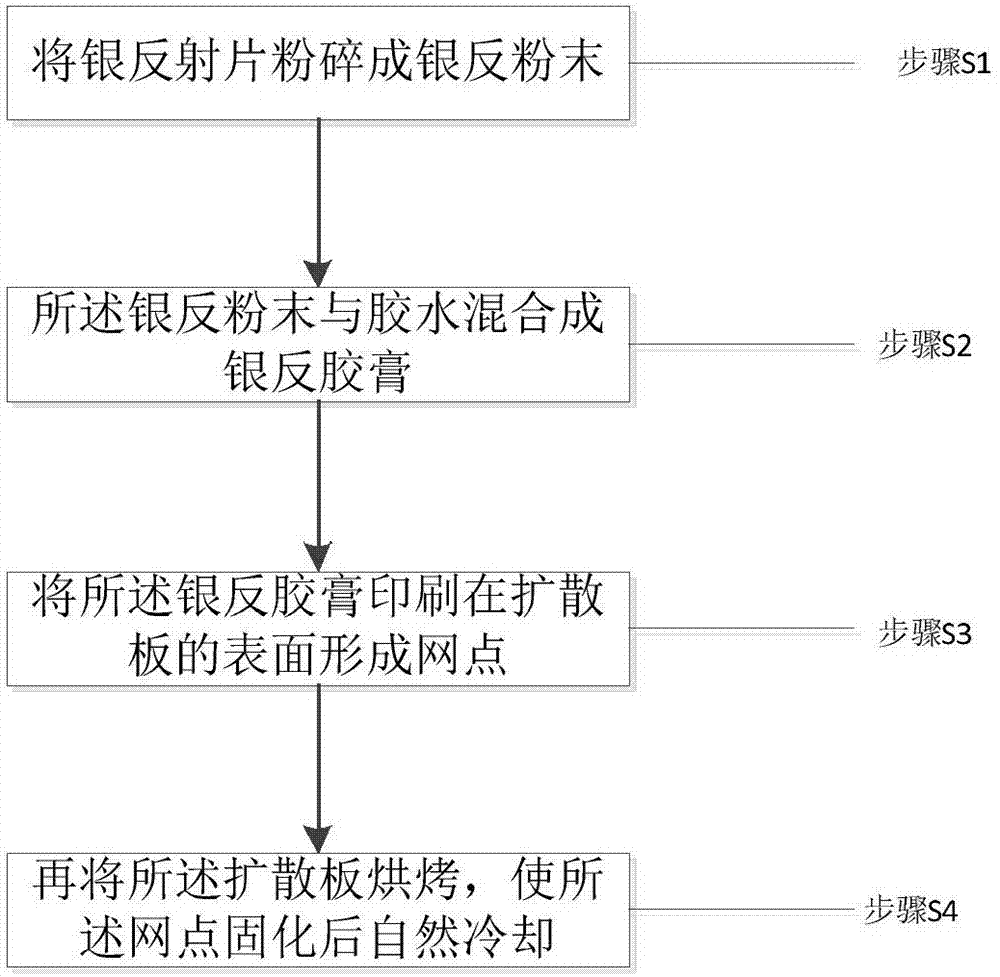

[0024] Such as figure 1 As shown, the figure schematically shows the manufacturing method of the specular reflection dots, the manufacturing method includes step S1: crushing the silver reflective sheet into silver reflective powder; step S2: mixing the silver reflective powder with glue to form silver reflective Adhesive paste; step S3: printing the silver reverse adhesive paste on the surface of the diffuser plate to form dots; step S4: baking the diffuser plate, allowing the dots to solidify and cooling naturally.

[0025] It should be noted that, in the present invention, specular reflection is also called silver reflection, that is, specular reflection dots are also called silver reflection dots, and specular reflection sheets are also called silver reflection sheets.

[0026] It should be noted that, in the present invention, the silver reverse paste is printed to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com