Control system and method for cooling high temperature solid bulk material in moving bed

A high-temperature solids, control system technology, applied in furnace control devices, improving energy efficiency, improving process efficiency, etc., can solve problems such as damage to equipment, deterioration of working environment, corrosion of buildings, etc., and achieve the effect of increasing moderation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

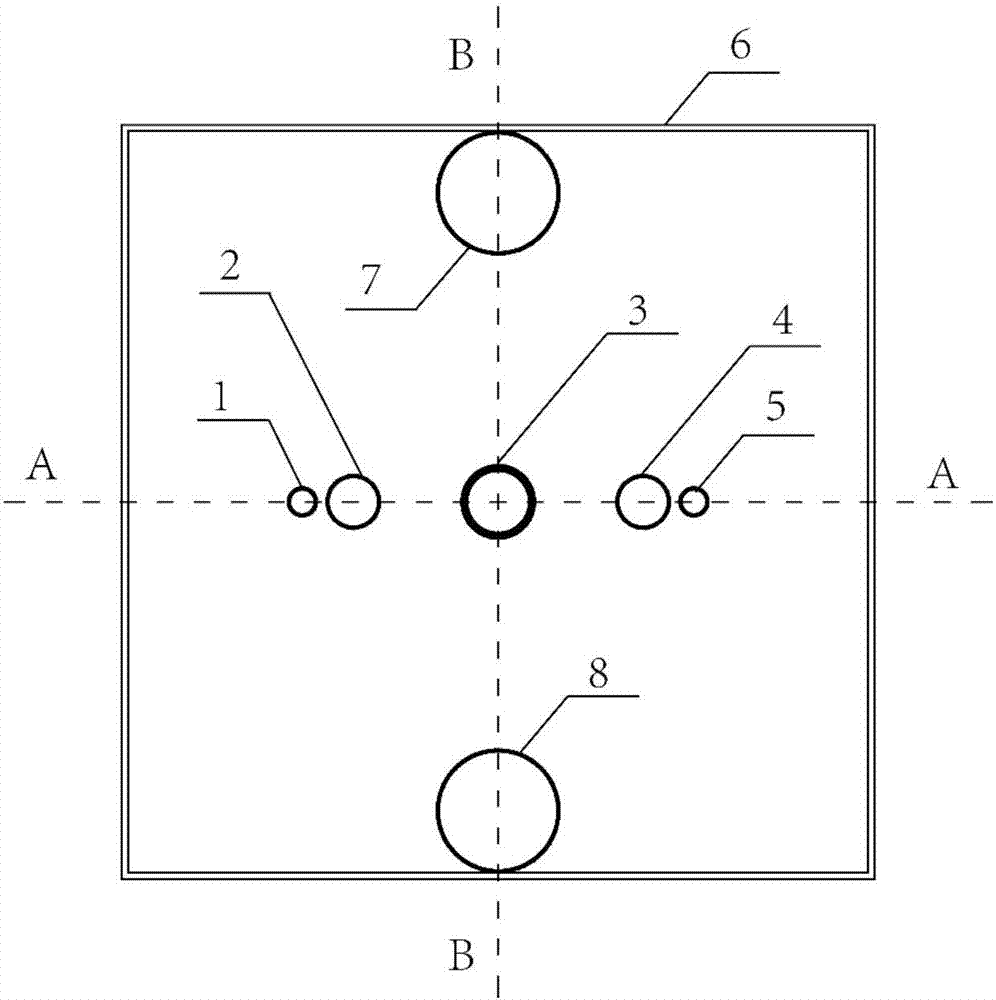

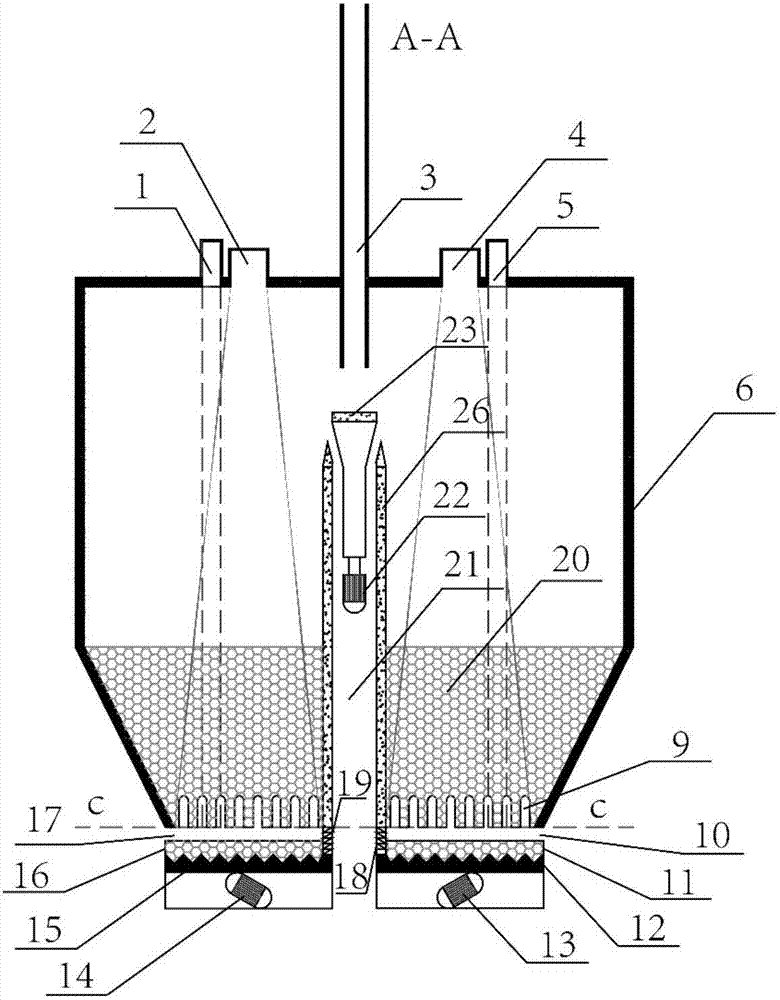

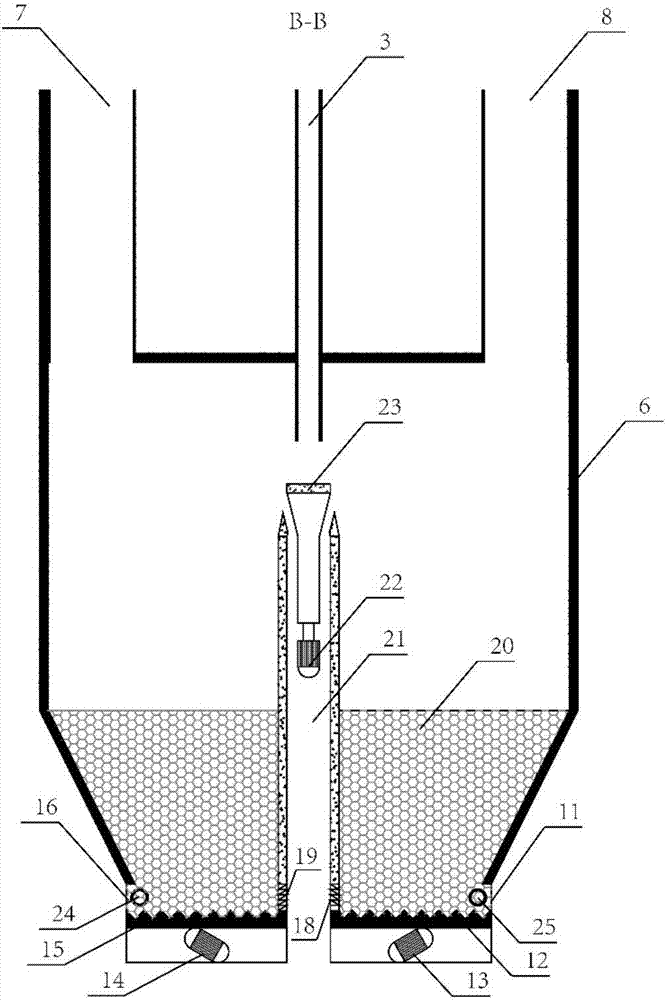

[0036] see Figure 1 to Figure 5 As shown, the present invention relates to the technical field of blast furnace slag waste heat recovery, in particular to a control system and method for cooling high-temperature solid bulk material in a moving bed.

[0037] see Figure 1 to Figure 5 As shown, a control system for cooling high-temperature solid bulk materials in a moving bed includes a granulation bin, a slag falling pipe 3 and a turntable 23 . The slag discharge port of the slag discharge pipe 3 extends into the granulation chamber from the center of the top of the granulation chamber;

[0038] The turntable 23 is connected with a rotor rotating motor 22; the periphery of the rotating shaft of the rotor rotating motor 22 is provided with an edge air duct wall 26; A radar level gauge 2 , a second radar level gauge 4 and a second infrared thermometer 5 . The top of the water wall 6 is also provided with a first air outlet 7 and a second air outlet 8 .

[0039] The bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com