Hollow hidden beam plate structure formed by net pieces and supporting rebar cast-in-place concrete and process

A technology for supporting steel bars and concrete, applied in the direction of floors, building components, building structures, etc., can solve the problems of public environment pollution, increase construction procedures, increase construction difficulty, etc., to improve construction efficiency, reduce construction procedures and construction difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the drawings:

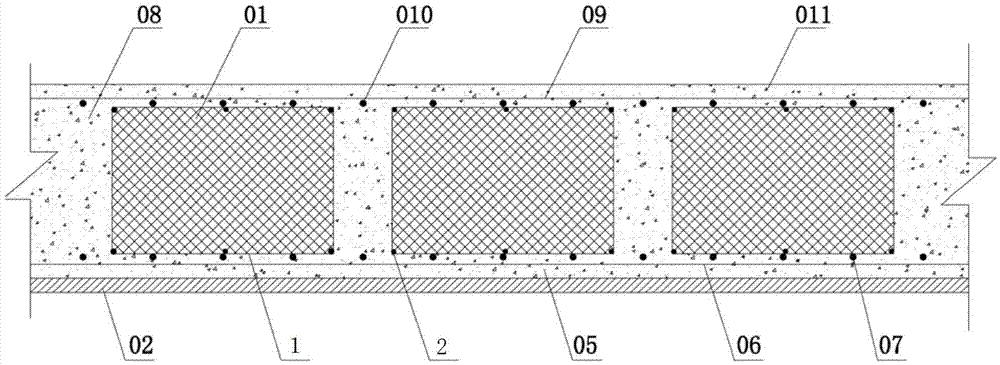

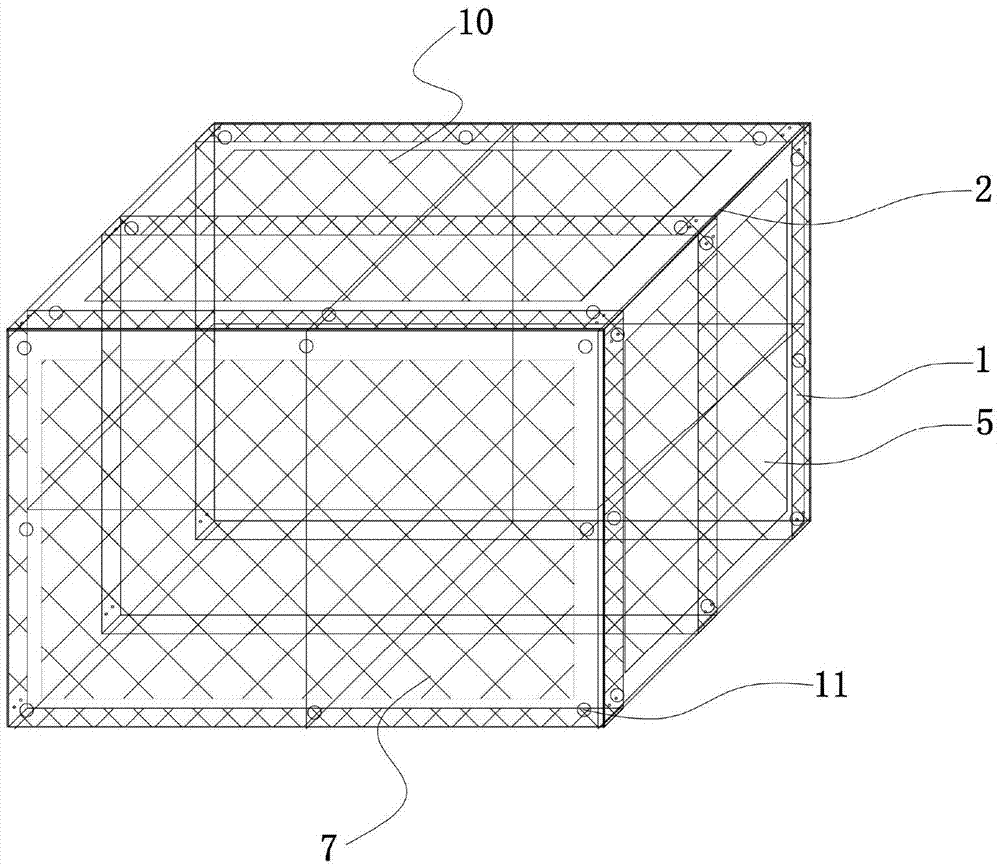

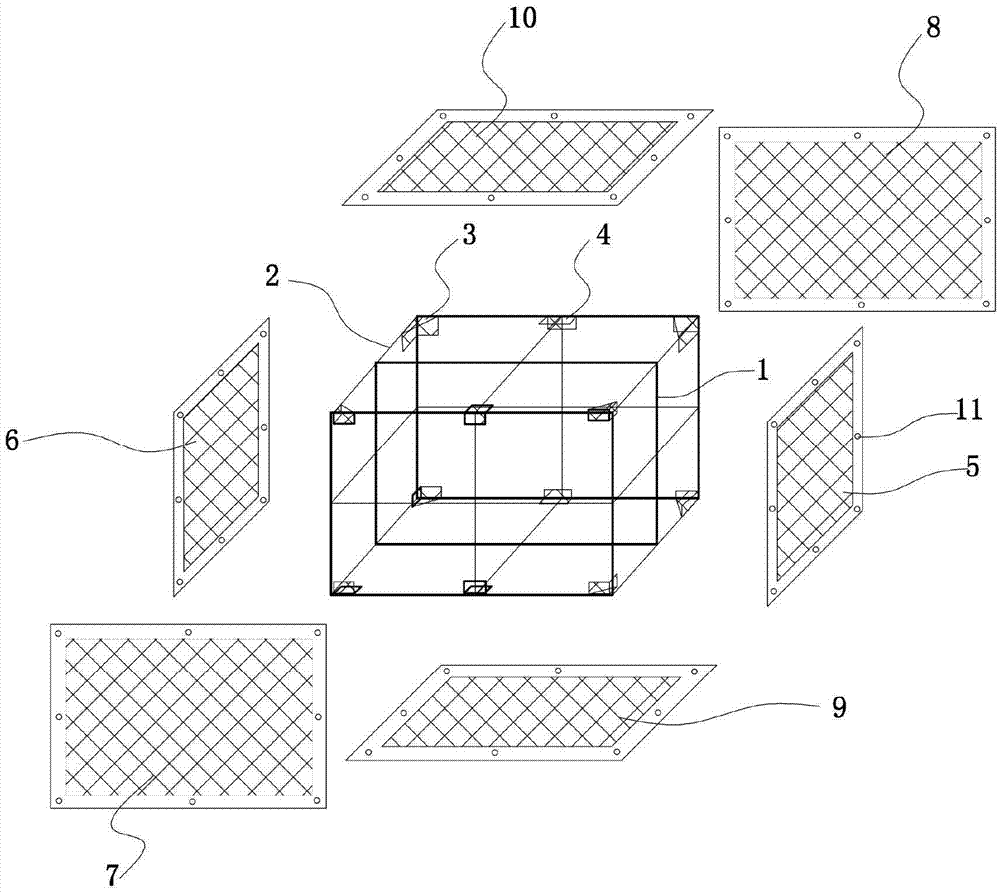

[0031] Such as Figure 1 to Figure 4 As shown, the technical solution adopted by the present invention is as follows: a mesh and supporting steel cast-in-situ concrete form a hollow concealed beam slab structure, which is characterized in that it includes a cage 01, a reinforced mesh body and a concrete filling body, wherein the reinforced mesh The body includes an upper mesh cloth body and a lower mesh cloth body spaced up and down. At least two net cages 01 are evenly spaced between the upper net cloth body and the lower net cloth body. The concrete filling body fills the outer space of the net cage 01 The upper mesh fabric body and the lower mesh fabric body extend outside. The concrete filling body is supported and shaped by the supporting template 02. The concrete filling body is filled from bottom to top, and the air mixed with the concrete filling body is removed from the cage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com