Preparation method of ternary carbide nanobelt

A ternary carbide and nanobelt technology, applied in the field of nanomaterials, can solve the problems of low bonding performance and friction performance, high equipment requirements, long cycle time, etc., achieve large specific surface area and surface activity, and low equipment requirements. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Weigh a certain amount of MAX and put it into a plastic bottle, then use a graduated cylinder to measure 120mL of the prepared alkali solution and put it into a plastic bottle containing MAX, then pass a protective atmosphere (nitrogen, argon, helium can be selected) into the bottle One or several mixed gases) until the air in the plastic bottle is driven away, and finally the plastic bottle is sealed with a sealing film and then shaken at a constant temperature until the reaction is completed, and then the reaction mixture is separated by centrifugation or suction filtration. The separated material is washed with high-purity water or deionized water, and the washed material is vacuum-dried or air-dried to remove moisture, wherein the vacuum-drying temperature does not exceed 100°C. Specific examples are shown in Table 1.

[0023] The reaction conditions of table 1 embodiment 1~10

[0024]

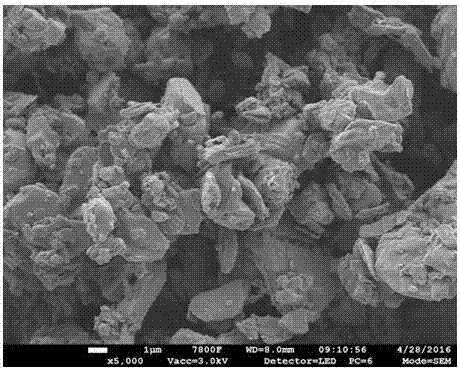

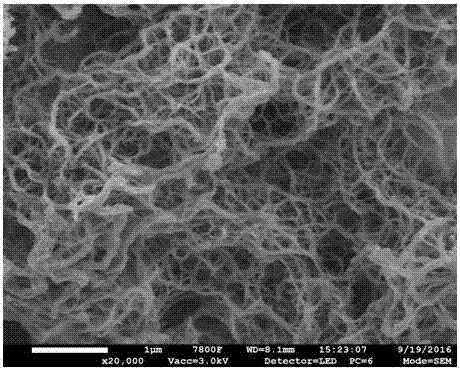

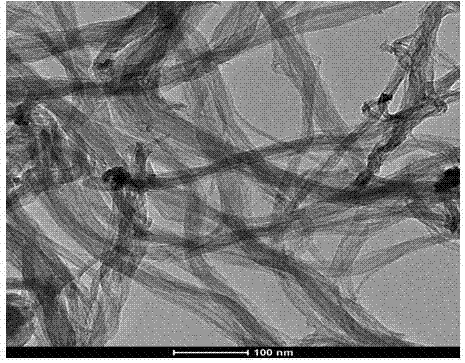

[0025] Analysis explanation: After experimental testing and systematic char...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com