Grid-shaped double-layer photovoltaic component package glue film and preparation method thereof

A photovoltaic module encapsulation and double-layer structure technology, which is applied in photovoltaic power generation, lamination devices, chemical instruments and methods, etc., can solve problems such as the inability to generate electricity on the back of double-sided batteries, and the inability to use the entire layer of highly reflective white packaging film, etc. Achieve the effects of improving photoelectric conversion efficiency, simple structure, and raising the reflective surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

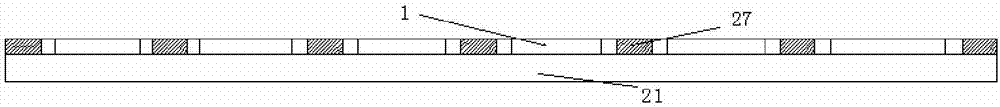

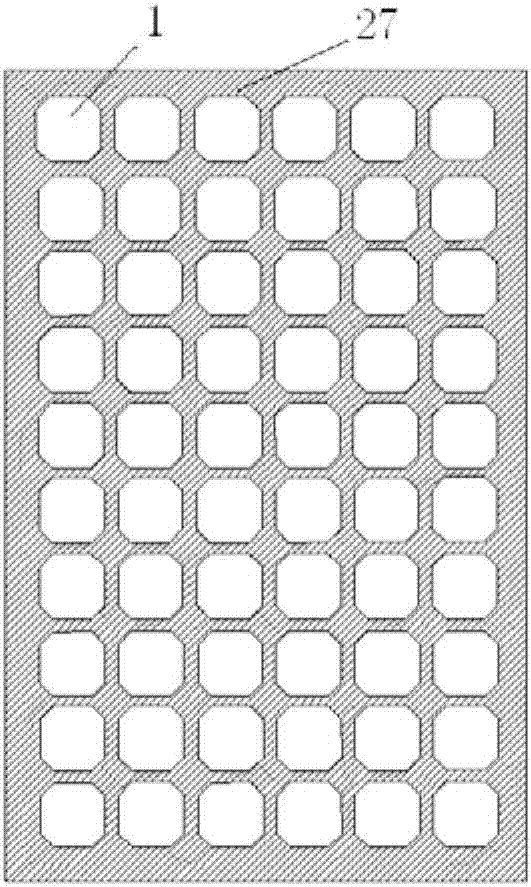

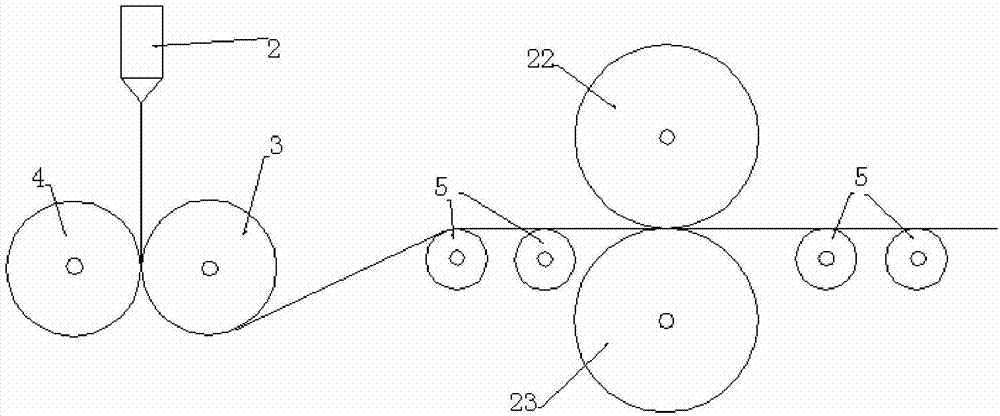

[0039] A method for preparing a grid-like double-layer structure photovoltaic module encapsulation adhesive film, comprising the following steps:

[0040] 1. Use 60wt% ethylene-vinyl acetate copolymer (EVA) and 25wt% ethylene-octene copolymer as the resin substrate, select 5wt% titanium dioxide and 5wt% hollow glass microspheres as high-reflective fillers, and add 5wt% of modification aid vinyltrimethoxysilane, 2wt% of crosslinking aid trimethylolpropane triacrylate and 3wt% of anti-thermal oxygen aging agent 2,2'-methylene-bis-( 4-methyl-6-tert-butylphenol) mixed evenly, extruded at 60-90°C, cast into a film, and fully cooled, such as image 3 As shown, through a pair of knife rolls 22 and the first concave roll 23 that are engaged with each other, the linear speed of the knife roll 22 and the first concave roll 23 is the same as that of the adhesive film production line. Such as Figure 4 As shown, the outer circumference of the knife roller 22 has a plurality of fully enc...

Embodiment 2

[0045] A method for preparing a grid-like double-layer structure photovoltaic module encapsulation adhesive film, comprising the following steps:

[0046] 1. Use 70wt% ethylene-methyl methacrylate copolymer as the substrate, select 5wt% barium sulfate, 5wt% aluminum oxide, and 5wt% talcum powder as high-reflective fillers, and add 10wt% modification additive 3 - (methacryloyl chloride) propyltrimethoxysilane, 1wt% crosslinking aid triallyl isocyanurate and 1wt% crosslinking aid trimethylolpropane triacrylate and 3wt% % of anti-thermal oxygen aging agent 1,3,5-tris(4-tert-butyl-3-hydroxy-2,6-dimethylbenzyl)-1,3,5-triazine-2,4, 6-(1H, 3H, 5H)-triketone is mixed uniformly and then extruded at 60-90°C, cast into a film, and fully cooled, such as Image 6 As shown, first pass through a pair of pin rolls 24 and the second concave roll 25 that are engaged with each other, and the linear speed of the pin roll 24 and the second concave roll 25 is the same as the speed of the film prod...

Embodiment 3

[0051] A method for producing a grid-like double-layer structure photovoltaic module encapsulation film, comprising the following steps:

[0052] 1. Use 40wt% polyethylene (PE), 30wt% polypropylene (PP) and 10wt% ethylene-α-olefin copolymer as the substrate, select 10wt% silica as a high-reflective filler, and add 5wt% Modified auxiliary agent 3-(methacryloyl chloride) propyl trimethyloxysilane, 2wt% crosslinking auxiliary agent triallyl cyanurate and 3wt% anti-thermal oxygen aging agent three (2, 4-Di-tert-butylphenyl) phosphite is mixed evenly and melted, such as Figure 10 As shown, first through the first set of die nozzles 11 and the second set of die nozzles 12 to inject into the mold 13 that circulates and rolls, as Figure 13 As shown, the first set of die head nozzles 11 are 7 continuous spray nozzles arranged in a line along the film width direction, and the edge nozzles 19 on both sides have a width of 5cm; the width of the five middle nozzles 20 is 0.3cm, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com