Method utilizing camellia oleifera shells to prepare plant fiber-based particle board and particle board

A technology of camellia oleifera husk and plant fiber, which is applied in the pretreatment, application, and household components of molding materials, and can solve problems such as environmental pollution, waste of resources, discarding or incineration of camellia oleifera husk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The method for preparing plant fiber-based particle board by utilizing camellia oleifera husk of the present embodiment comprises:

[0028] (1) According to the liquid-solid ratio of 1:10, mix the NaOH solution with a concentration of 2% and the camellia oleifera husk fragments with a diameter of 3mm to 5mm. The pretreatment time is 1h, and the camellia oleifera husk is washed repeatedly until it becomes neutral. After filtering out the moisture in a ventilated place, dry it in an oven at 103°C for subsequent use; (2) after selecting and removing impurities, use the phenolic glue quality as 16% of the quality of the camellia oleifera husk obtained after pretreatment to sizing, and mix evenly (3) Lay the camellia oleifera husk obtained by sizing in the mold, under hot pressing pressure 4MPa, preset density is 0.8 g / m 3 , under the condition of hot pressing temperature of 170° C., hot pressing for 12 minutes to obtain plant fiber-based particle board.

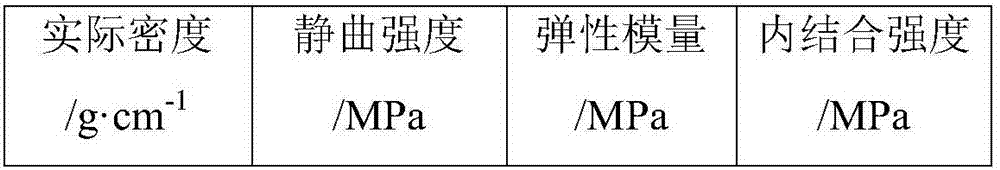

[0029] The perfor...

Embodiment 2

[0034] The method for preparing plant fiber-based particle board by utilizing camellia oleifera husk of the present embodiment comprises:

[0035] (1) Use microwave radiation to pretreat the camellia oleifera shell. Before the pretreatment, soak the camellia oleifera shell in water for 24 hours, the radiation power is 5kW, and the radiation time is 50s; Sizing 16% of the quality of the camellia oleifera shell obtained after pretreatment, and mixing uniformly; (3) laying the camellia oleifera shell obtained by sizing in a mould, at a hot pressing pressure of 4MPa, and a preset density of 0.8g / m 3 , under the condition of hot pressing temperature of 170° C., hot pressing for 12 minutes to obtain plant fiber-based particle board.

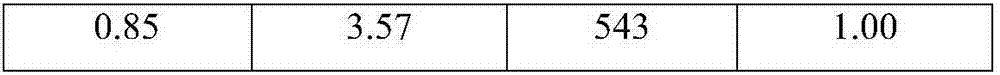

[0036] The performance of the prepared plant fiber-based particle board was tested, and the results are shown in Table 2.

[0037] Table 2: Performance test results of the plant fiber-based particle board prepared by the method of Example 2

[0038...

Embodiment 3

[0040] The method for preparing plant fiber-based particle board by utilizing camellia oleifera husk of the present embodiment comprises:

[0041](1) Soak the camellia oleifera husk in hot water at 70°C for 60 minutes; (2) after selection and removal of impurities, use urea-formaldehyde glue as 16% of the quality of the camellia oleifera husk obtained after pretreatment, and mix well ; (3) Spread the Camellia oleifera husk obtained by sizing in the mould, under hot pressing pressure 4MPa, preset density is 0.8g / m 3 , under the condition of hot pressing temperature of 130° C., hot pressing for 12 minutes to obtain plant fiber-based particle board.

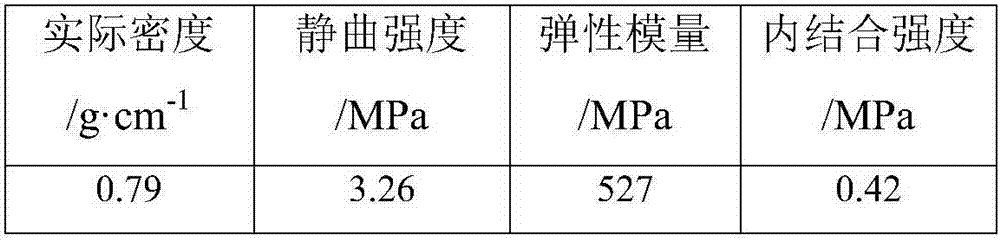

[0042] The performance of the prepared plant fiber-based particle board was tested, and the results are shown in Table 3.

[0043] Table 3: The performance test results of the plant fiber-based particle board prepared by the method of Example 3

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Static bending strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com