Super capacitor device containing millet-husk-based porous active carbon material

A supercapacitor and activated carbon technology, applied in the field of electrochemical applications, can solve the problems of poor control of mesopore ratio, high cost of porous carbon, and attenuation of specific capacitance value, and achieve good wettability, high energy density, and improved energy density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

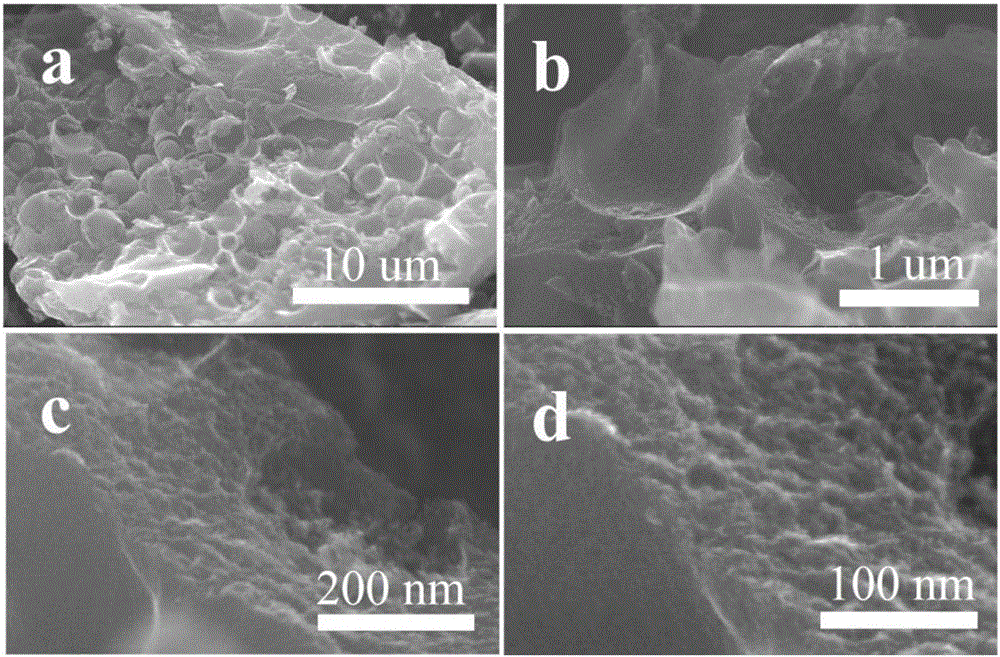

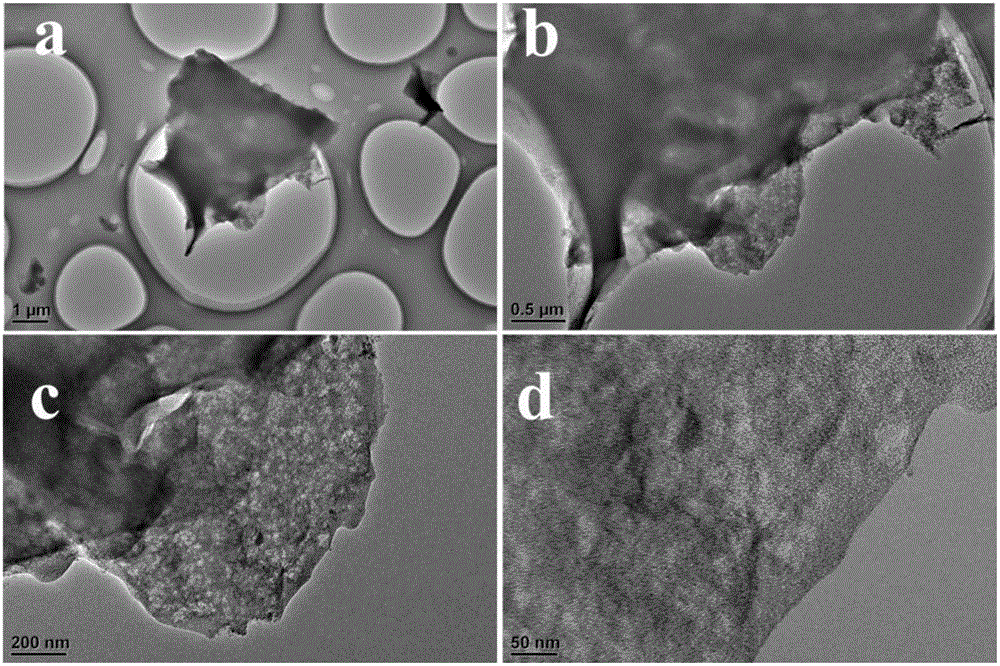

[0035] Step 1: Mix the dried millet skin and ammonium dihydrogen phosphate uniformly, with a mass ratio of 1:2, and then use microwaves to activate carbonization under the protection of an inert gas. minute;

[0036] Step 2: Carbonize and activate the black powder, add distilled water, filter and wash until the pH value is 6.4-7, and then dry, and the obtained powder is the prepared millet bark-based porous activated carbon material;

[0037] Step 3: prepare millet-based porous activated carbon material and PTFE by microwave method, add distilled water to mix into slurry according to the ratio of mass ratio 97:3, and repeatedly roll the thin sheet electrode material obtained by slurry, and the electrode material Put it on a current collector of a corresponding size, cold press it at 5 MPa for 20 seconds, and then dry it at 120°C to obtain an electrode sheet for a supercapacitor, wherein the electrode material is greater than 14 mg per square centimeter;

[0038] Step 4: Assem...

Embodiment 2

[0041] Step 1: Mix the dried millet skin and ammonium hydrogen phosphate uniformly, the mass ratio is 1:1.5, and then use microwave to activate carbonization under the protection of inert gas, the power is 900W, microwave radiation for 30 minutes, and then use microwave to keep warm for 5 minutes ;

[0042] Step 2: Carbonize and activate the black powder, add distilled water, filter and wash until the pH value is 6.4-7, and then dry, and the obtained powder is the prepared millet bark-based porous activated carbon material;

[0043] Step 3: Prepare millet-based porous activated carbon material and styrene-butadiene rubber by microwave method, add distilled water and mix them into slurry according to the ratio of mass ratio 96:4, and repeatedly roll the thin sheet-shaped electrode material obtained by slurry. The electrode material is placed on a current collector of a corresponding size, cold-pressed at 5 MPa for 30 seconds, and then dried at 120°C to obtain an electrode sheet...

Embodiment 3

[0047] Step 1: Mix the dried millet skin and ammonium dihydrogen phosphate uniformly, the mass ratio is 1:2, and then use microwave to activate carbonization under the protection of inert gas, the power is 800W, microwave radiation for 50 minutes, and then use microwave to keep warm minute;

[0048] Step 2: Carbonize and activate the black powder, add distilled water, filter and wash until the pH value is 6.4-7, and then dry, and the obtained powder is the prepared millet bark-based porous activated carbon material;

[0049] Step 3: Prepare millet bark-based porous activated carbon material and carboxymethyl cellulose by microwave method, add distilled water to mix into slurry according to the ratio of mass ratio 96:4, and repeatedly roll the thin sheet-shaped electrode material obtained by slurry. The electrode material is placed on a current collector of a corresponding size, cold-pressed at 3 MPa for 60 seconds, and then dried at 120°C to obtain an electrode sheet for a sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com