Preparation method for rare-earth-modified graphene reinforced metal matrix composite bar

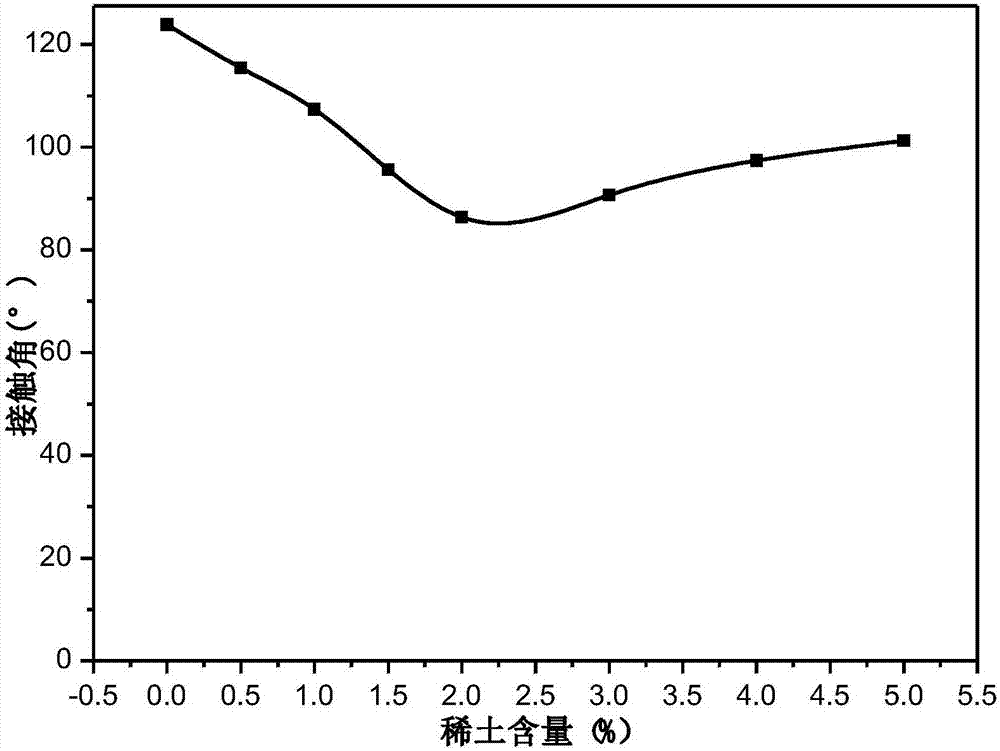

A technology of metal matrix composite and rare earth modification, applied in the direction of graphene, nano-carbon, etc., can solve the problems of poor wettability and poor dispersion, and achieve the effects of high density, reduced oxidation, and high-strength thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Prepare a rare earth solution using ethanol as a solvent, wherein the mass fractions of the various components of the rare earth solution are: 0.05% of rare earth compounds, 2.0% of ammonium chloride, 0.01% of urea, and 0.3% of sodium dimercaptopropanesulfonate; Heating to 75° C., keeping the temperature for 10 minutes, and then adjusting the pH of the rare earth solution to 5 with nitric acid to obtain a rare earth modified solution. According to the ratio of 200mg / mL, the graphene oxide was immersed in the rare earth modified solution at 18°C, and ultrasonically dispersed for 3 hours, with an ultrasonic power of 2000W and a frequency of 20KHz, to obtain a modified graphene oxide dispersion. Subsequently, a hydrazine hydrate solution with a mass concentration of 80% was added to the modified graphene oxide dispersion liquid, and the modified graphene oxide dispersion liquid and hydrazine hydrate were reduced according to a volume ratio of 10:7 to obtain a graphene solut...

Embodiment 2

[0050] Prepare a rare earth solution with ethanol as a solvent, wherein the mass fraction of the various components of the rare earth solution is: 5.0% of rare earth compound, 0.1% of ammonium chloride, 2.0% of urea, and 0.15% of sodium dimercaptopropanesulfonate; Heating in a water bath to 85° C., keeping the temperature for 5 minutes, and then adjusting the pH of the rare earth solution to 6 with nitric acid to obtain a modified rare earth solution. According to the ratio of 500mg / mL, the graphene oxide was immersed in the rare earth modified solution at 22°C, and ultrasonically dispersed for 6 hours, with an ultrasonic power of 900W and a frequency of 75KHz, to obtain a modified graphene oxide dispersion. Subsequently, a hydrazine hydrate solution with a mass concentration of 80% was added to the modified graphene oxide dispersion, and the modified graphene oxide dispersion and hydrazine hydrate were reduced to obtain a graphene solution in a volume ratio of 10:10. Then, it...

Embodiment 3

[0052] Prepare a rare earth solution using ethanol as a solvent, wherein the mass fractions of the various components of the rare earth solution are: 3% of rare earth compounds, 1% of ammonium chloride, 1% of urea, and 0.2% of sodium dimercaptopropanesulfonate; Heating to 80° C., keeping the temperature for 7 minutes, and then adjusting the pH of the rare earth solution to 5 with nitric acid to obtain a rare earth modified solution. According to the ratio of 300mg / mL, the graphene oxide was immersed in the rare earth modified solution at 20°C, and ultrasonically dispersed for 4 hours, with an ultrasonic power of 1500W and a frequency of 55KHz, to obtain a modified graphene oxide dispersion. Subsequently, a hydrazine hydrate solution with a mass concentration of 80% was added to the modified graphene oxide dispersion, and the modified graphene oxide dispersion and hydrazine hydrate were reduced to obtain a graphene solution in a volume ratio of 10:8. Then, it was washed several...

PUM

| Property | Measurement | Unit |

|---|---|---|

| carrier mobility | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com