A turntable fixture

A turntable and fixture technology, applied in the direction of manufacturing tools, auxiliary welding equipment, welding equipment, etc., can solve the problems of reducing production efficiency, increasing production costs, low welding quality, etc., and achieve high production efficiency, zero scrap rate, and reliable welding quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

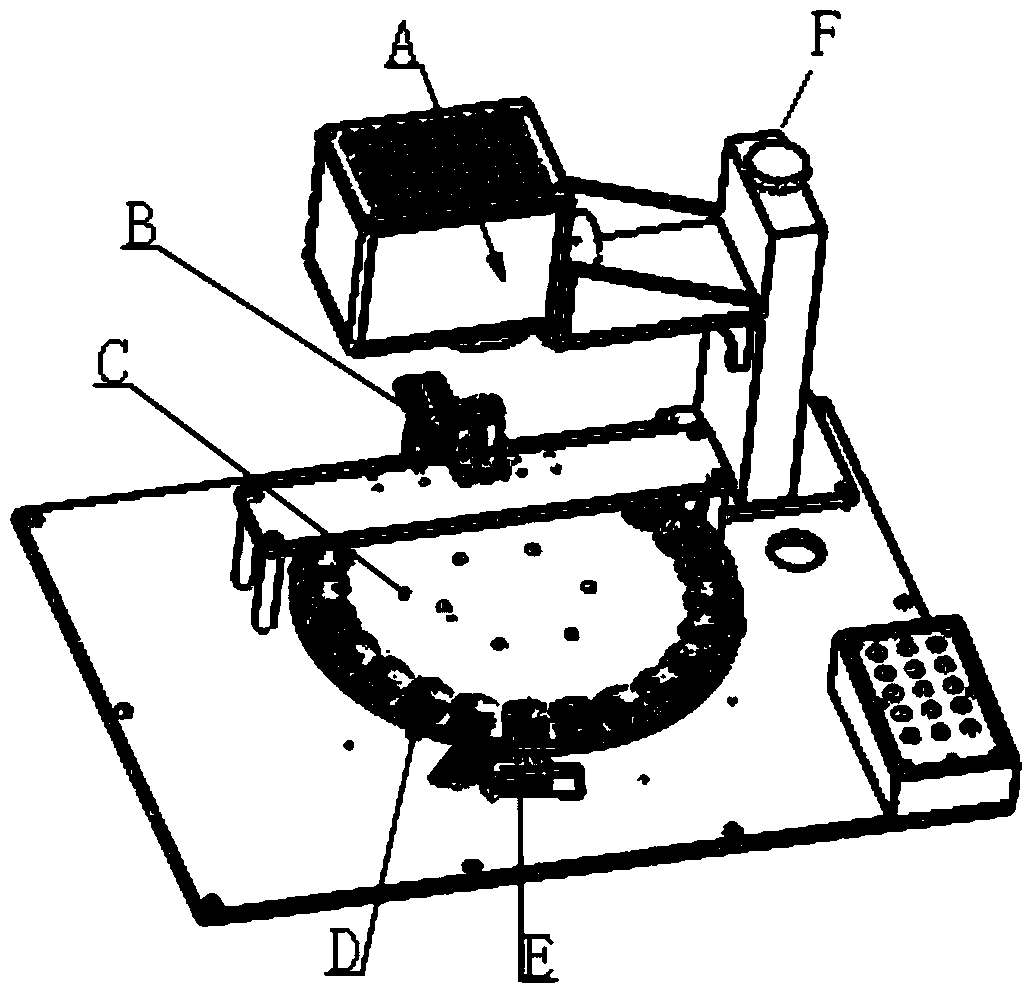

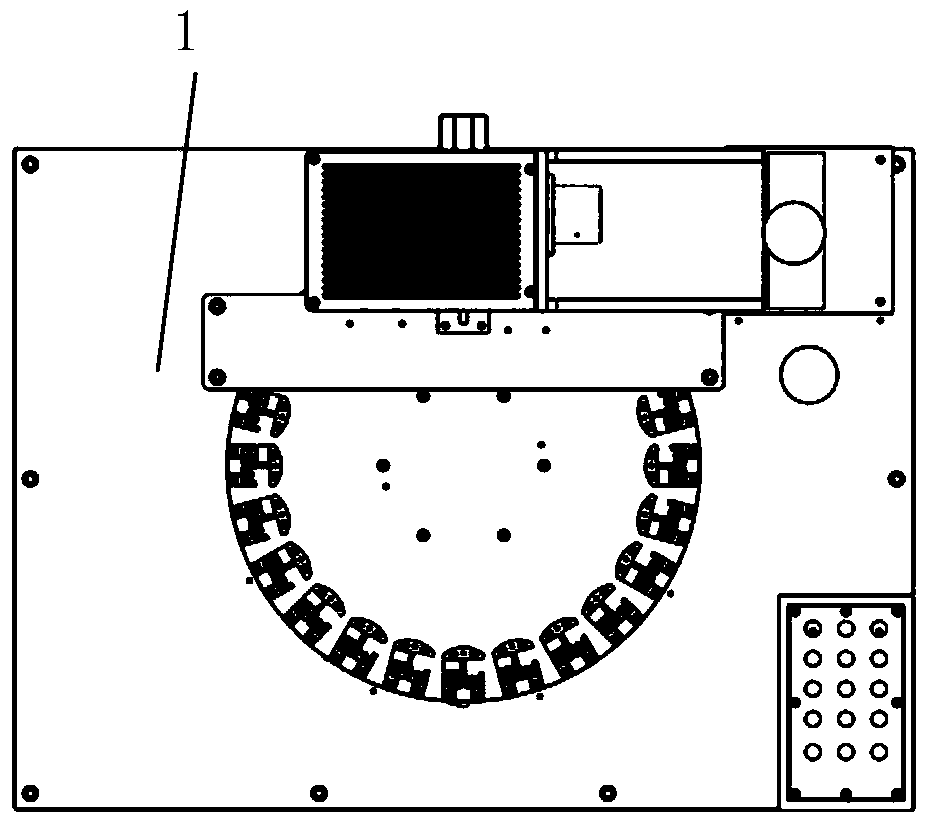

[0024] see figure 1 - Figure 7 , a turntable fixture of the present invention, comprising a turntable assembly, a vibrating mirror lifting assembly, a vibrating mirror welding head assembly, a pressing assembly, a traveling fixture, and a blanking assembly, wherein the traveling fixture is fixed on the turningtable assembly, and the pressing assembly is located on the accompanying Above the fixture, the blanking assembly is located below the accompanying fixture, the vibrating mirror lifting assembly is fixed on the large platen, the turntable assembly and the blanking assembly are installed on the large platen, and the vibrating mirror welding head assembly is connected to the vibrating mirror lifting assembly.

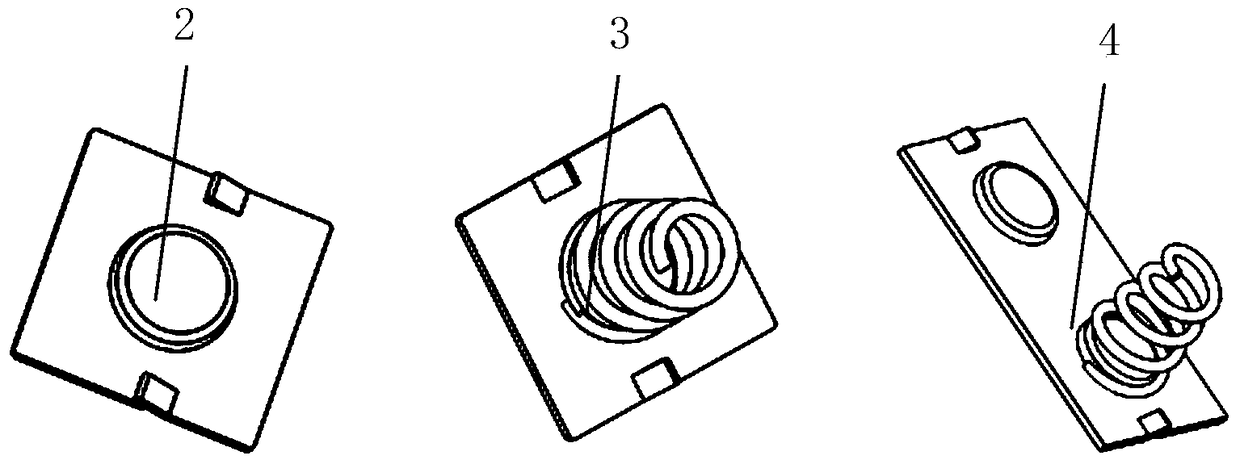

[0025] Wherein, the accompanying fixture includes a fixture bottom plate, an adjustment block, a strong magnetic magnet, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com