Solar cooperative two-step biomass spiral baking pretreatment method and apparatus thereof

A pretreatment device, biomass technology, applied in the directions of biofuel, waste fuel, energy input, etc., can solve the problems of prolonging residence time, reducing production efficiency, increasing cost, etc., to improve energy utilization, improve production efficiency, The effect of reducing dwell time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

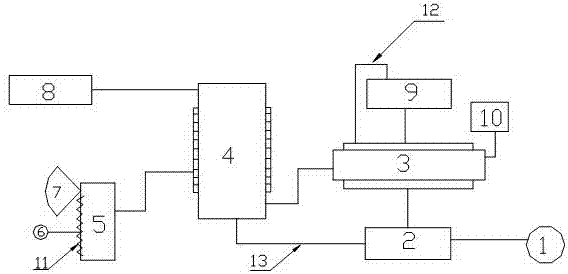

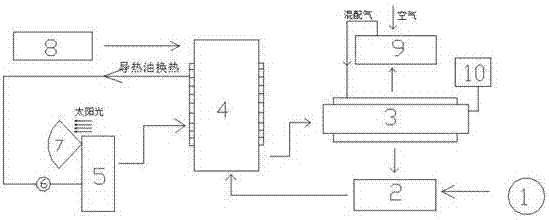

[0047] A method for solar energy synergistic two-step biomass spiral roasting pretreatment, comprising the following steps:

[0048] S1. Using solar energy as an auxiliary heat source and synergizing with the combustion of roasted volatiles for biomass roasting pretreatment, specifically drying and dehydrating corn stalks (size below 30mm) with a moisture content of 15% and size treatment (truncated) (The drying and dehydration temperature is 120°C, the residual moisture of corn stalks is 2.5-3%), and the feed rate is 5kg / h;

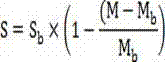

[0049] S2. Use diesel combustion to preheat the biomass spiral roasting reactor to 260°C, send the dried and dehydrated corn stalks into the biomass spiral roasting reactor for roasting reaction, and stop diesel combustion after the roasted volatiles can be ignited The solid-phase product obtained after roasting can be stored or used in the next stage after cooling. The roasted volatiles are mixed with air for combustion. The high-temperature hot flue ga...

Embodiment 2

[0052] A method for solar energy synergistic two-step biomass spiral roasting pretreatment, comprising the following steps:

[0053] S1. Using solar energy as an auxiliary heat source and synergizing with the combustion of roasted volatiles for biomass roasting pretreatment, specifically drying and dehydrating rice husks (size below 30mm) with a moisture content of 14% and size treatment (truncated) (The temperature of drying and dehydration is 125°C, the residual moisture of rice husk is 4-5%), and the feed rate is 4.8kg / h;

[0054] S2. Use diesel combustion to preheat the biomass spiral roasting reactor to 300°C, send the dried and dehydrated rice husks into the biomass spiral roasting reactor for roasting reaction, and stop diesel combustion after the roasted volatiles can be ignited The solid-phase product obtained after roasting can be stored or used in the next stage after cooling, and the roasted volatiles are mixed with air for combustion. The high-temperature hot flue...

Embodiment 3

[0057] A method for solar energy synergistic two-step biomass spiral roasting pretreatment, comprising the following steps:

[0058] S1. Using solar energy as an auxiliary heat source and synergizing with the combustion of roasted volatiles for biomass roasting pretreatment, specifically drying and dehydrating camellia oleifera shells with a moisture content of 15% (the temperature for drying and dehydration is 130°C, and the residual moisture of camellia oleifera shells 1.5~2.5%), the feed rate is 4kg / h;

[0059] S2. Use diesel combustion to preheat the biomass spiral roasting reactor to 330°C, send the dried and dehydrated camellia oleifera shells into the biomass spiral roasting reactor for roasting reaction, and stop diesel combustion after the roasted volatiles can be ignited The solid-phase product obtained after roasting can be stored or used in the next stage after cooling, and the roasted volatiles are mixed with air for combustion. The high-temperature hot flue gas g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com