Method for preparing river mud sintered brick

A technology of river silt and sintered bricks, which is applied in the field of building materials, can solve the problems of complex process and long period, complex and diverse ingredients, low yield of fired bricks, etc., achieve high controllability and operability, improve production efficiency, and save water resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A preparation method of river silt sintered bricks, comprising:

[0021] Adding a modifier to the screened and removed river silt, and dehydrating to make the first silt material;

[0022] Stirring the first sludge material, and pressing to obtain brick adobe;

[0023] Drying the adobe at room temperature and drying room in sequence to obtain the adobe to be fired;

[0024] After the adobe to be fired is pre-fired in the range of 400-600°C, the temperature is raised continuously and the second-stage firing is carried out in the range of 850-1000°C.

[0025] Specifically:

[0026] Sludge preparation, river and lake sludge is sieved to remove impurities; pumped river and lake silt to the grid to sieve and remove impurities, then add modifier, and then filter through plate and frame filter press to form the first sludge material for standby, usually silt cake;

[0027] Preferably, the sand content of the first sludge material is ≤35%.

[0028] The particle size of the...

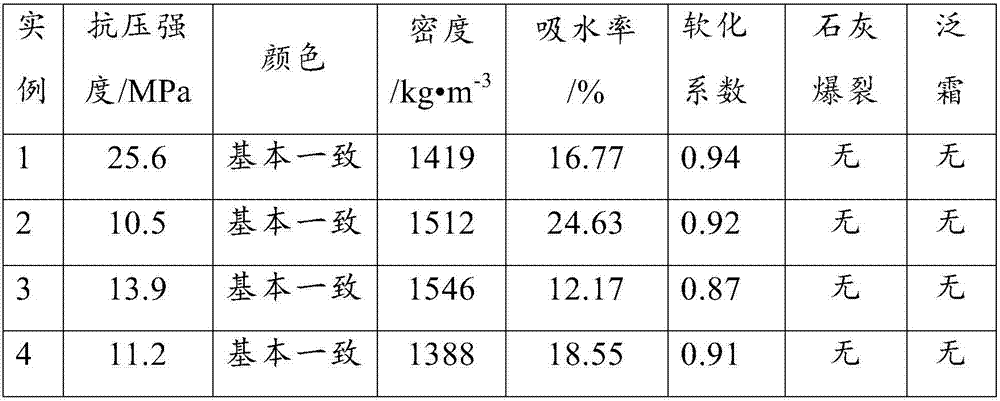

Embodiment 1

[0038] Add the modifier into the sludge, and mechanically dehydrate it through a plate and frame filter press to a moisture content of 21%; then stir with a strong mixer, press the stirred sludge into bricks, dry naturally and dry in a drying room, and then bake in an electric furnace. First pre-fire at 400°C for 60 minutes, then raise the temperature to 850°C with the furnace and keep it for 240 minutes; cool to room temperature with the furnace to obtain the product. The performance test results are shown in Table 1.

Embodiment 2

[0040] Add the modifier into the sludge, and mechanically dehydrate it through a plate and frame filter press to a moisture content of 26%; then stir it with a strong mixer, press the stirred sludge into bricks, dry naturally and dry in a drying room, and then bake in an electric furnace. First pre-fire at 450°C for 55 minutes, then raise the temperature to 900°C with the furnace and keep it for 180 minutes; cool to room temperature with the furnace to obtain the product. The performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com