Method for improving heat dissipation performance of metal middle frame and structure of metal middle frame

A technology of metal middle frame and heat dissipation performance, which is applied in the direction of telephone structure, semiconductor/solid-state device components, semiconductor devices, etc. The effect of improving heat dissipation performance and good heat uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

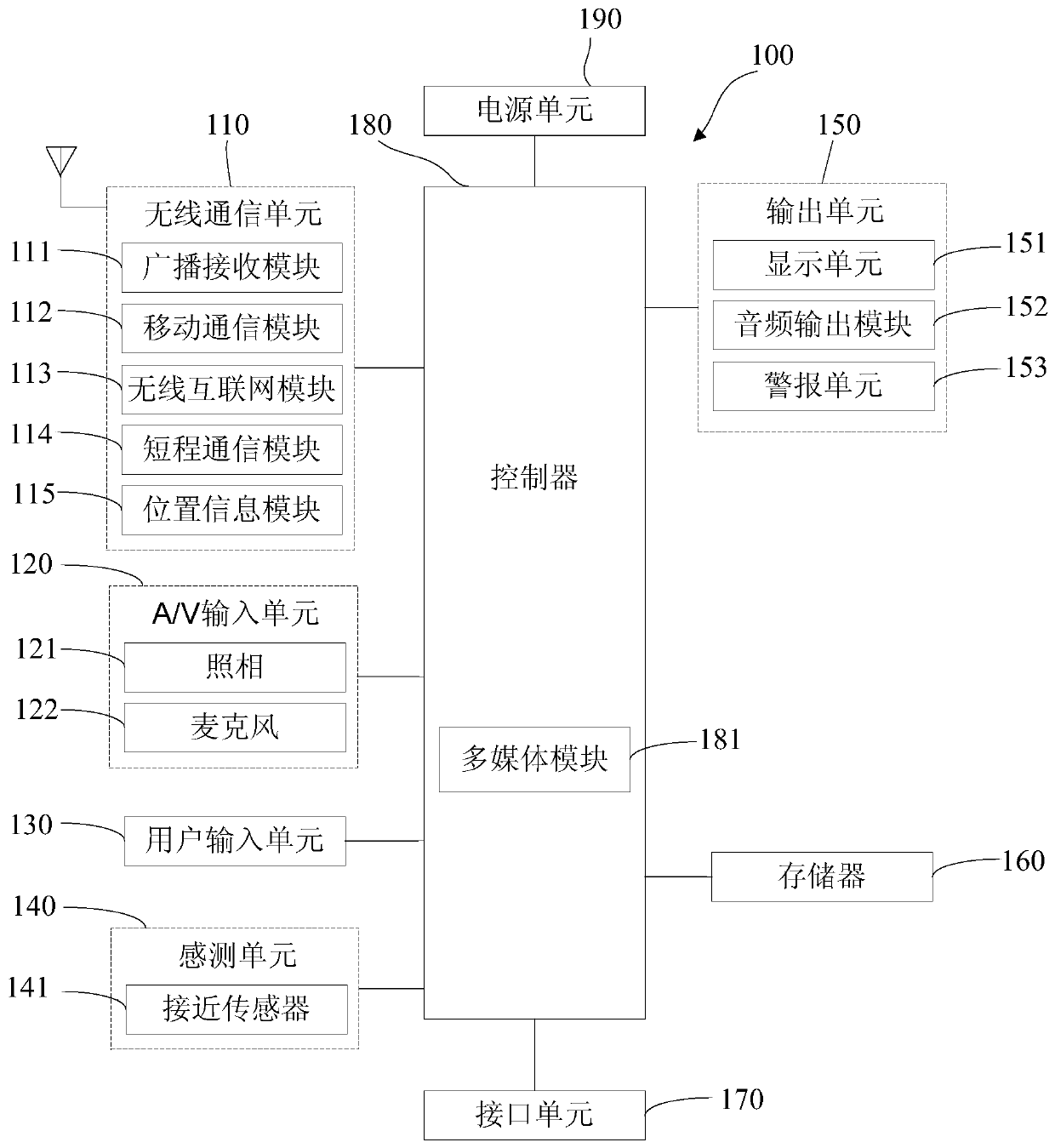

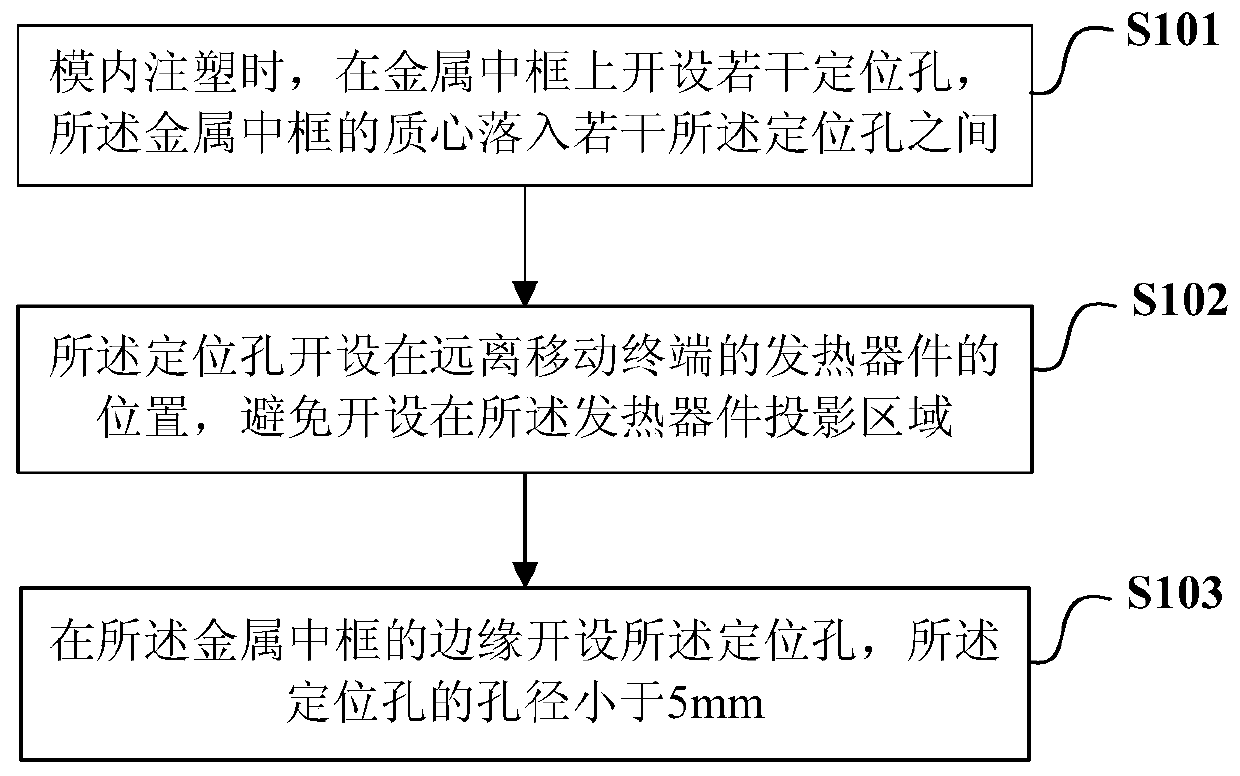

[0070] In order to solve the above technical defects, refer to the attached figure 1 , a method for improving the heat dissipation performance of a metal middle frame provided by the present invention, the method includes the following steps:

[0071] S101. During in-mold injection molding, several positioning holes are opened on the metal middle frame, and the center of mass of the metal middle frame falls between the several positioning holes;

[0072] S102. The positioning hole is set at a position away from the heating device of the mobile terminal, avoiding opening in the projection area of the heating device;

[0073] S103. Open the positioning hole on the edge of the metal middle frame, and the diameter of the positioning hole is less than 5mm.

[0074] Setting the positioning holes on the metal middle frame will significantly change the heat conduction path of the metal middle frame and affect the heat dissipation effect of the metal middle frame. Therefore, it is n...

Embodiment 2

[0076] In addition, in order to achieve the above purpose, the present invention also proposes a metal middle frame structure, which includes a middle frame body 400 and several positioning holes 430 opened in the middle frame body, and the positioning holes 430 are located in the middle frame body 400 The edge and away from the projection area of the heat generating device of the mobile terminal 100; the diameter of the positioning hole 430 is less than 5mm.

[0077] Wherein, the thickness of the middle frame body 400 is 0.4mm-0.6mm, and the material of the middle frame body 400 is one of aluminum alloy 6063, aluminum-titanium alloy, aluminum-magnesium alloy and stainless steel. The metal middle frame material of the mobile terminal is a direct protection for the mobile phone in the face of extrusion or force. The higher the strength of the metal middle frame material, the less likely the mobile terminal will be deformed, which is also a protection for the use of the mobile...

Embodiment 3

[0084] Such as Figure 4 , 5 As shown, three positioning holes 430 are opened on the middle frame body 400 , and the center of mass of the middle frame body 400 falls in the triangular area formed by the three positioning holes 430 .

[0085] Such as Figure 4 As shown, the heat generating device of the mobile terminal 100 includes several heat generating chips 410 and a backlight 420, and the projection areas of the heat generating chips 410 and the back light 420 are respectively at both ends of the middle frame body 400, two of which The positioning hole 430 is opened on both sides of the projection area of the backlight 420 , close to the edge of the middle frame body 400 , and the other positioning hole 430 is opened on the side of the projection area of the heating chip 410 in the middle frame body 400 edge, away from the projection area of the heating chip 410 .

[0086] Such as Figure 5 As shown, the heat generating device of the mobile terminal includes sev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com