Folded thin film capacitor and fabrication method thereof

A technology of film capacitors and manufacturing methods, which is applied in the direction of film/thick film capacitors, laminated capacitors, fixed capacitor leads, etc., can solve the problem that the small contact area cannot effectively improve the contact resistance of the electrode end, which is easy to fall off, and the energy storage density of the capacitor Problems such as drop and increase of non-stacked parts can solve the problems of less contact points, reduce current density and loss, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] 下面结合附图对本发明的具体技术方案作进一步地描述。

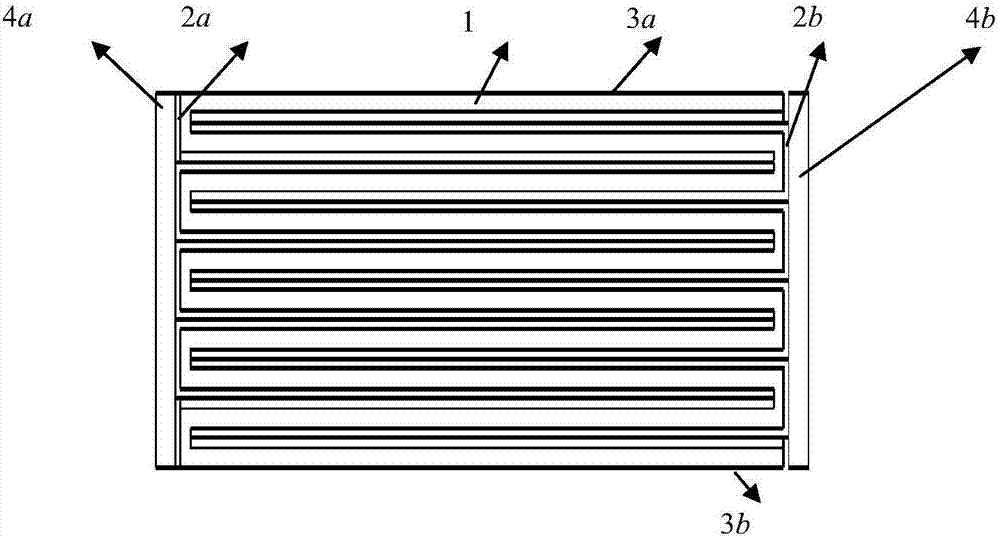

[0029] Such as Figure 3-4 所示,本发明的一种折叠薄膜电容器,薄膜电容器具有多层金属化薄膜相互折叠而成的层叠体,且金属化薄膜的有机薄膜和金属蒸镀膜为交替层叠的方式,需要说明的是,本发明的薄膜折叠薄膜电容器中的金属化薄膜的折叠层数不受附图的任何限制。

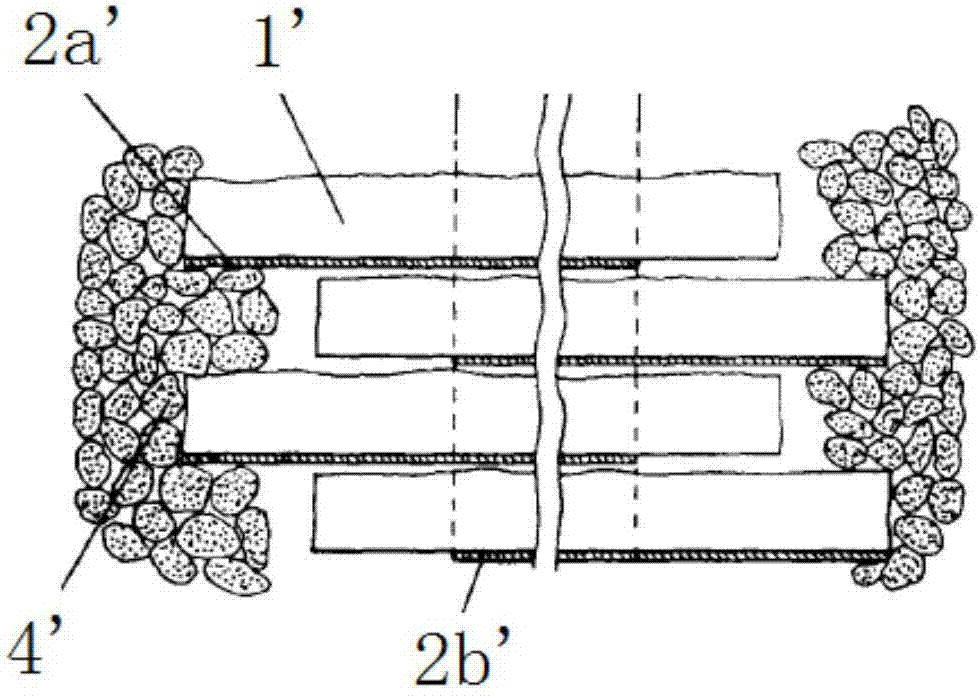

[0030] 通过折叠在薄膜电容器的两个侧面以整面的方式存在金属蒸镀膜,通过在侧面的金属蒸镀膜上喷镀金属粒子而形成喷金层4a和4b,喷金层可靠地与侧面的金属蒸镀膜连接在一起。上述两个喷金层的构成材料没有特别限制,可将锌、铝等一直以来常规使用的物质作为两个喷金层的构成材料使用。需要说明的是,根据需要,在上述喷金层上可分别连接图上未给出的端子等。

[0031] 金属化薄膜包括有机薄膜1和在有机薄膜1的表明蒸镀金属后形成的金属蒸镀膜2a和2b,有机薄膜为聚丙烯、聚苯硫醚、聚酯、聚苯乙烯或聚碳酸酯,有机薄膜1的两侧边缘设有未蒸镀金属蒸镀膜的空白留边3a和3b。金属化薄膜的有机薄膜1和金属蒸镀膜的各自厚度没有特别限制,但通常有机薄膜1的厚度为1μm~25μm,金属蒸镀膜的厚度在0.3nm~30nm左右。

[0032] 需要说明的是,为了使本发明的薄膜折叠薄膜电容器的结构容易理解,分别以夸大的尺寸表示出了金属化薄膜的有机薄膜1及金属蒸镀膜、喷金层的厚度,同时还以极少于实际数目的数目例示了薄膜电容器中金属化薄膜的折叠层数。

[0033] 为增加喷金层和金属蒸镀膜之间的附着,可在折叠时将相邻电极层之间进行错边,即相互相邻的金属化膜以使其中的一个金属化膜端部从另一个 金属化膜的端部突出的方式相互叠合,由此同一电极中相邻两个金属化膜形成缝隙,从而使喷镀金属粒子可侵入到缝隙内,与缝隙及突出部分的金属蒸镀膜紧密 connect.

[0034] 本发明的折叠薄膜电容器的制作方法是,包括以下步骤:

[0035]1) Taking material and trimming: Use a film cutter to cut the metallized film raw material into the required width of the capacitor. The metallized fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com