A Fault Diagnosis Method for Chemical Processes Based on Multilayer Optimization pcc-sdg

A PCC-SDG and fault diagnosis technology, which is applied in the direction of instruments, adaptive control, control/regulation systems, etc., can solve the problems of difficult application, insignificant fault diagnosis effect of the whole process, and less research on quantitative modeling methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

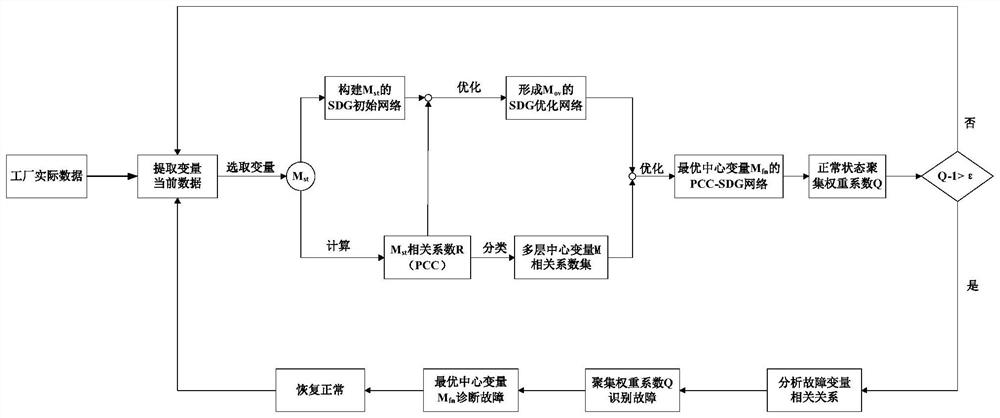

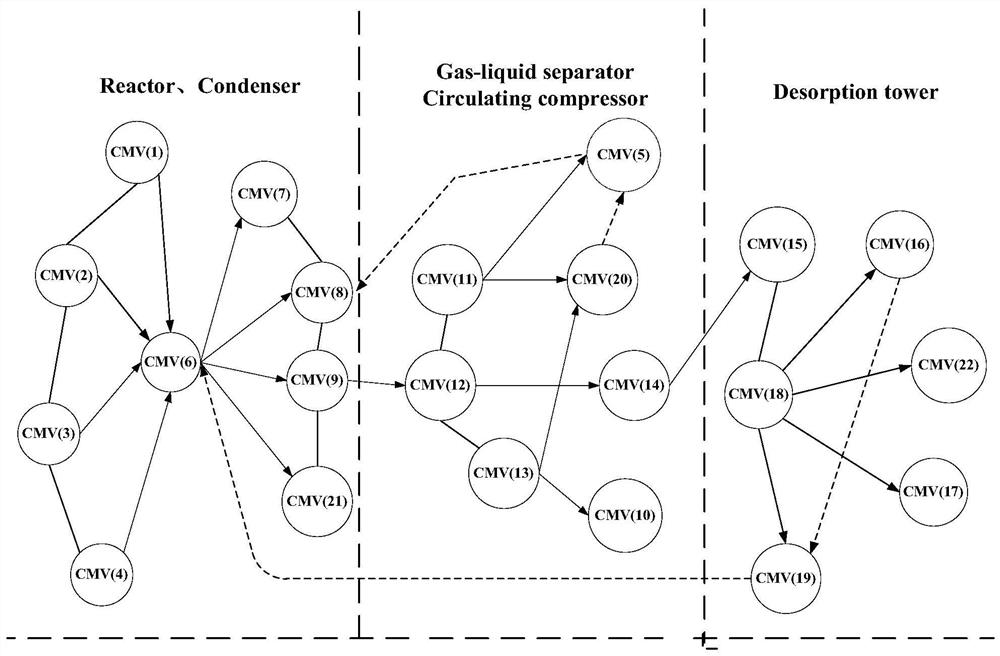

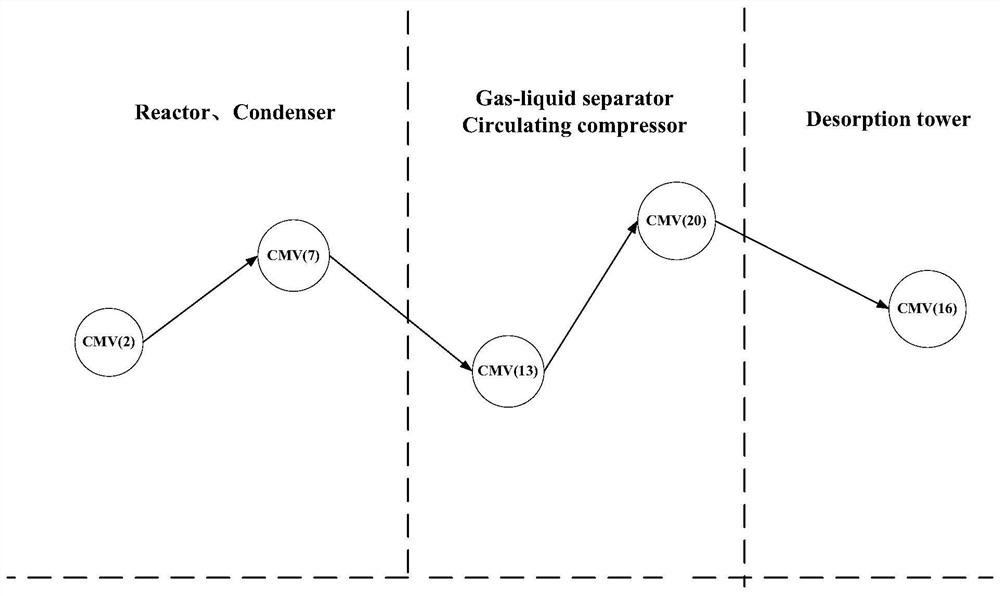

[0030] Such as figure 1 As shown, a multi-layer optimized PCC-SDG chemical process fault diagnosis method is described in the form of a flow block diagram, including SDG depth mining process information, PCC quantitative optimization fault diagnosis, and the like, the specific steps are as follows:

[0031] (1) Analyze the TE (Tennessee Eastman) process and select 22 Continuous measurement variables, establish a symbol-to-picture (SDG) initial network;

[0032] (2) Extract the real-time data segment of the TE process variable to build data vector sets and perform correlation coefficient analysis, and the correlation coefficient acceptance is set, and the initial threshold is determined;

[0033] (3) Select the initial feature variable using the Pearson relationship between correlation analysis, and establish a variable correlation coefficient array for weight analysis;

[0034] (4) Weight Analysis and Process Analysis of the TE Process Composition Array Determination Determination...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com