Electrowetting display device capable of controlling ink movement and preparation method thereof

An electrowetting display and oil column technology, which is applied in the direction of instruments, optics, optical components, etc., can solve the problems of low ink movement efficiency, loss of aperture ratio, and difficult edge smoothing, etc., to achieve a process that is controllable, The effect that the process is easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

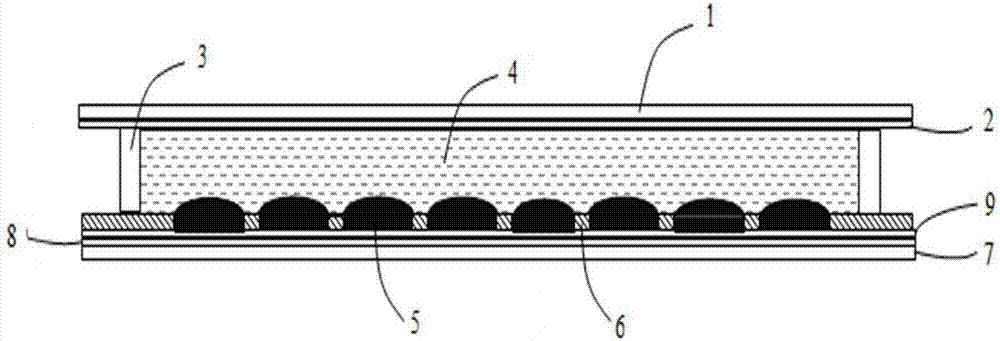

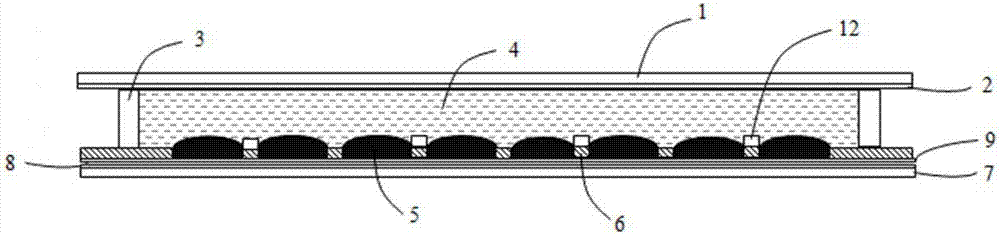

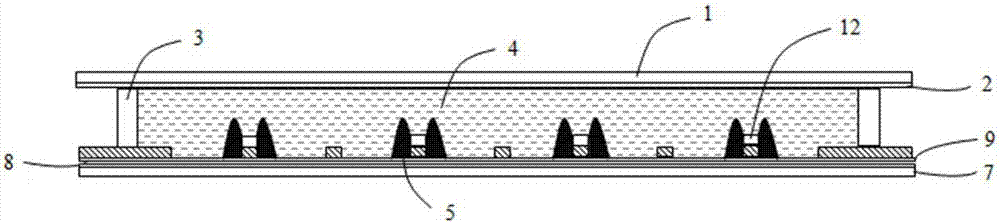

[0047] figure 2 It is a structural schematic diagram of an electrowetting display with an oil control column structure according to the present invention. The main structure is composed of two immiscible polar electrolyte liquids 4 and non-polar liquids 5 filled in the sealed cavity formed by the upper and lower substrates and the two substrates facing each other. composition. The upper substrate is composed of an upper support plate 1 , a first electrode 2 and a sealant 3 , and the lower substrate is composed of a lower support plate 7 , a second electrode 8 , a hydrophobic insulating layer 9 , a pixel wall 6 and an oil control column 12 .

[0048] The oil control column 12 is directly formed above the pixel wall 6 by secondary photolithography, and the shape of the oil control column 12 is a cylindrical or polygonal columnar structure.

[0049] Since the pixel walls form a closed space to accommodate the first fluid, the vertical and horizontal pixel walls will intersect t...

Embodiment 2

[0057] The preparation of electrowetting display has the following two methods

[0058] Method one, such as Figure 7 Shown:

[0059] A1. The preparation method of the conductive layer in the display device has been standardized, so the preparation method of the first electrode 2 and the second electrode 8 in the upper and lower substrates will not be repeated here.

[0060] B1. Coating the solution of the hydrophobic insulating layer 9 on the surface of the lower support plate 7 with the second electrode 8 by methods such as spin coating, blade coating, slit coating, silk screen printing, and flexo printing, and performing thermal curing treatment.

[0061] C1. Apply the photoresist material 6' evenly on the surface of the hydrophobic insulating layer 9. The coating method can be spin coating, blade coating, slit coating, screen printing, roller coating and other methods.

[0062] Before coating, in order to better allow the photoresist material to form a film on the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com