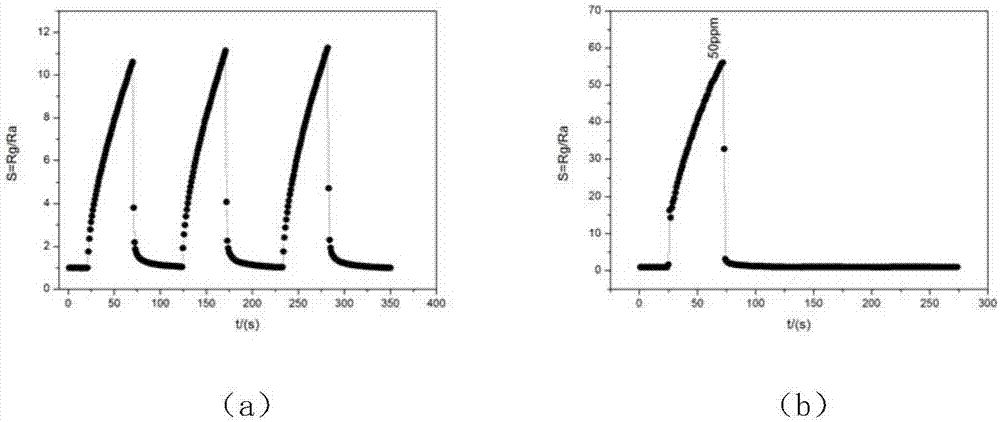

ZnO nanowall RGO heterojunction photoelectric gas sensor and preparation method thereof

A gas sensor, nano wall technology, applied in the direction of material resistance, can solve the problem of low sensitivity, and achieve the effect of high light sensitivity, good stability and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment one: a kind of preparation method of ZnO nano wall RGO heterojunction photoelectric sensitive sensor, comprises the following steps:

[0045] 1. Preparation of porous reduced graphene

[0046] Weigh 2mg of porous graphene powder (Nanjing Jicang Nano Technology Co., Ltd.), mix it with 10ml of DMF (N,N-dimethylformamide), and prepare a concentration of 0.2mg / ml porous graphene-DMF (N, N-dimethylformamide) suspension, then seal the above suspension with multi-layer plastic wrap, discontinuous ultrasonic treatment at room temperature for 72h, to obtain a porous graphene dispersion, leave it for 24h, and pass through at a speed of Centrifuge at 4000r / min, then absorb the upper layer liquid into a clean glass bottle, the porous graphene dispersion; ultrasonically clean the Ag interdigitated electrodes in acetone, absolute ethanol, and deionized water respectively, and put them in at a temperature of 110 Preheat treatment in a drying oven at ℃ for 1h; take 1ml of t...

Embodiment 2

[0057] A preparation method of ZnO nano-wall RGO heterojunction photoelectric sensitive sensor, comprising the following steps:

[0058] 1. Preparation of porous reduced graphene

[0059] Weigh 4mg of porous graphene powder (Nanjing Jicang Nano Technology Co., Ltd.), mix it with 10ml of DMF (N,N-dimethylformamide), and prepare a concentration of 0.4mg / ml porous graphene-DMF (N, N-dimethylformamide) suspension, then seal the above suspension with multi-layer plastic wrap, discontinuous ultrasonic treatment at room temperature for 72h, to obtain a porous graphene dispersion, leave it for 24h, and pass through at a speed of Centrifuge at 4000r / min, and then absorb the upper layer liquid into a clean glass bottle to form a porous graphene dispersion; ultrasonically clean the Ag interdigitated electrodes in acetone, absolute ethanol, and deionized water respectively, and place them at a temperature of 110°C Preheat treatment in a drying oven for 1h; take 1ml of the configured poro...

Embodiment 3

[0070] A preparation method of ZnO nano-wall RGO heterojunction photoelectric sensitive sensor, comprising the following steps:

[0071] 1. Preparation of porous reduced graphene

[0072] Weigh 6mg of porous graphene powder (Nanjing Jicang Nano Technology Co., Ltd.), mix it with 10ml of DMF (N,N-dimethylformamide), and prepare a concentration of 0.6mg / ml porous graphene-DMF (N, N-dimethylformamide) suspension, then seal the above suspension with multi-layer plastic wrap, discontinuous ultrasonic treatment at room temperature for 72h, to obtain a porous graphene dispersion, leave it for 24h, and pass through at a speed of Centrifuge at 4000r / min, and then absorb the upper layer liquid into a clean glass bottle to form a porous graphene dispersion; ultrasonically clean the Ag interdigitated electrodes in acetone, absolute ethanol, and deionized water respectively, and place them at a temperature of 110°C Preheat treatment in a drying oven for 1h; take 1ml of the configured poro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com