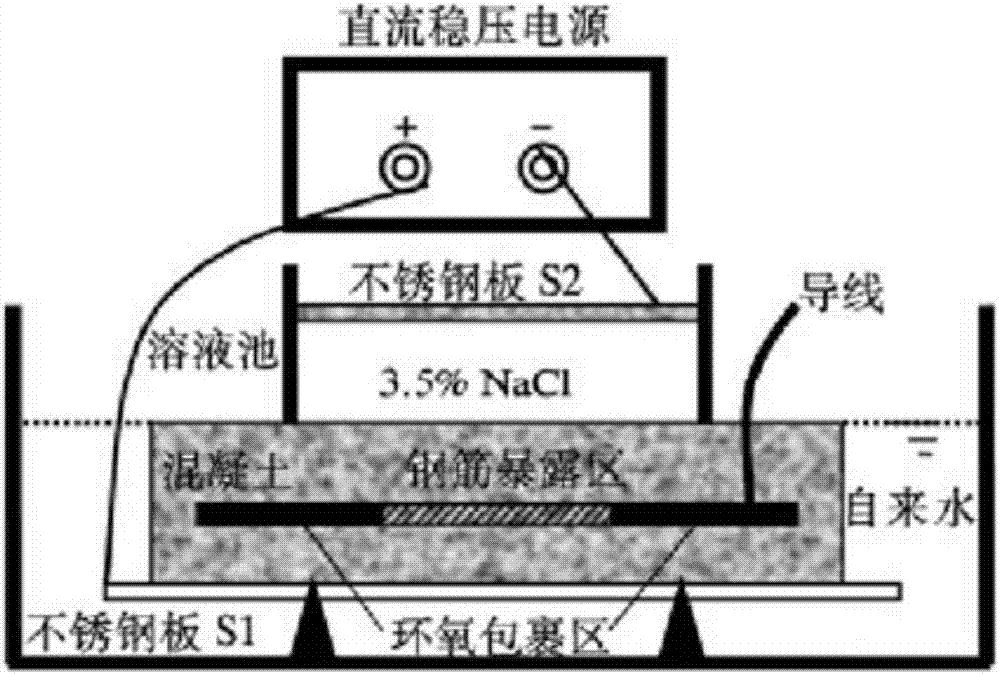

Exosmosis electricity acceleration type steel bar corrosion testing device and building method thereof

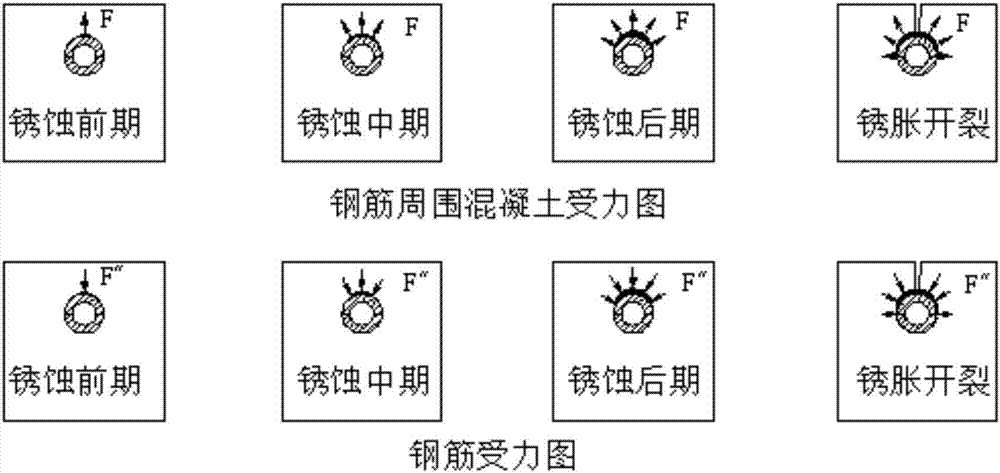

A technology for steel corrosion and testing device, which is applied in measurement device, preparation of test samples, weather resistance/light resistance/corrosion resistance, etc. It can solve the problem that the corrosion degree of steel corrosion parts cannot be detected, and the corrosion cracking of reinforced concrete does not conform to the actual situation of the project. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] In this embodiment, a 100×100×300mm 3 Test piece, and the inside of the test piece is provided with a threaded steel bar with a diameter of 25mm to build an extravasation electric accelerated steel corrosion test device as an example, specifying the specific structure and construction method of the test device of the present invention, the described extravasation electric accelerated steel corrosion test device The construction method includes the following steps:

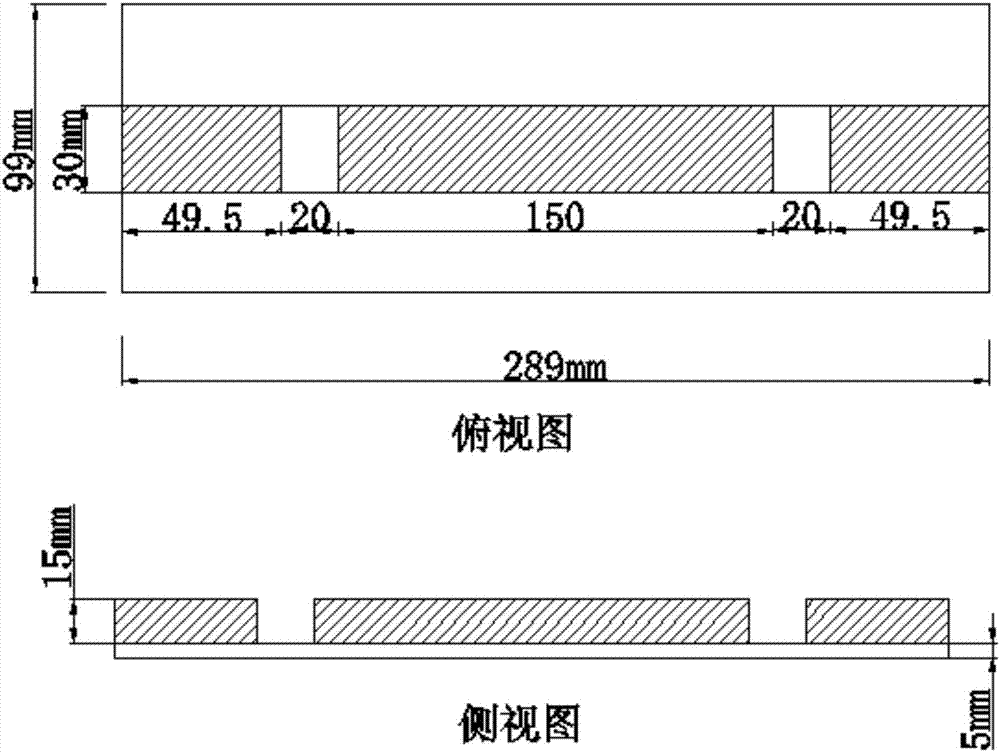

[0038] S1. Steel bar treatment: Cut the threaded steel bar with a diameter of 25mm into two symmetrical halves along the axial direction, dig out a semicircular groove with a diameter of 15mm in the middle of the cut steel bar, pickle the processed steel bar to remove rust, and then Put it in calcium hydroxide solution for neutralization, rinse it with clean water and dry it. After drying, use a steel brush to smooth the inner semicircular groove. After pretreatment, each half of the steel bar will Three pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com