Engine oil compound, engine oil and preparation method thereof

A technology of engine oil and composition, which is applied in the direction of lubricating composition, petroleum industry, base materials, etc., can solve the problems of high price, difficulty in meeting the performance requirements of high-end lubricating oil, high preparation cost, etc., and achieve control of sludge generation, high temperature resistance Excellent oxidation performance and the effect of extending oil drain intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

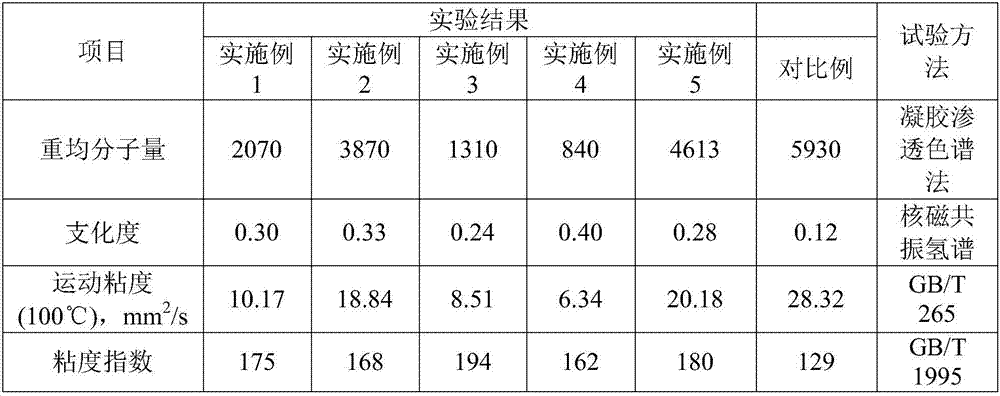

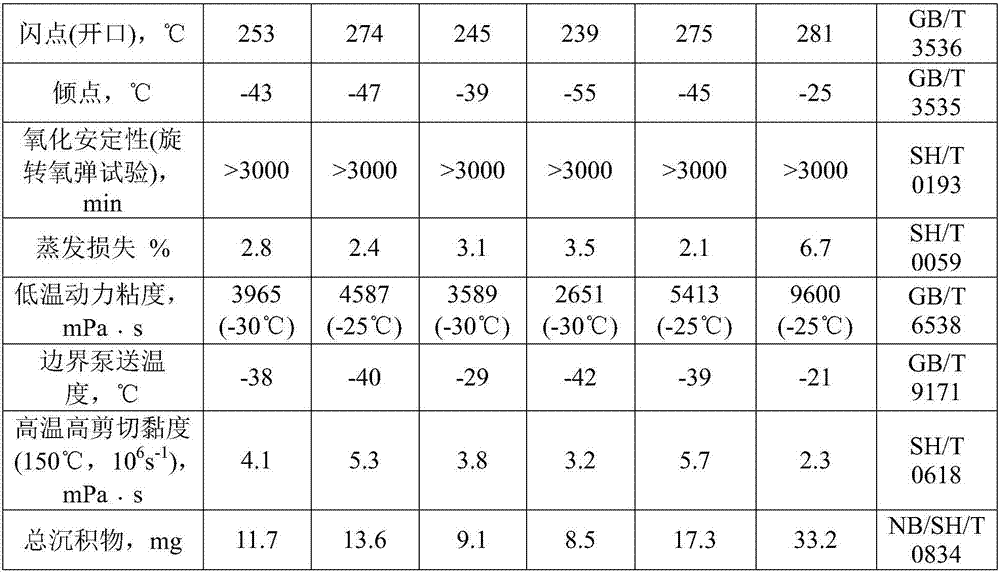

Embodiment 1

[0037] Preparation of Hyperbranched Polyethylene

[0038] Add 72 mg TaCl to a polymerization kettle equipped with a magnetic stirring bar 5 Catalyst, 0.2 mL cocatalyst EtAlCl 2 hexane solution (1 mol / L) and 10 mL of toluene, assemble a polymerization kettle under a nitrogen atmosphere, heat to 45 ° C, and feed ethylene at a constant pressure of 4 MPa. Keep stirring at 45°C for 16 hours, then terminate the reaction with methanol, remove the solvent and ethylene oligomers by vacuum distillation, dissolve the product again with chloroform, and pass through a silica gel column to obtain an oily hyperbranched polyethylene base oil. The weight average molecular weight of the product was 2070, and the degree of branching was 0.30.

[0039] Blending of engine oil

[0040] Take 95.98 parts of hyperbranched polyethylene base oil into the blending kettle, stir and heat to 50°C, add 2 parts of calcium sulfonate, 1 part of bisbutyrimide, 0.5 parts of zinc dialkyl dithiophosphate, poly ...

Embodiment 2

[0042] Preparation of Hyperbranched Polyethylene

[0043] Add 72 mg TaCl to a polymerization kettle equipped with a magnetic stirring bar 5 Catalyst, 0.1 mL cocatalyst Et 3 al 2 Cl 3 hexane solution (1 mol / L) and 10 mL of toluene, assemble a polymerization kettle under a nitrogen atmosphere, heat to 25 ° C, and feed ethylene at a constant pressure of 2 MPa. Keep stirring at 25°C for 16 hours, then terminate the reaction with methanol, remove the solvent and ethylene oligomers by vacuum distillation, dissolve the product again with chloroform, and pass through a silica gel column to obtain an oily hyperbranched polyethylene base oil. The weight average molecular weight of the product was 3870, and the degree of branching was 0.33.

[0044] Blending of engine oil

[0045] Take 96.65 parts of hyperbranched polyethylene base oil into the blending kettle, stir and heat to 50°C, add 1 part of high alkali value alkyl calcium salicylate, 1 part of polyisobutenyl succinimide, dial...

Embodiment 3

[0047] Preparation of Hyperbranched Polyethylene

[0048] Add 72 mg TaCl to a polymerization kettle equipped with a magnetic stirring bar 5 Catalyst, 1.0 mL cocatalyst EtAlCl 2 hexane solution (1 mol / L) and 10 mL of toluene, assemble a polymerization kettle under nitrogen atmosphere, heat to 75 ° C, and feed ethylene at a constant pressure of 5 MPa. Keep stirring at 75°C for 12 hours, then terminate the reaction with methanol, remove the solvent and ethylene oligomers by vacuum distillation, dissolve the product again with chloroform, and pass through a silica gel column to obtain an oily hyperbranched polyethylene base oil. The weight average molecular weight of the product was 1310, and the degree of branching was 0.24.

[0049] Blending of engine oil

[0050] Take 92.47 parts of hyperbranched polyethylene base oil into the blending kettle, stir and heat to 50°C, then add 3 parts of magnesium sulfonate, 3 parts of monosuccinimide, and 0.5 parts of 2,6-di-tert-butylphenol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| Branching factor | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com