Liquid optical transparent adhesive and preparation method thereof

An optically transparent adhesive and its production method technology, applied in the direction of adhesives, non-polymer organic compound adhesives, etc., can solve the problems of reduced screen brightness and contrast, messy light, etc., and achieve low shrinkage, low hardness, and long-lasting effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below.

[0021] The invention discloses a liquid optical transparent adhesive, which is composed of the following components in parts by weight: 40-70 parts of oligomer; 30-50 parts of acrylate active monomer; 1-5 parts of photoinitiator; 1-5 parts of auxiliary agent.

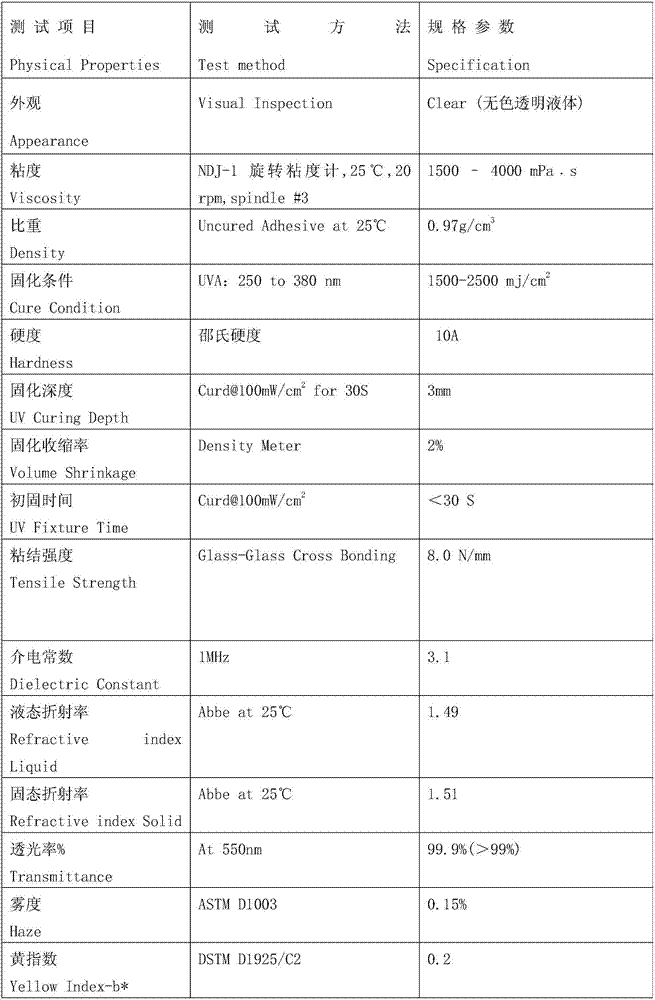

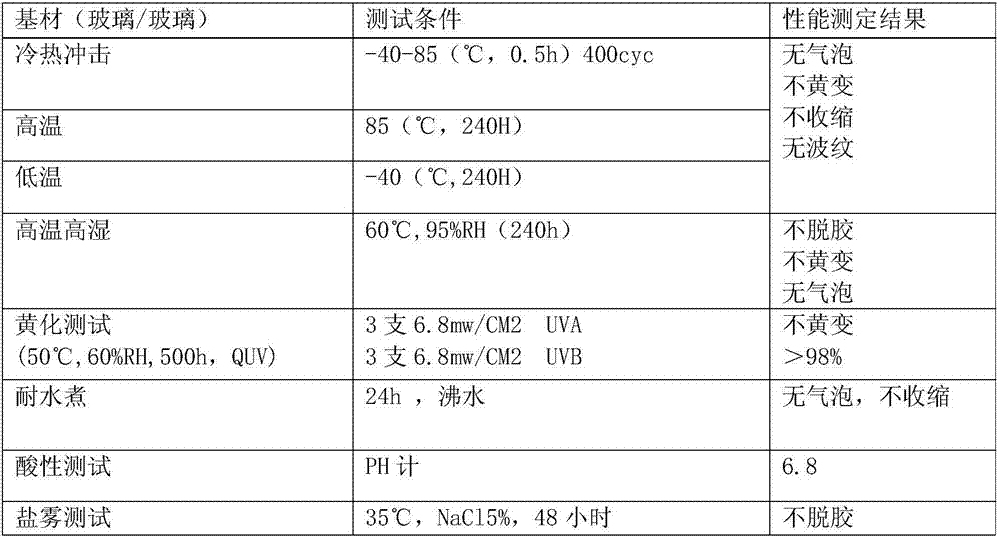

[0022] The oligomer is polyisoprene acrylate, polybutadiene acrylate or polystyrene adiene acrylate, the molecular weight is between 15000-40000, the functionality is 2-3, and it has a large molecular weight and low hardness. , Very low corrosion to ITO film, anti-yellowing, low shrinkage and other properties. The polyisoprene acrylate, polybutadiene acrylate or polystyrene-diene acrylate is a high-molecular-weight liquid rubber with a functionality of 2-3, capable of UV curing, and has a large molecular weight between 17000-35000 , low hardness, Shore hardness < 10A, volume shrinkage b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com