High-temperature-resistant, infrared radiation preventing and energy-saving coating

An energy-saving coating, anti-infrared technology, used in fire-resistant coatings, alkali metal silicate coatings, polyurea/polyurethane coatings, etc., can solve the problems of high temperature resistance, infrared radiation rate attenuation, infrared radiation rate attenuation, and short service life. , to achieve the effect of strong high temperature resistance, low crystal activity, and improved thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

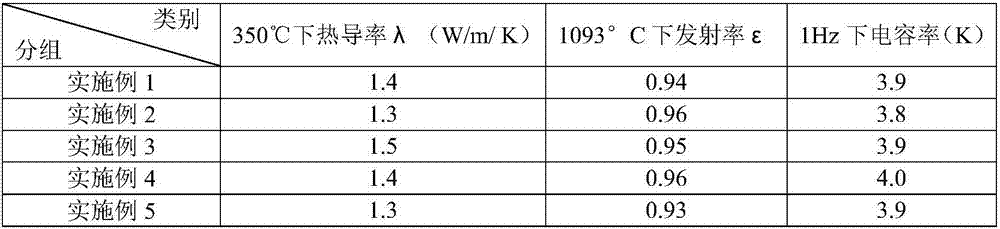

Embodiment 1

[0023] A high-temperature-resistant anti-infrared radiation rate attenuation energy-saving coating, which is composed of the following parts by weight: 30 parts of high-temperature and high-radiation powder, 10 parts of quartz powder, 5 parts of fused zirconia micropowder, 50 parts of water-based polyurethane resin, 5 parts of water, three parts 0.1 part of sodium polyphosphate, 0.15 part of trimethoxysilane coupling agent and 0.05 part of G60 defoamer produced by Sima Chemical.

Embodiment 2

[0025] A high-temperature-resistant anti-infrared radiation rate attenuation energy-saving coating, which is composed of the following parts by weight: 40 parts of high-temperature and high-radiation powder, 10 parts of quartz powder, 10 parts of fused zirconia micropowder, 30 parts of water glass, 10 parts of water, six partial 0.2 part of sodium phosphate, 0.3 part of trimethoxysilane coupling agent and 0.15 part of G60 defoamer produced by Sima Chemical.

Embodiment 3

[0027] A high-temperature-resistant anti-infrared radiation rate attenuation energy-saving coating is composed of the following parts by weight: 30 parts of high-temperature and high-radiation powder, 20 parts of quartz powder, 8 parts of fused zirconia micropowder, 20 parts of water-based polyurethane resin and 10 parts of silica sol, 12 parts of water, 0.15 part of polyethylene glycol type water reducer FS10 dispersant, 0.2 part of trimethoxysilane coupling agent and 0.1 part of G60 defoamer produced by Sima Chemical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com