Adhesive transparent conductive film for stealth of aircraft cockpit glass and preparation method thereof

A technology of transparent conductive film and cockpit glass, which is applied in the direction of coating, etc., can solve the problems of low light transmittance of indium tin oxide film layer, corrosion resistance of simple metal film, poor weather resistance and friction resistance, etc., to improve infrared stealth performance, Good flight visual effect, increase maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

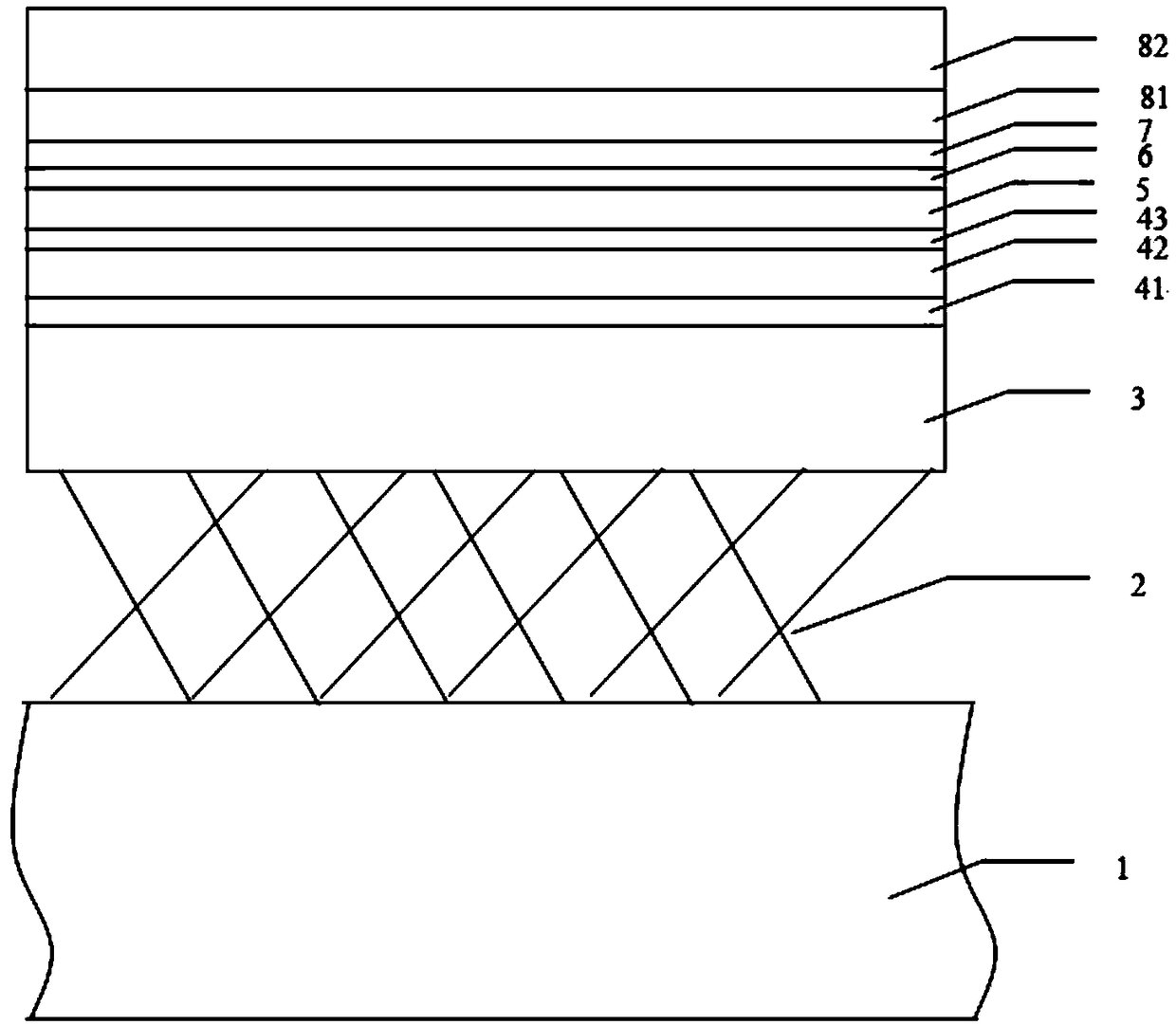

[0035] Such as figure 1 As shown, the present invention is used for the stealth of the aircraft cockpit glass instant paste type transparent conductive film, the instant paste type transparent conductive film used for the aircraft cockpit glass stealth comprises a flexible substrate, the first structural layer, the first stealth function layer 5 , the middle layer 6, the second stealth function layer and the second structure layer, and the instant sticking type transparent conductive film used for the stealth of the aircraft cockpit glass is followed by the flexible substrate, the first structure layer, and the first stealth function layer from the inside to the outside. 5. The middle layer 6, the second stealth function layer 7 and the second structural layer.

[0036] The first structural layer is used to prevent impurity ion elements in the flexible substrate from entering the first stealth functional layer 5 to affect the stealth effect, improve adhesion and comprehensivel...

Embodiment 2

[0055] The difference between embodiment 2 and embodiment 1 is: the instant paste type transparent conductive film used for the stealth of the aircraft cabin glass of the present invention, the instant paste type transparent conductive film is attached to the top of the aircraft cabin glass 1 through the adhesive layer 2, The material of the flexible base 3 is PI, and the thickness of the flexible base is 0.1 mm.

[0056] The first structural layer is composed of three continuous film layers, and the three continuous film layers include a first silicon nitride layer 41, a titanium oxide layer 42 and a first transparent conductive oxide layer 43; A structural layer is sequentially composed of a first silicon nitride layer 41, a titanium oxide layer 42, and a first transparent conductive oxide layer 43 from inside to outside;

[0057] The film thickness of the first silicon nitride layer 41 is 15 nm, the film thickness of the titanium oxide layer 42 is 12 nm, and the film thickn...

Embodiment 3

[0068] The difference between embodiment 3 and embodiment 1 is: the instant paste type transparent conductive film used for the stealth of the aircraft cabin glass of the present invention, the instant paste type transparent conductive film is attached to the top of the aircraft cabin glass 1 through the adhesive layer 2, The material of the flexible base 3 is PET, and the thickness of the flexible base is 0.2 mm.

[0069] The first structural layer is composed of three continuous film layers, and the three continuous film layers include a first silicon nitride layer 41, a titanium nitride layer 42 and a first transparent conductive oxide layer 43; The first structural layer is sequentially the first silicon nitride layer 41, the titanium nitride layer 42, and the first transparent conductive oxide layer 43 from the inside to the outside;

[0070] The film thickness of the first silicon nitride layer 41 is 10 nm, the film thickness of the titanium nitride layer 42 is 20 nm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com