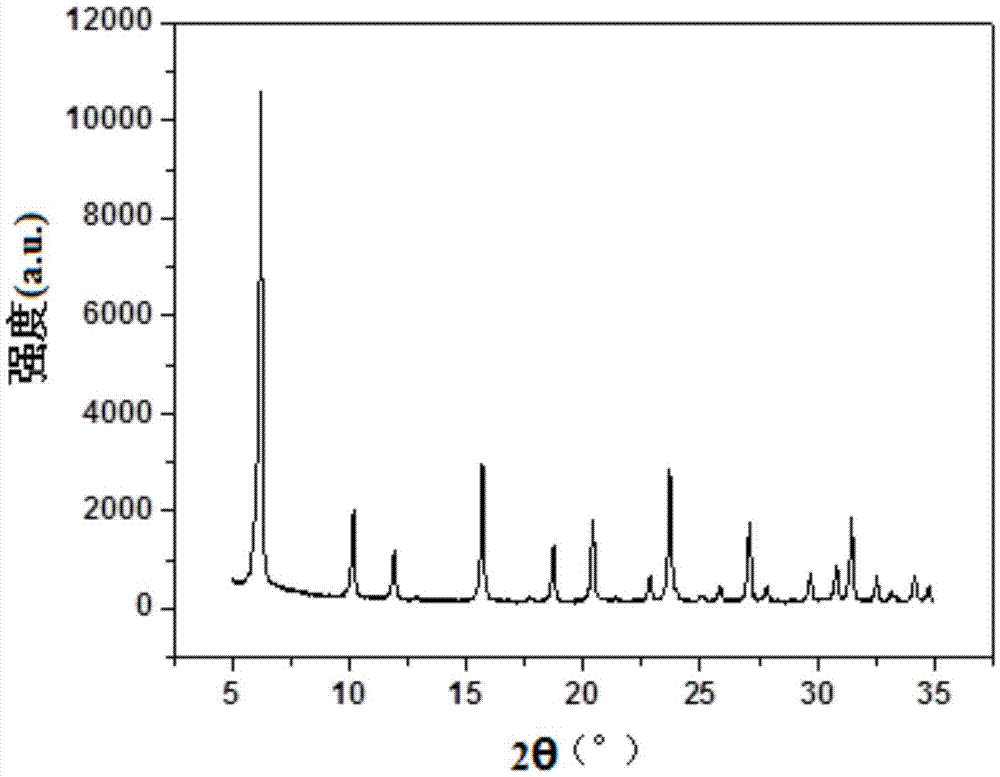

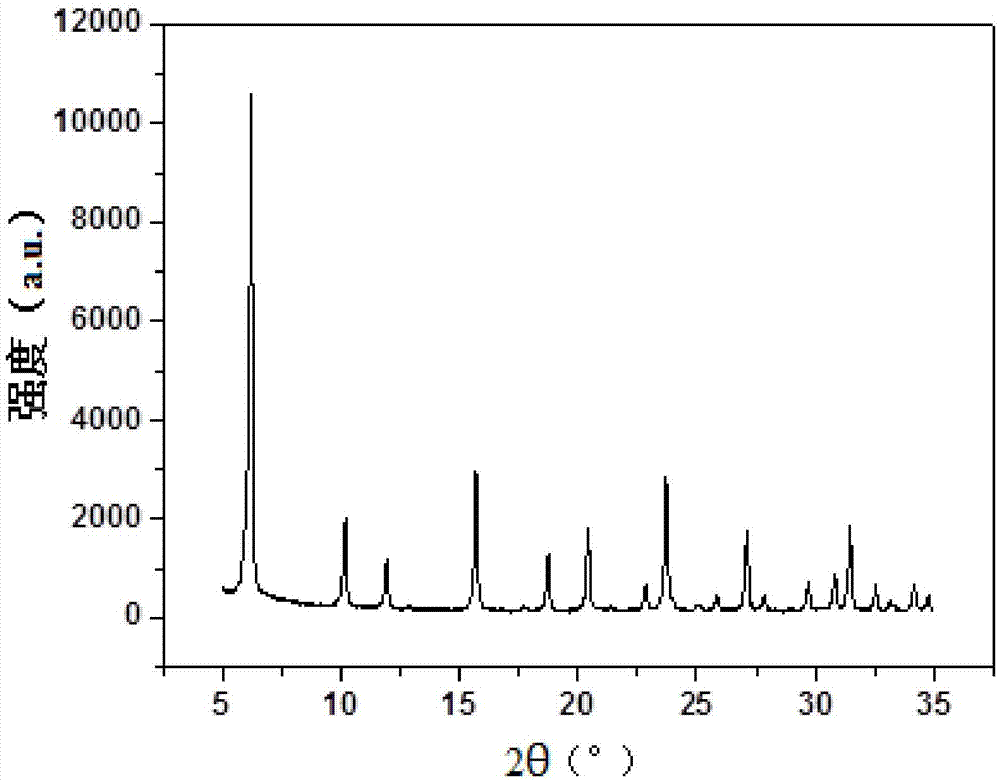

Y molecular sieve and preparation method thereof

A technology of molecular sieves and elements, which is applied in the field of inorganic materials and catalyst preparation, can solve the problems of relative crystallinity and silicon-aluminum ratio reduction of synthetic products, and achieve the effects of reduced energy consumption, improved preparation efficiency, and short crystallization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The present embodiment provides a kind of preparation method of Y molecular sieve, it comprises the following steps:

[0048] Get 75g water glass (SiO 2 The content is 28.45wt%, Na 2 O content is 8.89wt%), add 75g perbasic sodium metaaluminate (Na 2 O content is 21.11wt%, Al 2 o 3 Content is 3.16wt%), 34.09g tetrahydrofuran (analytical pure) and 30g water are mixed evenly, stirred at 33°C for 1h, aged for 16h, and made into a directing agent;

[0049] Get 200g water glass (SiO 2 The content is 28.45wt%, Na 2 O content is 8.89wt%), put into the beaker that is placed in 60 ℃ of water baths, under the condition of stirring, add 26.81g above-mentioned directing agent successively, 68.52g peralkali sodium metaaluminate (Na 2 O content is 21.11wt%, Al 2 o 3 Content is 3.16wt%) and 50g water, add 129.83g aluminum sulfate (Al 2 o 3 content is 7.60wt%) and stirred evenly to obtain a gel reaction mixture;

[0050] The above-mentioned gel reaction mixture was put into a...

Embodiment 2

[0053] The present embodiment provides a kind of preparation method of Y molecular sieve, it comprises the following steps:

[0054] Get 80g water glass (SiO 2 The content is 28.45wt%, Na 2 O content is 8.89wt%), add 40g perbasic sodium metaaluminate (Na 2 O content is 21.11wt%, Al 2 o 3 The content is 3.16wt%), 3.45g tetrahydrofuran (analytical pure) and 20g water are mixed evenly, stirred at 51°C for 1h, aged for 6h, and made into a directing agent;

[0055] During the preparation of the gel reaction mixture, the amount of raw materials and the order of addition remain unchanged, but after the directing agent and the high-alkali sodium metaaluminate solution are added to the water glass in sequence, stir for 8 hours, then add aluminum sulfate, and stir evenly Afterwards, the gel reaction mixture is obtained;

[0056] The above-mentioned gel reaction mixture was put into a reaction kettle, and then the reaction kettle was placed in a microwave heating device to stand sti...

Embodiment 3

[0059] The present embodiment provides a kind of preparation method of Y molecular sieve, it comprises the following steps:

[0060] Get 80g water glass (SiO 2 The content is 28.45wt%, Na 2 O content is 8.89wt%), add 40g perbasic sodium metaaluminate (Na 2 O content is 21.11wt%, Al 2 o 3 The content is 3.16wt%), 34.09g of ethanol (analytical grade) and 20g of water are mixed evenly, stirred at 21°C for 1h, aged for 6h, and made into a directing agent;

[0061] In the preparation process of the gel reaction mixture, the consumption of each raw material remains unchanged, but after the directing agent and the high alkali sodium metaaluminate solution are successively added to the water glass, stir for 48 hours, then add aluminum sulfate, and after stirring evenly, prepare Obtain gel reaction mixture;

[0062] Put the above gel reaction mixture into a reaction kettle, put the reaction kettle into a microwave heating device, crystallize at 80° C. for 60 min, then filter, wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com