Novel consolidated nano-diamond butadiene grinding disc and preparation technology thereof

A technology of nanodiamondene and grinding discs, which is applied in the field of grinding and polishing, can solve the problems of workpiece cleaning and subsequent processing, poor overall planarization effect, and difficult control of processing technology, etc., and achieves low cost, convenient cleaning and processing, and abrasive utilization. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

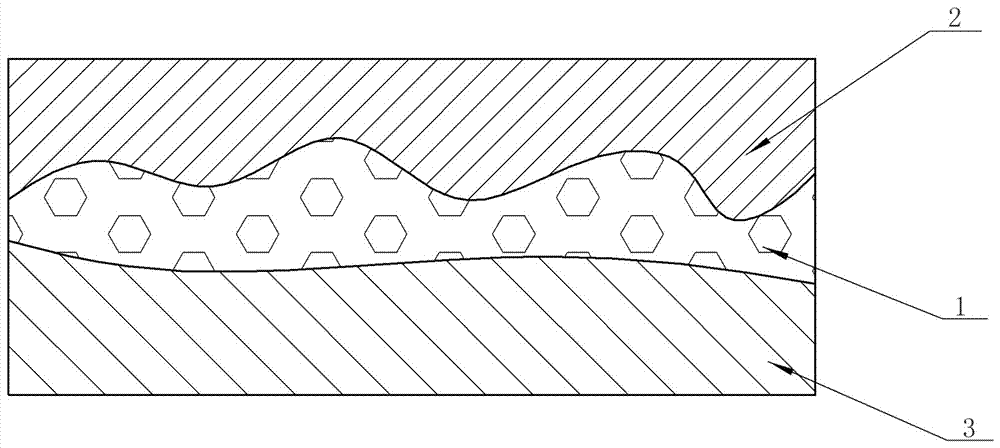

Image

Examples

Embodiment 1

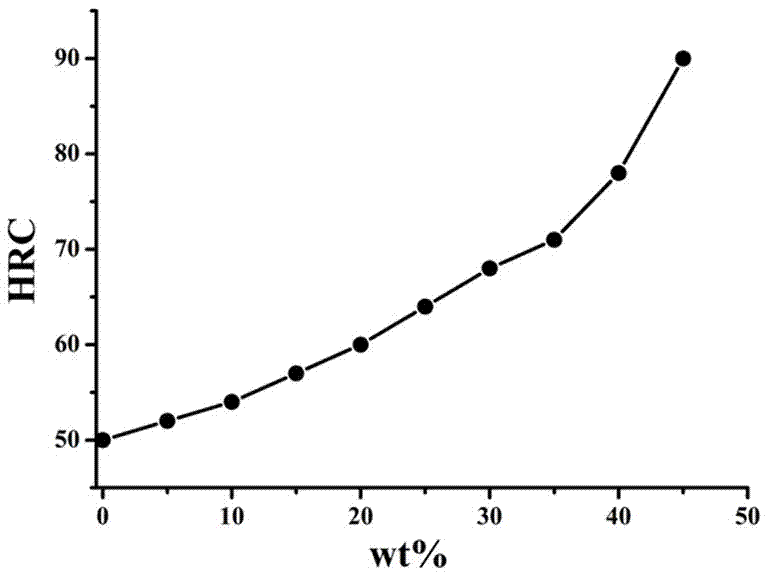

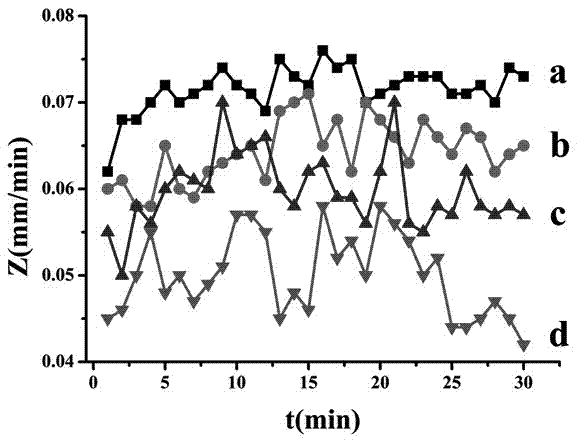

[0051] A novel solidified nano-diamantene grinding disc is made by adding nano-diamantene to basic raw materials, and the basic raw materials are made of the following components in weight percentage: Modified E-54 epoxy resin and methyltetrahydrophthalic anhydride ( MTHPA) 55%, N,N-dimethylbenzylamine 0.5%, plasticizer (dibutyl phthalate) 3.5%, filler (modified wollastonite) 35%, pore forming agent 6%, nano The amount of diamondene added is 30wt% of the base material, and the mass ratio of E-54 epoxy resin to methyltetrahydrophthalic anhydride is 10:9.

[0052]The pore-forming agent is a mixture of graphite and salt, and the mixing ratio of the two is 1:1.

[0053] The nano-diamantene is obtained by mixing nano-diamantene with four different particle sizes of 50nm, 100nm, 200nm, and 250nm according to the mass ratio of 1:2:3:4 and then undergoing the following treatment:

[0054] ①Ultrasonic alkaline cleaning: put the mixed nanodiamondene in an alkaline cleaning tank for ult...

Embodiment 2

[0078] A novel solidified nano-diamantene grinding disc is made by adding nano-diamantene to basic raw materials, and the basic raw materials are made of the following components in weight percentage: Modified E-54 epoxy resin and methyltetrahydrophthalic anhydride ( MTHPA) 60%, N,N-dimethylbenzylamine 1%, plasticizer | (dibutyl phthalate) 4%, filler (modified wollastonite) 30%, pore former 5%, The addition amount of nanodiamondene is 33wt% of the basic raw material, and the mass ratio of E-54 epoxy resin and methyltetrahydrophthalic anhydride is 10:9.

[0079] The pore-forming agent is a mixture of graphite and salt, and the mixing ratio of the two is 1:1-2.

[0080] The nano-diamantene is obtained by mixing nano-diamantene with four different particle sizes of 50nm, 100nm, 200nm, and 250nm according to the mass ratio of 2:3:4:5 and then undergoing the following treatment:

[0081] ①Ultrasonic alkaline cleaning: put the mixed nanodiamondene in the alkaline cleaning tank for ...

Embodiment 3

[0105] A new type of consolidated nano-diamantene grinding disc is made by adding nano-diamantene to basic raw materials. The basic raw material is made of the following components in weight percentage: Modified E-54 epoxy resin and methyltetrahydrophthalic anhydride 57 %, N,N-dimethylbenzylamine 1%, plasticizer (dibutyl phthalate) 4%, filler (modified wollastonite) 33%, pore-forming agent 5%, nanodiamondene The addition amount is 20wt% of the basic raw material, and the mass ratio of E-54 epoxy resin and methyltetrahydrophthalic anhydride is 10:9.

[0106] The pore-forming agent is a mixture of graphite and salt, and the mixing ratio of the two is 1:1-2.

[0107] Described nanodiamondene is the same as embodiment 1.

[0108] The preparation method of the novel consolidated nano-diamantene grinding disc is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com