Caesarean section nursing belt

A technology for nursing belts and caesarean section, which is applied in the field of medical equipment, can solve the problems of no antibacterial and anti-inflammation, and achieve the effects of reducing pain, high chemical stability, and removing odors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

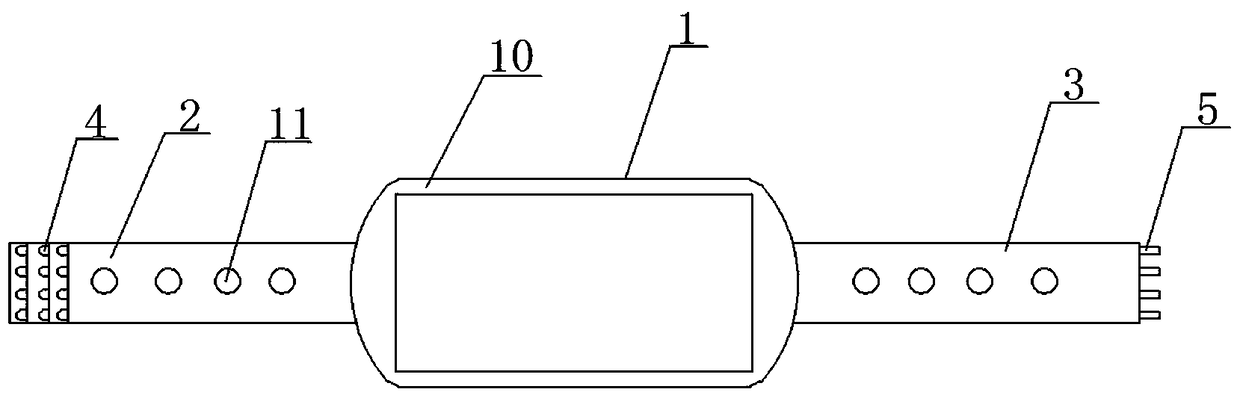

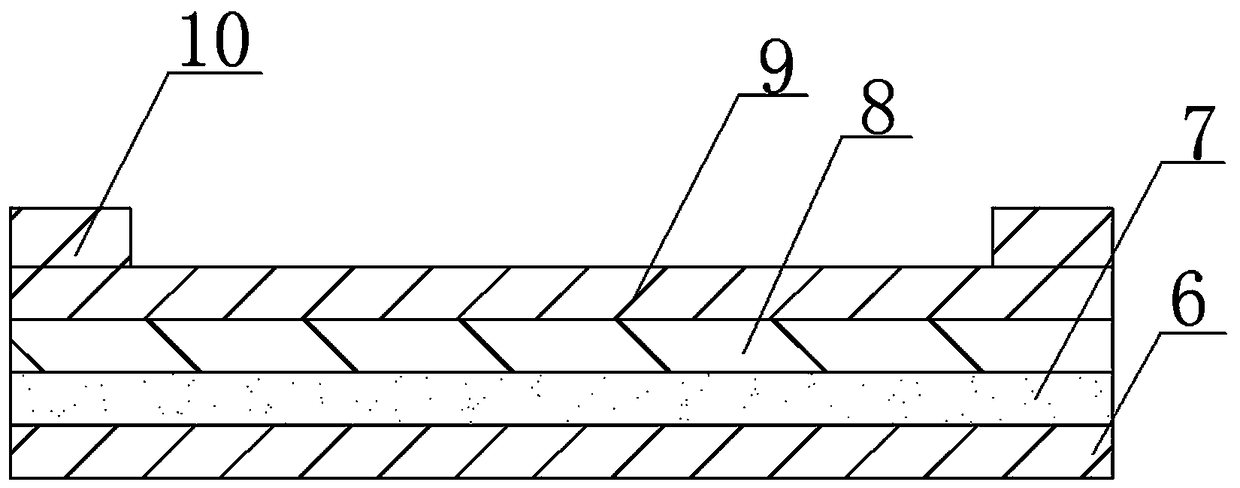

[0038]A cesarean nursing belt, comprising a abdominal belt 1, a left belt 2 and a right belt 3 located on both sides of the belt, the left belt 2 is provided with multiple rows of buckles 4, and the right belt 3 is provided with buckles 3 Matching hook 5, abdominal belt 1 includes antibacterial fiber layer one 6, traditional Chinese medicine layer 7, heating layer 8 and antibacterial fiber layer two 9 from bottom to top, wherein heating layer 8 is provided with electric heating between the upper and lower layers of non-woven fabrics sheet; the surrounding edge of the antibacterial fiber layer-6 is provided with an isolation layer 10, the isolation layer 10 is bonded on the antibacterial fiber layer-6, and can be removed, and the left protective belt 2 and the right protective belt 3 are provided with ventilation holes 11 for heat dissipation and breathable. When using the caesarean section care belt, at the initial stage of use, under the effect of the isolation belt 10, the a...

Embodiment 2

[0046] Embodiment 2 is the same as the structure of the caesarean section nursing belt in embodiment 1, and the difference is:

[0047] Wherein the antibacterial fiber is prepared by the following steps:

[0048] In the first step, the ZnCl 2 and TiCl 4 After mixing the anhydrous ethanol solution at a molar ratio of 2:1, adjust the pH to 9.0, stir and react at 65°C for 14h, dry at 90°C, and grind to obtain ZnO / TiO 2 Powder;

[0049] The second step is to mix ZnO / TiO2 powder, n-propanol, tetrabutyl titanate and γ-aminopropyltriethoxysilane in a weight ratio of 1:9:9:0.1, and then coat it on the bamboo charcoal fiber After drying at 55°C, bake at 160°C for 35 minutes to obtain antibacterial fibers.

[0050] The Chinese medicine layer is to place Chinese medicine powder between the upper and lower layers of non-woven fabrics. The Chinese medicine powder is made of the following raw materials in parts by weight: 22 parts of cockscomb, 22 parts of sea octopus, 28 parts of Agrim...

Embodiment 3

[0053] Embodiment 3 is the same as the structure of the caesarean section nursing belt in embodiment 1, and the difference is:

[0054] Wherein the antibacterial fiber is prepared by the following steps:

[0055] In the first step, the ZnCl 2 and TiCl 4 After mixing the anhydrous ethanol solution at a molar ratio of 1.5:1, adjust the pH to 9.0, stir and react at 70°C for 13h, dry at 95°C, and grind to obtain ZnO / TiO 2 Powder;

[0056] The second step is to mix ZnO / TiO2 powder, n-propanol, tetrabutyl titanate and γ-aminopropyl triethoxysilane in a weight ratio of 1:9:9:0.2, and then coat it on the bamboo charcoal fiber After drying at 50°C, bake at 170°C for 30 minutes to obtain antibacterial fibers.

[0057] The Chinese medicine layer is to place Chinese medicine powder between the upper and lower layers of non-woven fabrics. The Chinese medicine powder is made of the following raw materials in parts by weight: 24 parts of cockscomb, 24 parts of sea octopus, 26 parts of Ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com