Compound acid stabilizer and ultrahigh-voltage auxiliary stabilization method for anthocyanidin

An assisted stabilization and anthocyanin technology, applied in ultra-high pressure food processing, acid-containing food ingredients, food science and other directions, can solve the problems of long reaction time, low efficiency, general stabilization effect, etc., to reduce the loss of anthocyanin, Efficient extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 anthocyanin extraction

[0039] Prepare a mixed extract of 0.1-0.5% hydrochloric acid and 55-75% ethanol, beat grapes, black wolfberries, blueberries, elderberry red, black currant, purple carrots and red cabbage, grind in a colloid mill at 2000-4000r / min for 10-20min, use High-voltage pulse electric field, under the conditions of liquid-material ratio 5-9:1 (w / w, electric field strength 10-20kvcm, pulse number 4-10, extract anthocyanin with mixed extract, centrifuge at 3000-5000 r / min After 5-15 minutes, take the supernatant and concentrate under reduced pressure at 40-55°C. After purification by D101 macroporous resin, concentrate under reduced pressure and freeze-dry to obtain anthocyanins.

Embodiment 2

[0040] Embodiment 2 Vitis vinifera extract

[0041] Arctic Red Mountain grape, provided by Tonghua Wine Research Institute. On September 28, 2015 (110 days after the grapes bloomed), random samples were taken and frozen.

[0042] Arctic Red Mountain grape anthocyanins: Take a large number of Arctic Red Mountain grapes from the same batch, remove the stalk and core, beat and grind, use high-voltage pulse electric field to mix 1% hydrochloric acid-65% ethanol with a liquid-to-material ratio of 8.5:1 (w / w, The electric field strength is 15kvcm, the pulse number is 4 conditions to extract the anthocyanins from Vitis vinifera, centrifuge at 4500r / min for 10 min, take the supernatant, concentrate under reduced pressure, purify with D101 macroporous resin, concentrate under reduced pressure, and freeze-dry to obtain the Vitis vinifera flower green pigment.

Embodiment 3

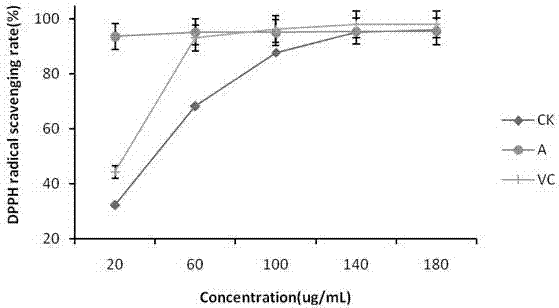

[0043] Embodiment 3 anthocyanin stabilizer

[0044] The anthocyanin stabilizer is composed of the following components, D-gluconic acid (analytical pure), ferulic acid (biological reagent) purchased from Aladdin Industrial Company (Aladdin Industrial Company); caffeic acid (biological reagent) Shanghai Jinsui Biotechnology Ltd.

[0045] For every 4 parts of purified anthocyanin (anthocyanin content ≥ 25%, calculated as cyanidin 3-O-G), the amount of added stabilizer:

[0046] D-gluconic acid (50%, w / w) 8-16 parts

[0047] Ferulic acid 4-8 parts

[0048] Caffeic acid 2-6 parts

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com