A grounding ring and reaction chamber for limiting plasma leakage

A plasma and grounding ring technology, applied in the direction of circuits, discharge tubes, electrical components, etc., can solve the problems of insufficient plasma and radio frequency leakage restrictions, non-grounding, etc., to improve the shielding effect, ensure the air flow, and increase the longitudinal distance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

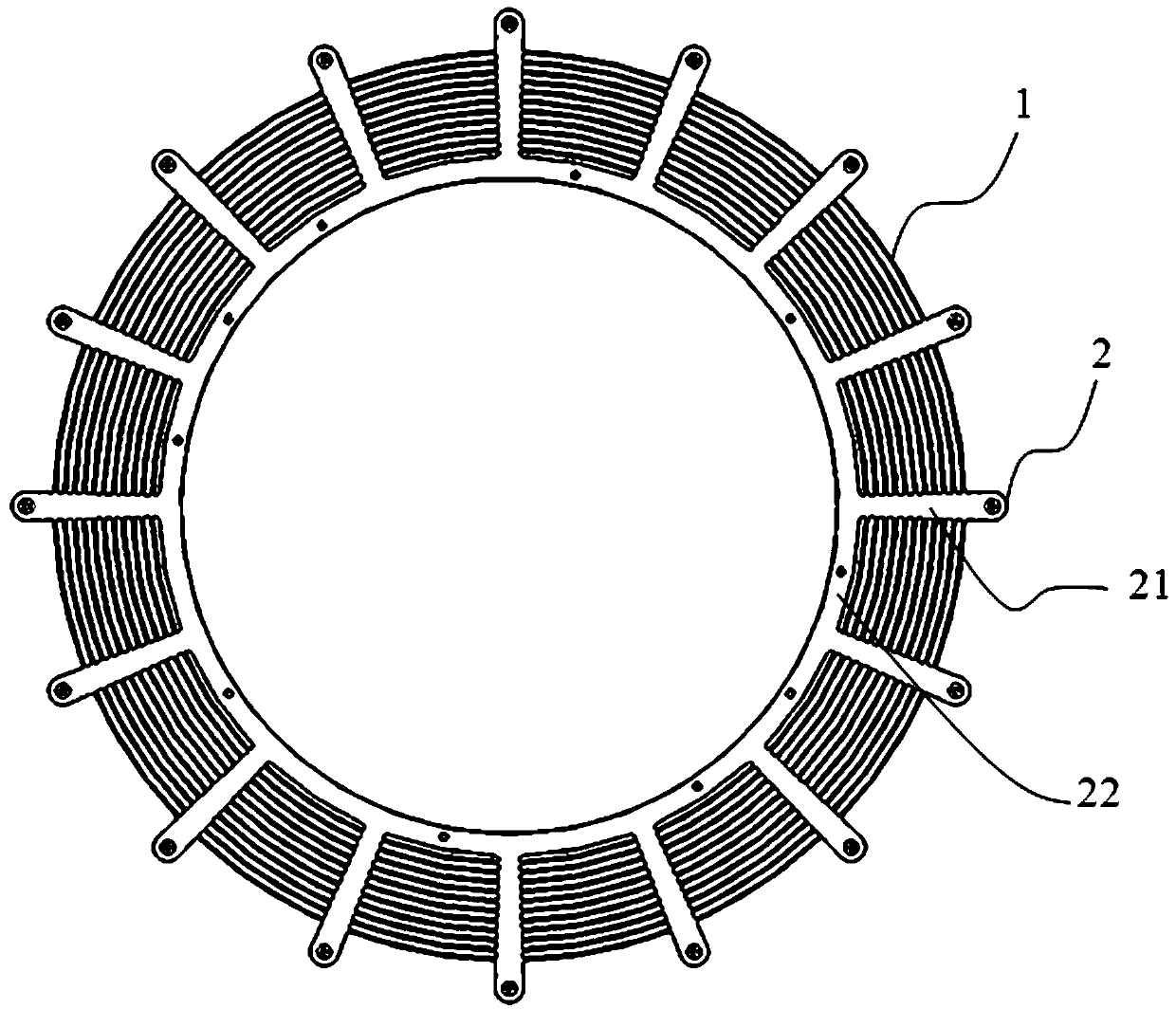

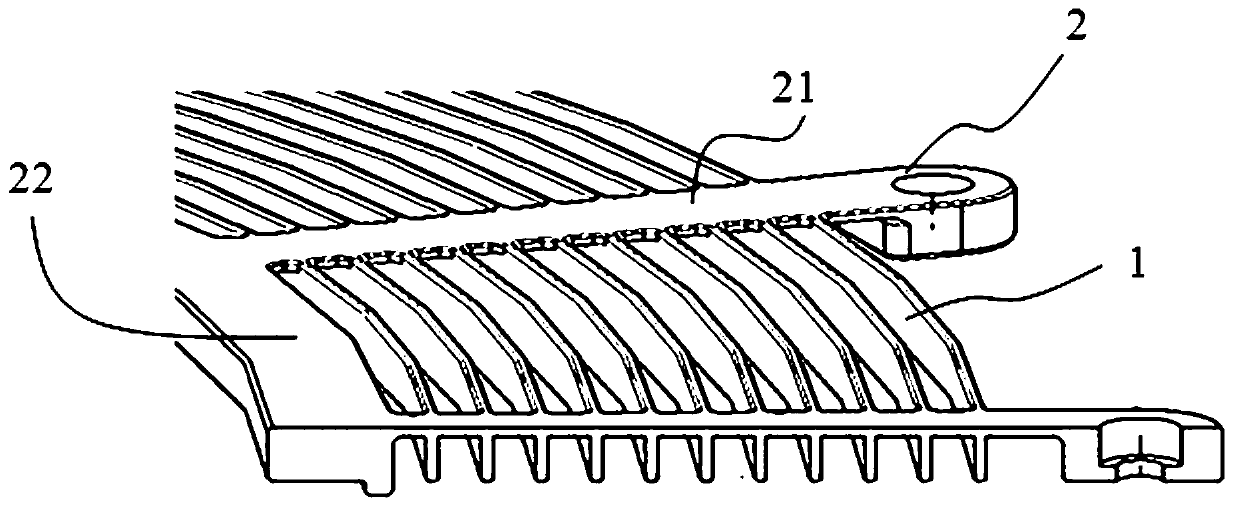

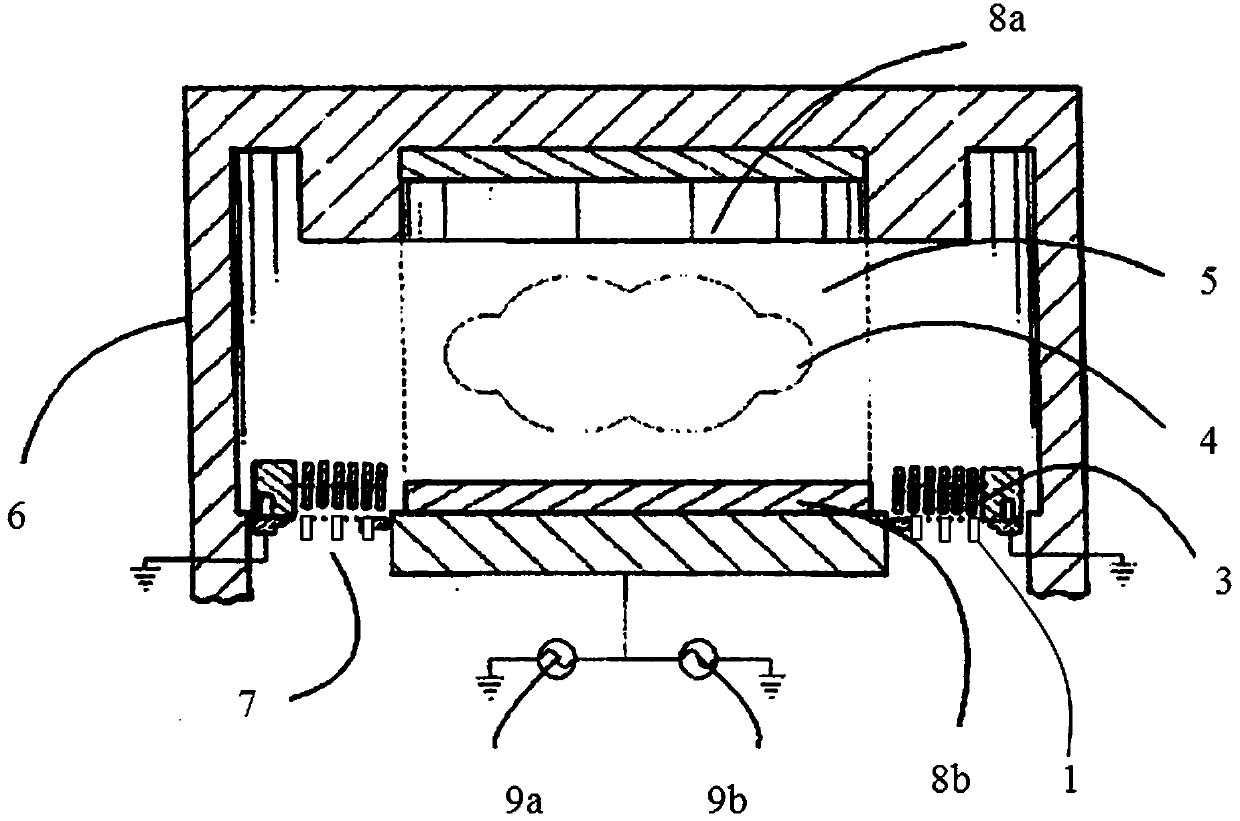

[0040] A grounding ring to limit plasma leakage, such as image 3 As shown in , it is arranged in a reaction chamber cavity 6, which contains a confinement ring 3, and the confinement ring 3 comprises a plurality of concentric rings; as figure 1 , 2 As shown, the grounding ring includes a plurality of concentric grounding rings 1 with gradually increasing radii to form a dense ring structure, and the grounding ring is located below the confinement ring 3; every two adjacent concentric grounding rings 1 The spacing between them is equal, and its spacing is twice the spacing between two adjacent concentric rings on the confinement ring 3, that is, if the spacing between adjacent concentric rings of the confinement ring 3 is 1.5mm, the phase of the grounding ring The distance between adjacent concentric grounding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com