Coalbed methane continuous hydration solidification and storage and transportation integrated device and method

A coalbed methane and hydration technology, which is applied in gas/liquid distribution and storage, liquid distribution, transportation or transfer device, distribution device, etc. problems, to achieve the effect of convenient control, wide application range and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

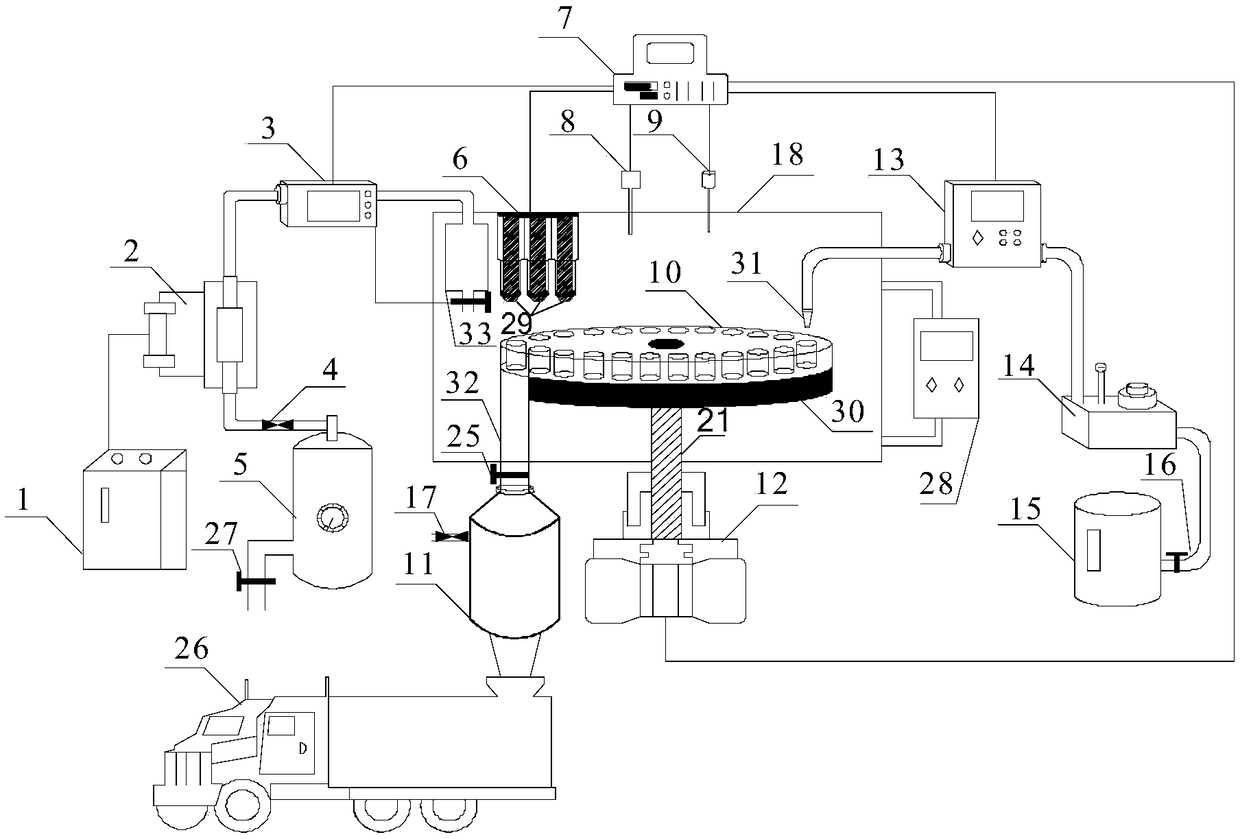

[0038] Specific implementation mode one: refer to Figure 1 to Figure 8 Describe this embodiment in detail. The continuous hydration solidification and storage and transportation integrated device for coalbed methane described in this embodiment includes a gas delivery and pressure automatic control device, a high-pressure automatic water delivery spray device, an industrial computer 7, and a servo high-pressure seal replacement device. 6. The roulette clip-type reactor 10, the jacketed high-pressure sealed temperature box 18 and the circulating refrigerant controller 28,

[0039] Both the servo high-pressure sealed displacement device 6 and the disk clip reactor 10 are located in the jacketed high-pressure sealed temperature box 18,

[0040] The gas delivery and pressure automatic control device is used to deliver the gas to the jacketed high-pressure sealed temperature box 18 at a constant pressure,

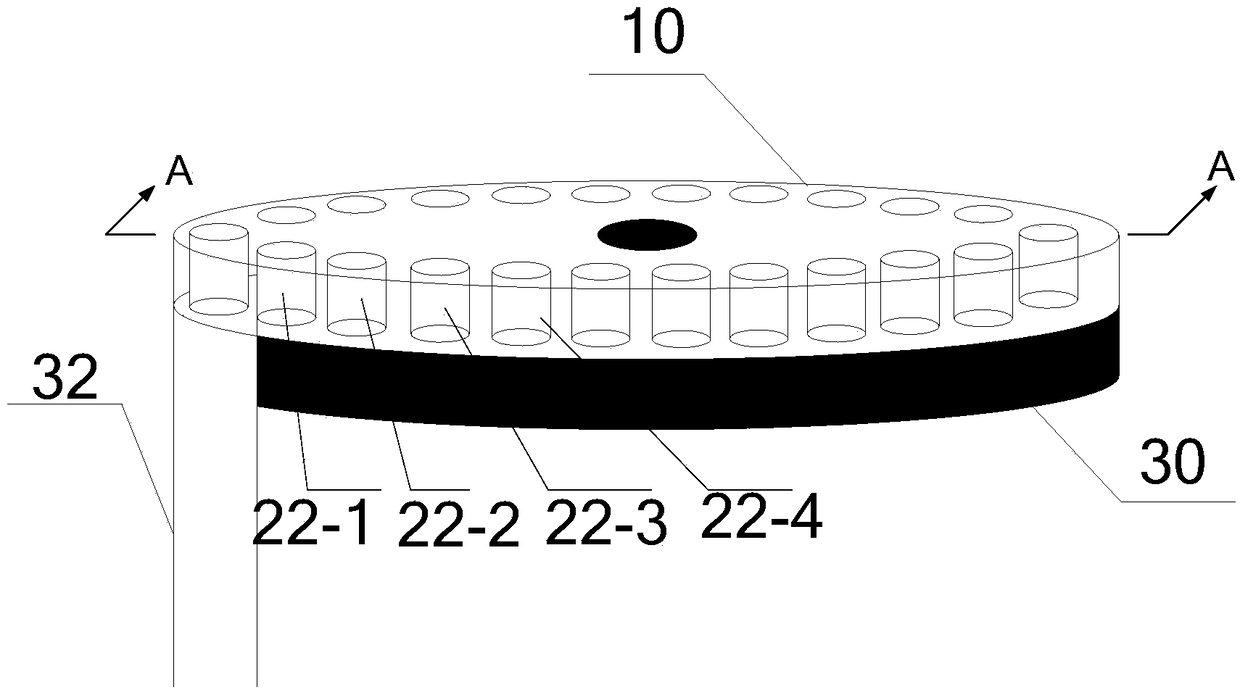

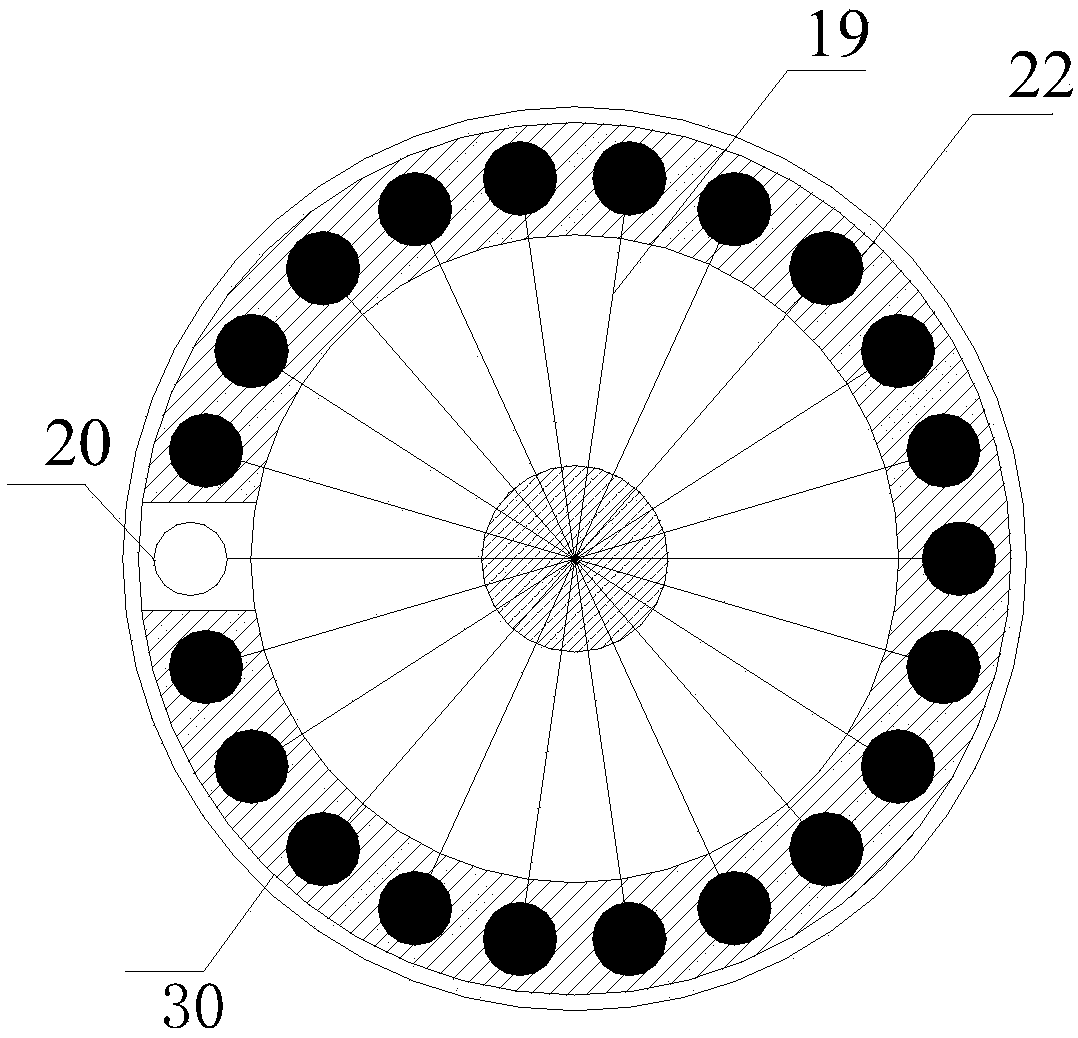

[0041] The roulette clip reactor 10 includes a hub 19 of a coalbed methan...

specific Embodiment approach 2

[0053] Specific implementation mode two: refer to figure 2 , Figure 4 and Figure 5 Describe this embodiment in detail. This embodiment is a further description of the coalbed methane continuous hydration solidification and storage and transportation integration device described in Embodiment 1. In this embodiment, the servo high-pressure sealing displacement device 6 includes three displacement mechanisms 29 and the servo rotating structure 24,

[0054] Three displacement mechanisms 29 are located directly above the sampling port 20, and the three displacement mechanisms 29 are connected to the bottom end of the servo rotation structure 24, and the top end of the servo rotation structure 24 is located on the top of the jacketed high-pressure sealed temperature box 18,

[0055] The servo rotating structure 24 is used to rotate under the control of the industrial computer 7, thereby driving three displacement mechanisms 29 to rotate,

[0056] The first displacement mechani...

specific Embodiment approach 3

[0059] Specific implementation mode three: refer to figure 1 and image 3 Describe this embodiment in detail. This embodiment is a further description of the coalbed methane continuous hydration solidification and storage and transportation integration device described in Embodiment 1. In this embodiment, it also includes a servo fixed-frequency rotation controller 12 and a turntable power axis 21,

[0060] The axis of the upper surface of the turntable power axis 21 is the center of the hub 19 of the coal bed gas hydration solidification dish,

[0061] The servo fixed-frequency rotation controller 12 drives the hub 19 of the coalbed methane hydration solidification dish to rotate through the power axis 21 of the turntable.

[0062] In this embodiment, the coalbed methane hydration solidification dish hub 19 is connected to 22 coalbed methane hydration solidification dishes 22, and the coalbed methane hydration solidification dish hub 19 rotates to drive the 22 coalbed metha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com