Polyamide silver-plated fiber and preparation method thereof

A polyamide fiber, silver-plated fiber technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve problems such as harm, teratogenicity, carcinogenicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides the invention provides a kind of preparation method of polyamide silver-plated fiber, comprises the following steps:

[0032] sensitizing polyamide fibers in a sensitizing solution to obtain sensitized fibers;

[0033] dissolving silver ammonia solution and diethyltriaminepentaacetic acid in water, adjusting the pH value of the solution to 9.8-10.2 to obtain a plating solution;

[0034] The sensitized fiber is silver-plated in a mixed solution including plating solution and glucose to obtain polyamide silver-plated fiber.

[0035] The invention sensitizes the polyamide fiber in a sensitizing solution to obtain the sensitized fiber. In the present invention, the polyamide fiber is preferably nylon 6, nylon 66 or nylon 610. In the present invention, there is no special requirement on the source of the polyamide fiber, and the source of the polyamide fiber well-known to those skilled in the art can be used, specifically, the commercially available ...

Embodiment 1

[0052] Cleaning: prepare 500mL of 1wt% NaOH solution, and pour all the solution into a 1L beaker. 20 g of virgin fibers of nylon 6 were immersed in the solution. The solution was heated to 80°C and kept stirring for 1h for alkali washing. Put the alkali-washed fibers into deionized water and wash them with stirring for 3 times, each time for 10 minutes. It is enough to detect that the pH value of the treated water is close to neutral.

[0053] Sensitization: Weigh 4.0 grams of alkali-washed nylon 6 fibers and immerse them in 1% SnCl 4 In absolute ethanol solution, sonicate for 20 minutes in an ultrasonic instrument. After the fiber was taken out, it was washed 3 times with deionized water. Use silver nitrate to detect that there is no white precipitate in the water that has washed the fiber.

[0054] Preparation of plating solution: Weigh 1 g of silver nitrate, add 20 mL of deionized water to dissolve it, and add 27 wt % ammonia water dropwise to the silver nitrate soluti...

Embodiment 2

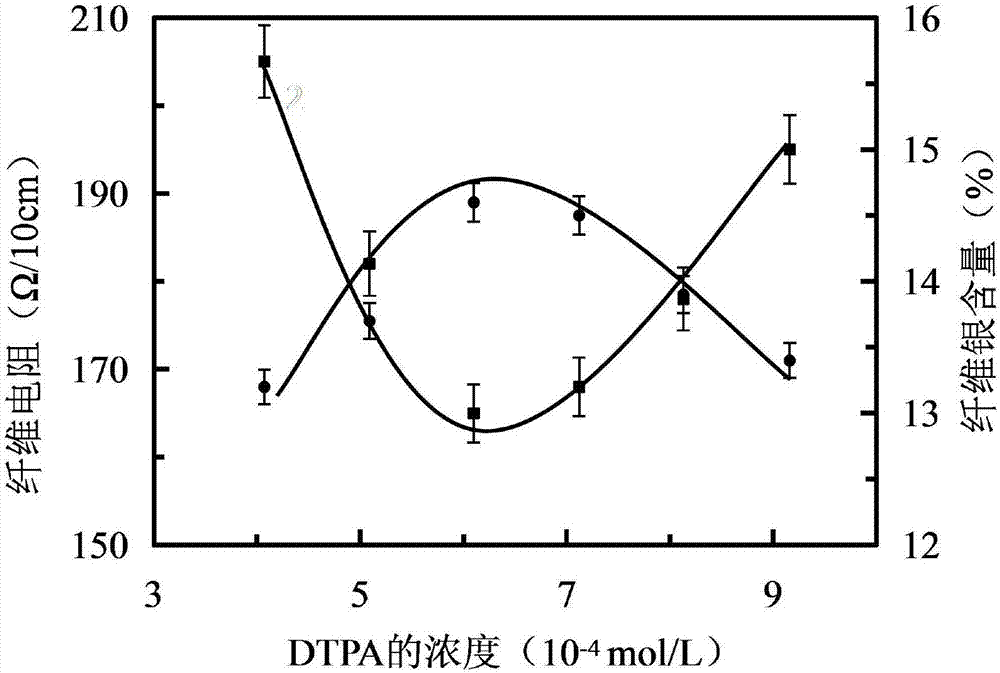

[0064] Except the change of DTPA concentration in the plating solution, all the other schemes are consistent with embodiment 1, research the influence of DTPA concentration on silver-plated fiber resistance and silver content, the result is as follows figure 1 shown. figure 1 It is the effect of different DTPA concentrations on the resistance and silver content of the silver-plated fiber in Example 2 of the present invention.

[0065] Depend on figure 1 It can be seen that when the concentration of DTPA is 5×10 -4 ~7×10 -4 When mol / L, the silver-plated fiber has the characteristics of low resistance and high silver content, the resistance value is 165-180Ω / 10cm, and the silver content is 14-14.75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com