Transgenic algae strain with high yield of nano polyphosphate body and preparation method thereof

A technology of polyphosphoric acid and polyphosphoric acid, which is applied in the field of genetic engineering, can solve the problems of adverse effects on microalgae growth kinetics, low quality of expression products, and difficulty in inducing expression, so as to achieve green production methods and research and utilization value High, simple and convenient method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Acquisition of the target gene

[0032] Specific primer design:

[0033] ppk Front primer: CCCAAGCTTGAAGGAGATAAAAAGTATATGTCCTCTGCG

[0034] ppkBack primer: CGGGGTACCCCTAATCCAAGCTGTCCTGGAG

[0035] Hind III and Kpn I restriction sites were added to the front and back primers respectively, and the RBS sequence of the GAAGGAG sequence was added to the front primer.

[0036] PCR conditions: 50 μL reaction system, 94°C for 5 min, (94°C for 30 s, 60°C for 40 s, 1 min and 72°C) for 30 cycles; 72°C for 10 min.

[0037] The target gene was purified and cloned by conventional methods for later use.

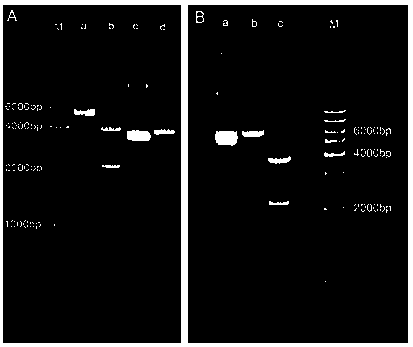

[0038] 2) Construction of the recombinant pSyn_1 plasmid: the pSyn_1 plasmid and the target gene were digested with Hind III and Kpn I, and the digested products were purified and ligated. 100 ng of the pSyn_1 plasmid and ppk 500 ng of the gene was ligated with T4 DNA ligase at 16°C for 3 h. The ligated plasmid was cloned by conventional methods, digested with restriction e...

Embodiment 2

[0042] 1) Acquisition of the target gene

[0043] Specific primer design:

[0044] ppk Front primer: CCCAAGCTTGAAGGAGATAAAAAGTATATGTCCTCTGCG

[0045] ppk Back primer: CGGGGTACCCTAATCCAAGCTGTCCTGGAG

[0046] Hind III and Kpn I restriction sites were added to the front and back primers respectively, and the RBS sequence of the GAAGGAG sequence was added to the front primer.

[0047] PCR conditions: 50 μL reaction system, 94°C for 5 min, (94°C for 30 s, 60°C for 40 s, 1 min and 72°C) for 30 cycles; 72°C for 10 min.

[0048] The target gene was purified and cloned by conventional methods for later use.

[0049] 2) Construction of the recombinant pSyn_1 plasmid: the pSyn_1 plasmid and the target gene were digested with Hind III and Kpn I, and the digested products were purified and ligated. 100 ng of the pSyn_1 plasmid and ppk 1 μg of gene was ligated with T4 DNA ligase at 16°C for 1 h. The ligated plasmid was cloned by conventional methods, digested with restriction enzyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

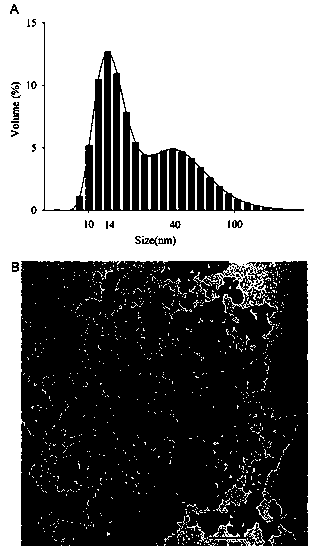

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com