Compound solidifier for mucky soil and application thereof

A composite curing agent, silty soil technology, applied in application, soil protection, fertilizer mixture, etc., can solve the problems of strength attenuation, limited excitation effect of mineral powder-solidified soil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] It is 6.8% to get organic matter content, and water content is the silty soil sample 1 of 87.1%, before test, remove soil sample impurity, take by weighing 600g soil sample, add different amount of silty soil composite curing agent (each component The weight percentages are: cement 46%, slag 34%, fly ash 15%, triethanolamine 5%), the mixture is stirred evenly to make 3 parallel cylinder samples of φ39.1×80mm, standard maintenance. The 14-day and 28-day unconfined compressive strengths are obtained as shown in Table 2:

[0033]Table 2 Soil sample 1 curing strength table

[0034]

Embodiment 2

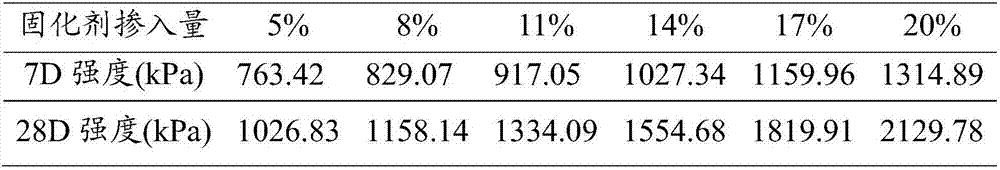

[0036] Getting organic matter content is 7.1%, and water content is the muddy soil sample 2 of 89.5%, before test, remove soil sample impurity, take by weighing 600g soil sample, add different amount of muddy soil composite curing agent (each component The weight percentages are: cement 46%, slag 34%, fly ash 15%, triethanolamine 5%), the mixture is stirred evenly to make three φ39.1×80mm cylindrical parallel samples, standard curing. The 14-day and 28-day unconfined compressive strengths are obtained as shown in Table 3:

[0037] Table 3 Soil sample 2 curing strength table

[0038]

Embodiment 3

[0040] It is 7.1% to get organic matter content, and water content is the muddy soil sample 3 of 91.1%, before test, remove soil sample impurity, take by weighing 600g soil sample, add different amount of muddy soil composite curing agent (each component The weight percentages are: cement 46%, slag 34%, fly ash 15%, triethanolamine 5%), the mixture is stirred evenly to make three φ39.1×80mm cylindrical parallel samples, standard curing. The 14-day and 28-day unconfined compressive strengths are obtained as shown in Table 4:

[0041] Table 4 Soil sample 3 curing strength table

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com