Method for preparing nitrogen-rich carbon-coated cobalt-containing compound without solvent

A cobalt compound, solvent-free technology, which is applied in the field of carbon coating material preparation, can solve the problems of difficult product separation, large amount of solvent used, complicated steps, etc., and achieves the effects of overcoming the amount of solvent, simple operation and short process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

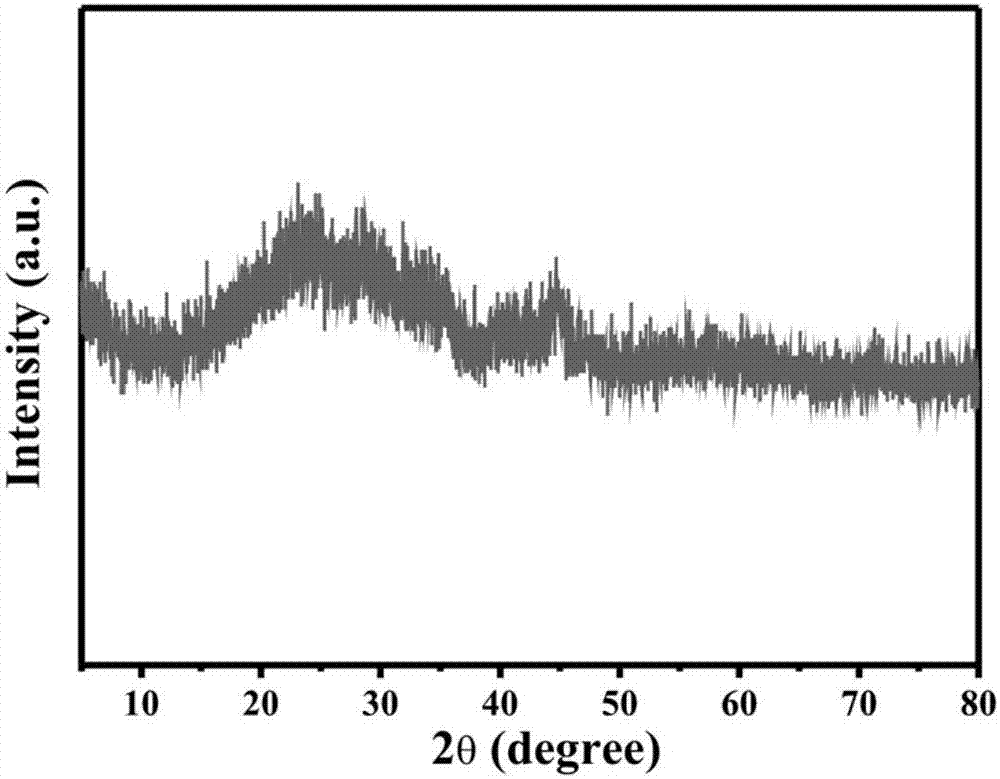

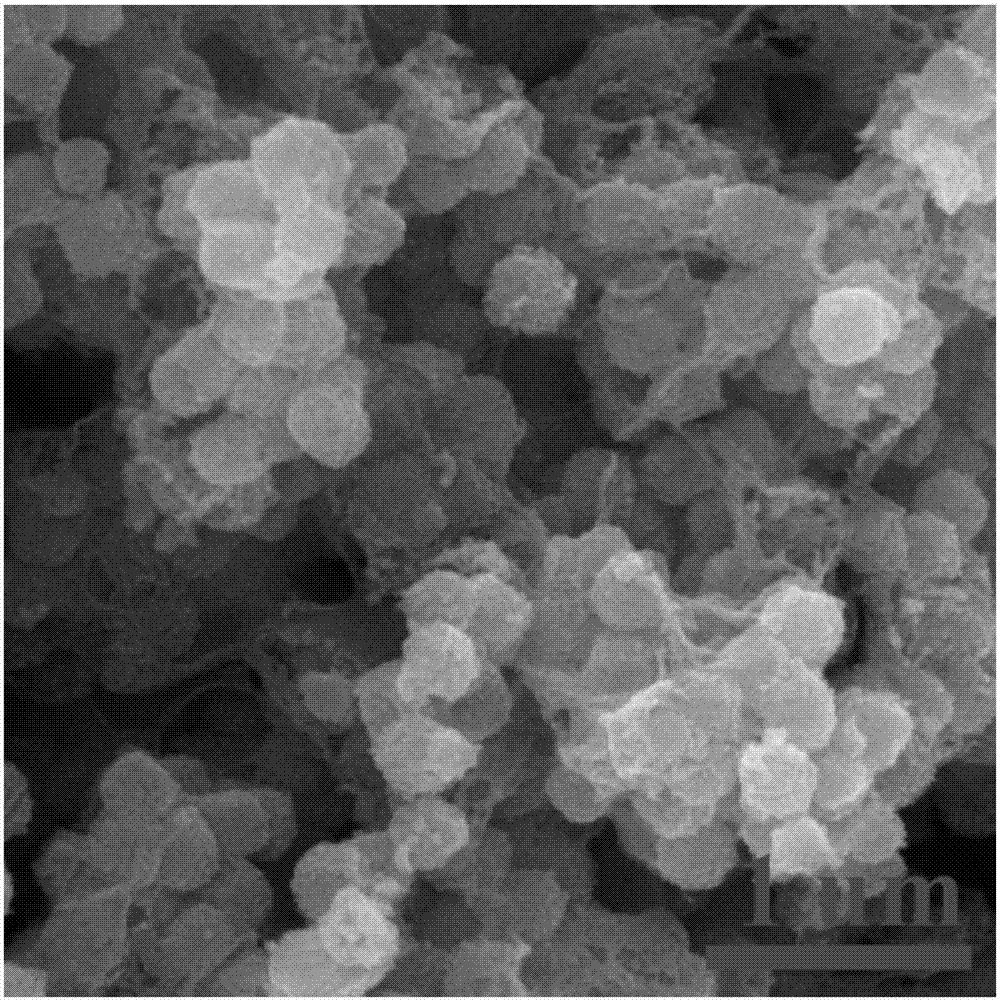

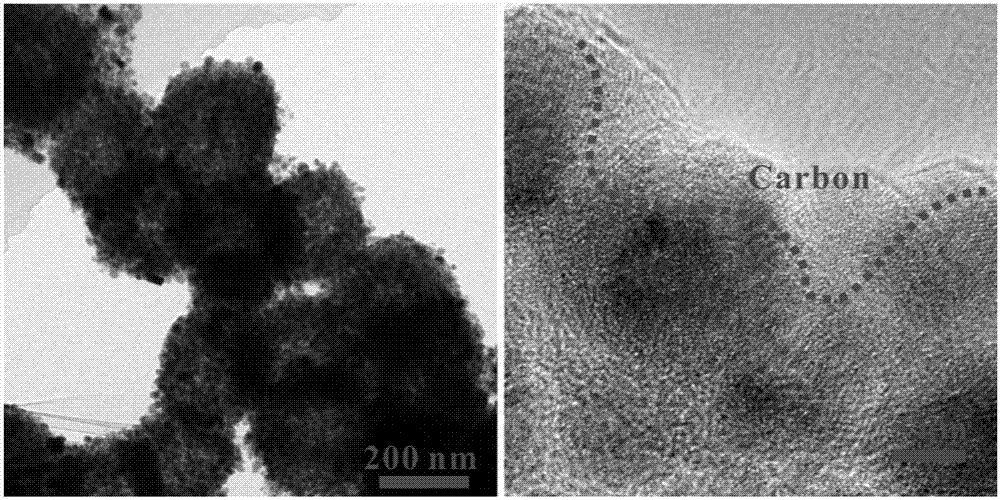

[0028] 120mg hollow nano-CoSnO 3 Mix and grind with 200mg 2-methylimidazole, place in a 100mL reaction kettle, seal, react at 200°C for 12h, after the reaction, cool, and directly calcinate at 700°C under the protection of argon, with a heating rate of 5°C per minute, About 100 mg of black solid was obtained. figure 1 It is its XRD picture, it can be observed that the cobalt-based compound coated with nitrogen-rich carbon prepared by this method and its precursor cobalt-containing compound have the same characteristic peaks, indicating that the type and crystal form of the substance before and after coating have not changed, and The diffraction peak of carbon is obviously found in it, which shows the reliability of the coating method. figure 2 It is its scanning electron microscope photo, and it can be seen that the cobalt-containing compound coated with nitrogen-rich carbon is composed of many nanocubes with a diameter of about 100nm, and a black carbon film is covered on t...

Embodiment 2

[0034] Mix and grind 150mg CoO and 500mg 2-methylimidazole, place it in a 100mL reactor and seal it at 180°C for 24h, after the reaction is completed, heat up at 10°C / min to 500°C in an argon atmosphere for 1h to obtain About 150mg of the product, the obtained nitrogen-rich carbon-coated CoO has a specific surface area of 268.5m 2 g -1 , greater than the specific surface area of CoO (35m 2 g -1 ), the carbon content is 38%, the nitrogen content is about 12%, and the surface carbon layer thickness is about 35nm.

Embodiment 3

[0038] Mix and grind 100mg CoS and 100mg benzodimethylimidazole, put it in a 50mL reactor, seal it at 180°C for 12h, after the reaction, lower the temperature at 10°C / min to 500°C for 1h in an argon atmosphere After the reaction, about 80 mg of nitrogen-enriched carbon-coated material was obtained. The thermogravimetric results showed that the carbon content was 35%, the nitrogen content was about 10%, and the specific surface area was 367.6m 2 g -1 , the particle size is mainly distributed around 200nm, and the surface carbon layer thickness is around 3nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com