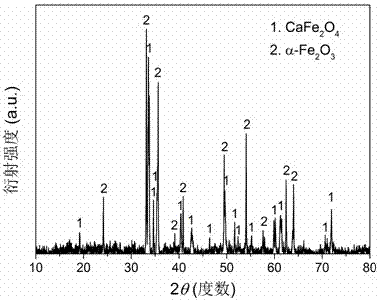

Doped CaFe2O4@alpha-Fe2O3 heterojunction composite photocatalyst, and preparation method and applications thereof

A doped, heterojunction technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of high cost, reduce the preparation cost, Reduced usage, cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Take 20 g of dried and ground converter sludge (wherein the mass percentage of TFe is 56.5%, and the mass percentage of CaO is 12.5%), add it to 200 mL of HCl solution with a concentration of 3 mol / L, and stir the acid in a water bath at 70 ° C. Decompose for 1 hour, stirring at a speed of 500 rpm, let the reacted solid-liquid mixture stand at room temperature for 10 hours, filter out insoluble matter to obtain a clear acid solution, and detect the concentration of Fe ions and Ca ions in the acid solution.

[0032] (2) Pour the acid solution obtained in step (1) into a beaker, add 5 mL of 30% hydrogen peroxide dropwise, stir for 1 h in a water bath at 70° C., add 40 g of sodium oxalate and continue stirring for 1 h to obtain a clear mixed solution.

[0033] (3) In the mixed solution of step (2), dropwise add NaOH solution with a concentration of 1mol / L to adjust the pH to 5, stir for 0.5h and then move it into the reaction kettle, heat water at 150°C for 8h, and cool...

Embodiment 2

[0038] (1) Take 20 g of dried and ground converter sludge (the mass percentage of Tfe is 56.5%, and the mass percentage of CaO is 12.5%), add it to 170 mL of HCl solution with a concentration of 3.5 mol / L, and stir in a water bath at 80 °C Acid hydrolysis for 2 hours, with a stirring speed of 400 rpm. The reacted solid-liquid mixture was allowed to stand at room temperature for 15 hours, and the insoluble matter was filtered off to obtain a clear acid solution. The concentrations of Fe ions and Ca ions in the acid solution were detected.

[0039] (2) Pour the acid solution prepared in step (1) into a beaker, add 5 mL of 30% hydrogen peroxide dropwise, stir for 0.5 h in a water bath at 80°C, add 40 g of sodium oxalate and continue stirring for 2 h to obtain a clear mixed solution .

[0040] (3) Add KOH solution with a concentration of 0.5mol / L dropwise to the mixed solution in step (2) to adjust the pH to 4.5, stir for 1 hour, then move it into the reaction kettle, heat it in w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com